Ka palapala noika hiʻuʻonaMa ka laweʻana i ka laweʻana i ka alumini alloy i laweʻia ma mua. ʻOiai ua hoʻomakaʻo Kina i ka noiʻi a me ke noiʻana o kēiaʻano wale nō i loko o ka makahiki 1960, ua ulu wikiwiki. Ua hana nuiʻia ka nui o nā hana ma luna o ka noiʻiʻana ma ka hana pono, a me nā wahi o nā mea waiwai a me nā mea waiwaiʻoi aku ka mīkini. ʻO nā lako māmā māmā

◆ ◆ ◆ hana hana o ka honua o ka honua i loko o ka alumini a me nā allunumum a allay ◆ vel

Ua loaʻa i ka mana o Rare ka Honua,ʻoi aku ka hoʻohaʻahaʻa haʻahaʻa, a me keʻano kūikawā a me nā allinumLanthanum), Ce (Kipuka), Y (yttrium) a sc (Scandium). Hoʻohui pinepineʻia lākou i loko o ka wai alumini me nā modifiers, e hoʻopili ana i nā mea a me nā mea hana a me nā mea hana, e hoʻomaikaʻi i keʻano, e hoʻomaikaʻi i ka palaoa, e hoʻomaikaʻi i ka palaoa, eʻoluʻolu

01ʻO ka hoʻomaʻemaʻeʻana i ka Honua

E like me ka nui o nā hau a me nā mea e hoʻopiliʻia ai ka maʻi a me nā mea hoʻonaninani a me nā mea hoʻonaninani. ʻO Molten Alminim, ka hoʻemiʻana o PINhole a me ka posterity Nitrogen Form restictory compounds, i laweʻia ma keʻano o ka slag ma ke kaʻina hana e hoʻomaʻemaʻe ai i keʻano alumini.

Ua hōʻike ka hoʻomaʻamaʻaʻana i ka honua i ka hopena o ka hōʻemiʻana i ka manaʻo o ka hydrogen, ka oxygen a me ka sultinum a me nā alumina Hoʻohui i ka 0.1% ~ 0.3% restinity e like me ka nui o nā bilinile hana i ka slag a laweʻia, no laila e hoʻomaʻemaʻe i nā wai alumini

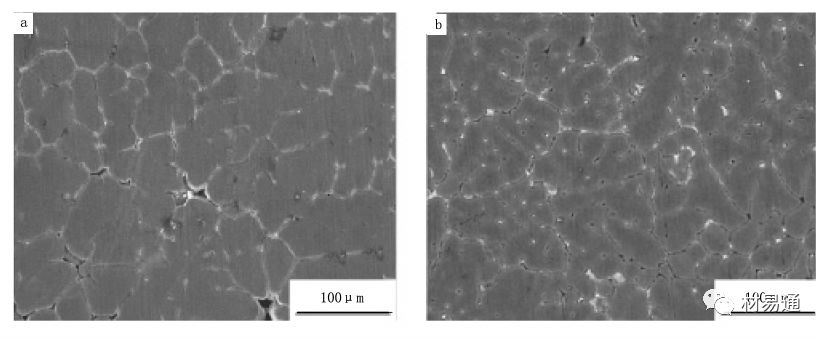

Fig. 1 sem morphology o 7075 alloy me kaʻole a w (re) = 0.3%

A. ʻAʻole i hoʻohuiʻiaʻo res; b. Hoʻohui w (re) = 0.3%

02Metamorphism o ka Honua

Ua hōʻike nuiʻiaʻo Rare Moving i nā moduke a me nā mea kūʻai aku i ka pili o ka corsene ʻO kēlā aluminum atom, a me kāna mau waiwai e hana ikaika ana. ʻO ka melting i loko o nā wai alumini he maʻalahi loa e hoʻopiha i nā hemahema o ka nui o keʻano a me ka manawa o ka uluʻana o ka nui o ka'ōpū ma waena o nā māla i waena o nā grans.

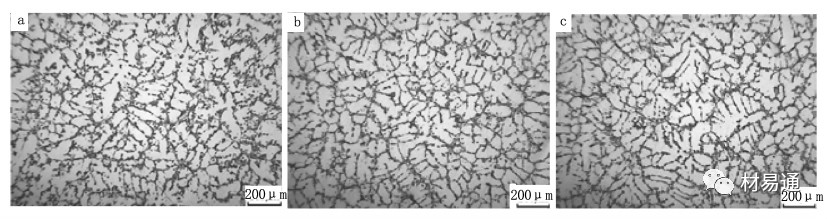

Fig. 2 Microstructure o nā alloys me nā mea'ē aʻe

A. Resorage he 0; b. Hou hou i 0.3%; c. Hou hou i 0.7%

Ma hope o ka hoʻohuiʻana i ka lewa o ka Honua i nā huaʻala o ka nui o nā mea e hiki ai i ka nui o ka lehulehu. a i ka wā e mālamaʻia ai ma keʻano kiʻekiʻe no kekahi manawa, e hoʻonui nuiʻia ka honua i keʻano o ka uila.

03 ʻO ka hopena o ka Microleaying o ka Honua

Loaʻa ka honua ma kahi o ka alumini a me nā alluinum a me nā hopena kūponoʻole i ka nui o ka papa'āina e hoʻoikaika ana i nā pūpū honua.

ʻO keʻano o keʻano o ka Honua o ka Honua i ka alumini a me alumini alloy e pili kokoke ana i kāna mau'āpana. ʻO ka maʻamau, i ka wā e emi ai nāʻikepili ma mua o 0.1%, he nui ka nui o nāʻano kīwī a me ka nui ʻIkeʻia nā mea hoʻohui, e hana i nā hopena uila e like me ka mea e hoʻoikaika ai.

◆ ◆ ◆ ◆ o ka hopena o ka Honua ma nā waiwai o ka alumini a me aluminum alloy ◆◆

01 Ka hopena o ka honua rare ma luna o nā mea nānā ponoʻole o ka alloy

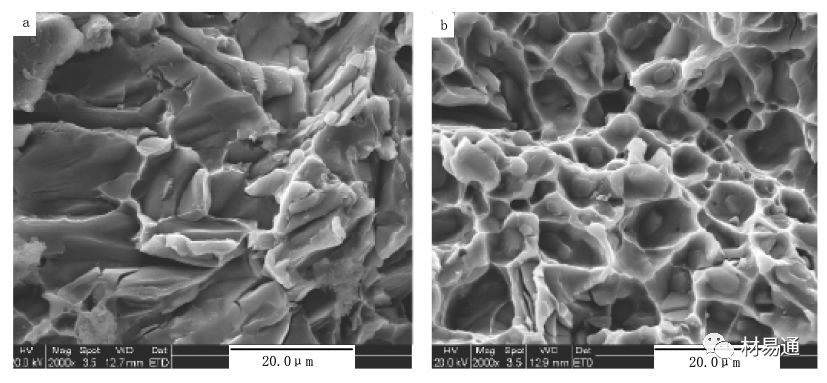

ʻO ka ikaika, paʻakikī, ellingation, e hoʻonui i ka paʻakikī, e hoʻopili i nā mea i hoʻopiliʻia e ka hoʻohuiʻana o ka alloy allot alum.bMai 205.9 MPA a 274 MPA, a me HB mai 80 a i ka 808; hoʻohui 0.42% sc a 7002bua nui mai 314mpa i 414mpa, σ0.2ua hoʻonuiʻia mai 282MPA a hiki i ka 378Mpa, ua hoʻonui nuiʻia ka waiwai mai 6.8% i ka 10.1 Hoʻohuiʻia 0.14% ~ 0.64% la i al-6mg-0.5mn alloy i hoʻonuiʻia e ka nui o ka alloy 3 e hōʻike ana i ka hiʻohiʻona sem o Tensile Fracture o Al-si7-MG0.8Alloy,ʻo ia ka mea e hōʻike ana he mea maʻamau keʻano brivage blelecle me kaʻole o ka manawa,ʻoiai e hōʻike anaʻo 0.3%,ʻoi aku ka paʻakikī.

