Aluminum calcium master alloy AlCa5 10 15 20 25 35 alloys

Aluminum calcium master alloy AlCa5 10 15 20 25 35 alloys

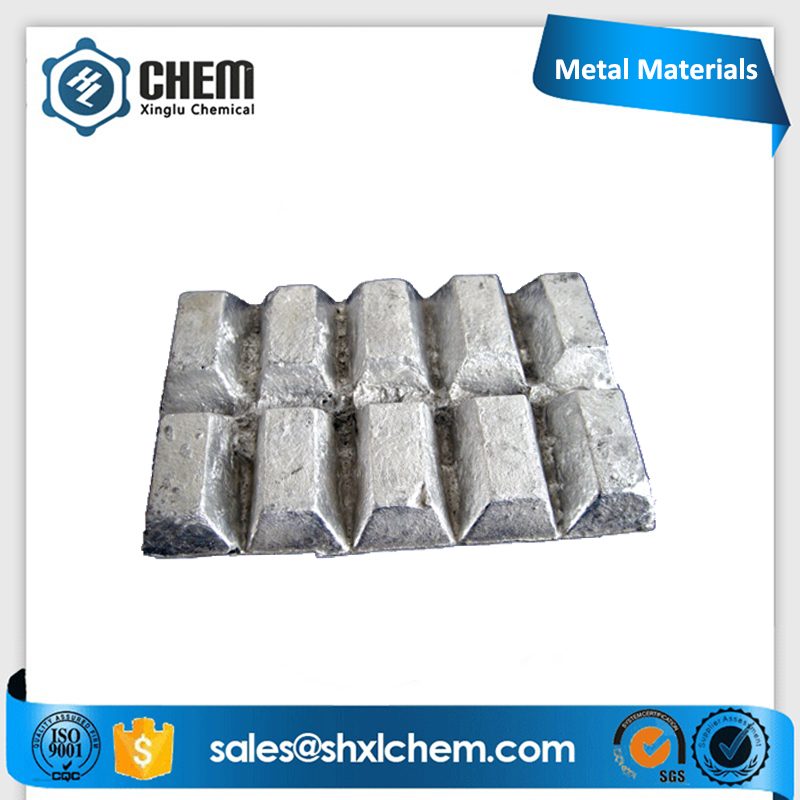

Master alloys are semi-finished products, and can be formed in different shapes. They are pre-alloyed mixture of alloying elements. They are also known as modifiers, hardeners, or grain refiners based on their applications. They are added to a melt to achieve the disired result. They are used instead of a pure metal because they are very economical and save energy and production time.

| Product Name | Aluminum calcium master alloy | |||||

| Standard | GB/T27677-2011 | |||||

| Content | Chemical Compositions ≤ % | |||||

| Balance | Si | Fe | Mn | Ca | Mg | |

| AlCa10 | Al | 0.30 | 0.05 | 0.02 | 9.0~11.0 | 0.15~0.20 |

| AlCa15 | Al | 0.30 | 0.03 | 0.02 | 14.0~16.0 | 0.15~0.20 |

| AlCa25 | Al | 0.30 | 0.05 | 0.02 | 23.0~27.0 | 0.15~0.20 |

| AlCa35 | Al | 0.30 | 0.05 | 0.02 | 33.0~37.0 | 0.15~0.20 |

| Applications | 1. Hardeners: Used for enhancing physical and mechanical properties of metal alloys. 2. Grain Refiners: Used for controlling the dispersion of individual crystals in metals to produce a finer and more uniform grain structure. 3. Modifiers & Special Alloys: Typically used to increase strength, ductility and machinability. |

|||||

| Other Products | AlMn, AlTi, AlNi, AlV, AlSr, AlZr, AlCa, AlLi, AlFe, AlCu, AlCr, AlB, AlRe, AlBe, AlBi, AlCo, AlMo, AlW, AlMg, AlZn, AlSn, AlCe, AlY, AlLa, AlPr, AlNd, AlYb, AlSc, etc. | |||||