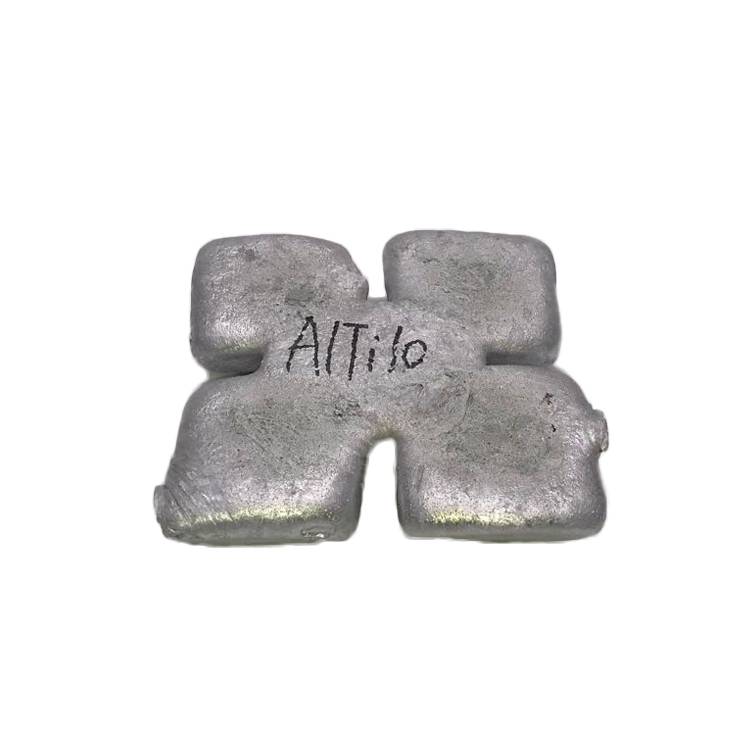

Alpi10 Ingot Txhuas Titanium Master alloy

Alti10 Ingot Aluminium Titanium Master Alloy

Cov tswv lag luam alloys yog cov khoom tiav ib nrab, thiab tuaj yeem tsim tau nyob rau hauv cov duab sib txawv. Lawv yog pre-aloyed sib xyaw ntawm alloying ntsiab. Lawv tseem yog lub npe hu ua hloov kho, tawv tawv, lossis cov xaim hluav taws xob los yog siv lawv cov ntawv thov. Lawv tau ntxiv rau ib tug yaj kom ua tiav cov txiaj ntsig. Lawv raug siv hloov cov hlau ntshiab vim tias lawv muaj kev lag luam thiab txuag lub zog thiab lub sijhawm ntau.

Khoom npe:Aluminium Titanium Master Alloy

Abbreviation:Al-TI Master Alloy

Lwm lub npe: Altanium Master alloy, Alsin Titanium Master Alloy, Alti Master Alloy

Cov ntsiab lus:ALTI10

Melting point: 1020-1070 ° C

Cov ntaub ntawv: slab, waffle, ingot, qog, thiab lwm yam

| Khoom npe | Aluminium Titaniumtus tswv alloy | ||||||||||||||||

| Lub hom phiaj | GB / T27677-2011 | ||||||||||||||||

| Zoo siab | Tshuaj lom neeg tshuaj lom neeg ≤% | ||||||||||||||||

| Seem | Si | Fe | Cu | Mn | Cr | Ni | Ti | B | V | Zn | Pb | Sn | Mg | C | Lwm Yam | Tag nrho cov impurities | |

| Naj ntawm3 | Al | 0.30 | 0.35 | / | / | / | / | 2.5 ~ 3.5 | / | / | / | / | / | / | / | 0.05 | 0.15 |

| Ntxiv ib | Al | 0.20 | 0.30 | / | / | / | / | 3.5 ~ 4.5 | / | / | 0.10 | / | / | / | / | 0.05 | 0.15 |

| Alti5 | Al | 0.50 | 0.45 | 0.15 | 0.35 | 0.10 | 0.10 | 4.5 ~ 5.5 | / | 0.25 | 0.15 | 0.10 | 0.10 | 0.50 | / | 0.05 | 0.15 |