Fig. 3 Tensile frachology morphology

A. ʻAʻole i hui pū me RU; B. Hoʻohui 0.3% re

02ʻO ka hopena o ka honua rare ma nā waiwai kiʻekiʻe o nā alloys

Ka hoʻohuiʻana i kekahi nui oka hiʻuʻonai loko o ka aluminum alloy hiki ke hoʻomaikaʻi maikaʻi i keʻano o keʻano o keʻano o ka alloy.alus. Hiki i nā CUS F C CU ALLYY E hoʻomaikaʻi i nā waiwai kiʻekiʻe o nā pono o nā alloys ma lalo3Kūpono i nā'āpana SC i maʻalahi i ke kāʻeiʻana i ka mahana kiʻekiʻe a me ke kauʻana me ka matrix, e hoʻomaikaʻi nui i keʻano kiʻekiʻe o ka alloy.

03 Ka hopena o ka Honua ma nā waiwai optical o nā alloys

Hoʻohui i ka honua rare i loko o ka aluluni alloy hiki ke hoʻololi i keʻano o ka first all all stream a me nā mea hou o ka alloy.12%.

04 Ka hopena o ka honua rare ma luna o nā waiwai uila o nā alloys

Hoʻohui maikaʻiʻia ka hoʻohuiʻana i ka alumini kiʻekiʻe-hoʻomaʻemaʻe i keʻano o ka alloy, akā hiki ke hoʻomaikaʻiʻia ka hopena o ka allutik Hiki i ka alloy ke hoʻomaikaʻi i keʻano o ka wā o ka alloy, i hanaʻia e ka nui o nā mea hana maʻamau I ka wā i hoʻohanaʻia ma nā huahana 25Kv, ua pālua ka helu koho, ua hōʻemiʻia ka nui o ka paul helu e 5%, a ua hōʻemi nui ka paona.

05Ka hopena o ka honua ralo ma luna o ka corrosion resistion of alloy

Ma kekahi mau lawelawe lawelawe i lawelaweʻia,ʻoi aku ka nui o nā mea hana crloride, nā loli o ka corrosion, crelice corrosion ʻIkeʻia e hoʻohui i ka nui o nā'āina'ē aʻe e hiki i nā alloys e hoʻonui i nā'āpana o nā mika Hōʻike ka hopena i ka hoʻohuiʻana i kahi liʻiliʻi o nā Honua Rare i keʻano o keʻano he 24% a me keʻano o ke aniani o 2024 alloy, e hana ana i ka electrode electroel a me keʻano o keʻano o ka antinu a me ke koʻikoʻi ke kū'ēʻana o nā mea hou,ʻo ia ka mea i hoʻohana nuiʻia e like me nā mea aerospace.

◆ ◆ kohoʻia mahana o ka lukuʻia allow Alula

Ua hoʻohuiʻia ka nui o ka honua ma keʻano o nā mea trace i nā mea a Alumini a me nā alloys'ē aʻe. He papaʻaina nui ka Honua, ua kiʻekiʻe kiʻekiʻe, kiʻekiʻe keʻano melpel, a maʻalahi hoʻi e maʻalahi a wela i nā kiʻekiʻe kiʻekiʻe. Ua hana kēia i kekahi mau pilikia i ka hoʻomākaukau a me ka noiʻana o ka holoʻana o ka alloys.ins e hoʻohana ana i keʻano o ka alloys.ins.

01 Ke kāwiliʻana i ke ala

ʻO ka hoʻololiʻana i ke ala menting i hoʻohuiʻia e hoʻohui i ka honua a iʻole i hui pūʻia i ka wai ma keʻano he alloy a me keʻano o keʻano o ka hana

02 Elepu

ʻO keʻano uila paʻakai paʻakaiʻo BlalTy i hoʻohuiʻia e hoʻohui i ka honua hoʻohuihui a me ka uila.Xalum i hanaʻia ma Kina. ʻO ka maʻamau, aiaʻelua mau ala,ʻo ka inoaʻo ka inoaʻo ka waiʻo ka wai a me ka eleuctoid etectivetionid. I kēia manawa, ua uluʻia e hoʻohuiʻia e nā hoʻohuihui honua e hiki ke hoʻohuiʻia i nā alloys electrolytic electrolid.

03 ʻO ke ala ho'ēmi a Alminothermic

No ka mea, he loli nui ka alumini, a hiki i keʻano o nāʻano likeʻole o ka'āina waena.

RE2O3+ 6EL → 2 ma2+ Al2O3

I waena o lākou,ʻo ka leleʻana o ka mika a iʻole ka mika ka nui o ka maʻi ma mua; ka ho'ēmiʻana i ka ho'ēmiʻana o Aluminothermic. Ma kahi haʻahaʻa haʻahaʻa (780 ℃), ua hoʻopauʻia ka hopena hoʻemiʻana o ka alminothermic i ka'ōnaehana o ka sodium a me ka sodium chloride i hanaʻia e ka mahana kiʻekiʻe.

◆ ◆ ◆ e holomua ana ka noi noiʻana o ka nui o ka honua alamacinmun anilos ◆ ◆ ◆ ◆ ◆

01 ʻO ka noiʻana o ka Rage Honua Alloy i loko o kaʻoihana mana

Ma muli o nā mea pono o ka hana maikaʻi, e lawe ana i ka mana kiʻekiʻe, e hoʻohana i ka corecondance ʻO kahiʻike kiʻekiʻe,ʻo ia kahi hopena nui loa i nā waiwai uila. Hiki i ka hoʻohuiʻana i kahi nui o ka honua e hiki ke hoʻomaikaʻi i ka model a me ka hoʻokaʻawaleʻana i ka honua a me nā mea ola maikaʻiʻole Ke kū'ē neiʻo Corrosionion i keʻano alloyum aluminum alloy. Hiki i nā kāpena a me nā mea hana i hanaʻia i ka Honua Holo Allonuainm alloy hiki ke hoʻonui i ka'āpana o nā māka cable a hoʻonui i ke ola o nā keiki.

02ʻO ka noiʻana o ka Rare Honua Alouminum Aly i kūkuluʻia

ʻO 6063 aluminum a Allonunumʻo ia ka nui loa i hoʻohana nuiʻia i loko o kaʻoihana kūkulu. Loaʻa ka hoʻohuiʻana o 0.15% ~ 0.25% ka honua, hiki i ka paeʻana, hoʻomālamalama a i loko, Hoʻohui a loaʻa paha i nā kolamu o nā kolamu e hoʻoponopono i nā hoʻokaʻawaleʻana o kaʻoihana, a iʻole ka nui o ka papaʻaina o ka alohilohi. ʻO ka laʻana, ua hoʻonuiʻia ka ikaika o kaʻaoʻao ma mua o 20%, ua hoʻonuiʻia ka waiwai o kaʻoihana e pili ana i ka 3%.

03Ka noiʻana o ka uila o ka honua aluminanum alloy i nā huahana o kēlā me kēia lā

Hoʻohui i nā'āpana o ka honua i ka honua maʻemaʻe a Al Mg Series a Alminum Plasty, aluminalum Uaʻoi aku ka nui o al mg repinglass ma mua o ka pā kaua o ka pānaʻi, he 12% paona nui, a ua hoʻonui nuiʻia ka hanaʻana o ka honua.

04 Ka noiʻana o ka uila o ka honua aluminanum aly i nā hiʻohiʻona'ē aʻe

Hoʻohui nui i kekahi mau tausani o ka Honua ma ka lehulehu i hoʻohana nuiʻia ma ka hanaʻo Al Si Sho hana e hiki ai i ka hana makloy. Ua hoʻohanaʻia nā mea kani he nui i nā mokulele, nā moku, nā kaʻa, nā kaʻa a me nā mea noiʻi a me nā mea noiʻi a me nā mea hana He ikaika ikaika loa ia, e hoʻoikaika ana i ka paleʻana, e hoʻomaikaʻi ana i ka ikaika, etc. o nā kaʻaahi, nā kaʻa kaʻa, nā kaʻa kaʻa, Etc.c55557Al mg Zr sc Sce scabitinit all i kūkuluʻia e Nasa i nā wahi mokulele a me ke kiʻekiʻe o ke aniani

Mai ka volume 33, e pili ana i ka 1 o ka honua rae e hele ai e Wang Hui, yang an a yun qi

Post Time: Jul-05-2023