| Alti6 | Al | 0.30 | 0.35 | / | / | / | / | 5.5 ~ 6.5 | 0.004 | 0.30 | / | / | / | / | / | 0.03 | 0.10 |

| ALTI10 | Al | 0.30 | 0.35 | / | / | / | 0.05 | 9.0 ~ 11.0 | 0.004 | 0.50 | / | / | / | / | / | 0.03 | 0.10 |

| Alti6a | Al | 0.20 | 0.20 | / | / | / | / | 5.5 ~ 6.5 | 0.004 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti10a | Al | 0.20 | 0.20 | / | / | / | 0.05 | 9.0 ~ 11.0 | 0.004 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Lub ntsiab 50012 | Al | 0.30 | 0.30 | / | / | 0.10 | 0.10 | 11.0 ~ 13.0 | / | 0.50 | / | / | 0.10 | / | / | 0.10 | 0.15 |

| Alti15 | Al | 0.30 | 0.30 | / | / | 0.15 | 0.15 | 14.0 ~ 16.0 | / | 0.50 | / | / | 0.15 | / | / | 0.10 | 0.15 |

| Alti3B1 | Al | 0.20 | 0.30 | / | / | / | / | 2.8 ~ 3.4 | 0.7 ~ 1.1 | / | / | / | / | / | / | 0.03 | 0.10 |

| Alti5B0.2 | Al | 0.30 | 0.35 | / | / | / | / | 4.5 ~ 5.5 | 0.15 ~ 0.25 | 0.25 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5B0.2a | Al | 0.15 | 0.20 | / | / | / | / | 4.5 ~ 5.5 | 0.15 ~ 0.25 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5B0.22b | Al | 0.30 | 0.40 | / | / | / | / | 4.5 ~ 5.5 | 0.1 ~ 0.5 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5B0.6a | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.5 ~ 0.7 | / | / | / | / | / | / | 0.03 | 0.10 |

| Alti5B0.6 | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.5 ~ 0.7 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5B1 | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.8 ~ 1.2 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5B1A | Al | 0.15 | 0.20 | / | / | / | / | 4.8 ~ 5.2 | 0.9 ~ 1.1 | 0.05 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5B1b | Al | 0.20 | 0.25 | / | / | / | / | 4.5 ~ 5.5 | 0.8 ~ 1.2 | 0.10 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5B1c | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.4 ~ 1.2 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| ALTI3C0.15A | Al | 0.20 | 0.20 | / | / | / | / | 2.6 ~ 3.4 | 0.004 | 0.05 | / | / | / | / | 0.08 ~ 0.22 | 0.03 | 0.10 |

| Alti3C0.15 | Al | 0.30 | 0.15 | / | / | / | / | 2.6 ~ 3.4 | 0.004 | 0.30 | / | / | / | / | 0.08 ~ 0.22 | 0.03 | 0.10 |

| Alti3C0.3 | Al | 0.20 | 0.20 | / | / | / | / | 2.6 ~ 3.4 | 0.004 | 0.05 | / | / | / | / | 0.25 ~ 0.35 | 0.03 | 0.10 |

| Cov Ntawv Thov | 1. Hardeners: Siv rau kev txhim kho lub cev thiab cov kws kho tshuab ntawm cov hlau alloys. 2. Cov khoom siv sib xyaw: siv rau kev tswj cov dispersion ntawm ib tug neeg muaju hauv cov hlau los ua cov qauv grain thiab ntau dua cov qauv grain qauv. 3. Modifiers & Cov Ntawv Tshwj Xeeb & Cov Ntawv Tshwj Xeeb: Feem ntau siv los nce lub zog, ductility thiab machinability. | ||||||||||||||||

| Lwm Cov Khoom | Almn,Alti,Alni,ALV,Tus ALSR,Alzr,Alca,Txhua tus,Ib alfe,Alcu, Alcr,Tus ALCL, Alre,Lub txim,Albi, Alas,Txiv ntoo, Alw,Alm, Alzn, alsn,Alce,ALY,Qos, APR, ALND, ALYB,Alsc, thiab lwm yam. | ||||||||||||||||

Daim ntawv muaj cai:

Dab tsi peb tuaj yeem muab tau: