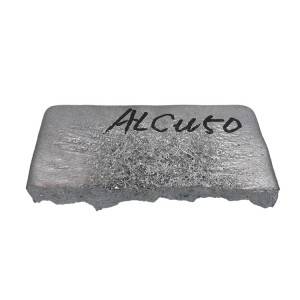

Tooj liab calcium cu-CA MUAB Alloy CCA20 Cuca30 ago Hlau

Tooj Cal calcium Master Alloy Tsob ntoo me Tsob ntoo 5Hlau egots

Tooj liab-calcium tswv alloyyog siv nyob rau hauv kev tsim ntau lawm ntawm cov khoom lag luam tooj liab. Tus tswv no tau ua los ntawm kev sib txuas tooj liab thiab calcium hauv cov kev sib piv (feem ntauTsob ntoo 5lossis Cuca30) kom ua tiav cov khoom xav tau thiab cov yam ntxwv xav tau rau ib daim ntawv thov tshwj xeeb.

Tooj liab alcium alloystau siv dav hauv kev tsim cov tooj liab thiab nws cov alloys vim lawv muaj peev xwm txhim kho cov khoom siv tshuab thiab cov khoom kawg ntawm cov khoom kawg. Nws yog qhov paub rau nws zoo deoxidation thiab desulffurization cov yam ntxwv, pab txhim kho cov khoom lag luam tooj liab zoo. Ib qho ntxiv, ntxiv cov calcium rau tooj liab ntxiv txhim kho nws cov cua sov thiab hluav taws xob conductivity, ua rau nws zoo tagnrho rau kev siv hluav taws xob thiab kev lag luam tsheb.

Ib qho ntawm qhov zoo ntawm kev siv atooj liab-calcium tswv alloyyog lub peev xwm los txo cov nqi ntau lawm. Los ntawm kev ntxiv tus tswv alloy rau tus tooj liab yaj, kev noj cov ntxhiab dawb thiab tooj liab tuaj yeem txo cov nqi hauv kev tsim khoom. Ib qho ntxiv, kev siv cov tswv alloys ua kom muaj kev tswj hwm ntau thiab cov khoom siv tsis sib xws hauv cov khoom kawg, yog li kev txhim kho sib xws thiab ua tau zoo.

Cov versatility ntawmtooj liab alcium alloysUa rau lawv haum rau ntau cov kev siv, suav nrog kev tsim cov xov hlau hluav taws xob, cov khoom siv tsheb kho tsheb thiab ntau yam khoom siv. Seb nws nce ntxiv lub zog thiab kav ntev ntawmTooj liab alloys los yog txhim kho lawv cov hluav taws xob conduction, qhov sib ntxiv ntawmtooj liab alcium alloysNqa ntau cov txiaj ntsig rau kev tsim khoom lag luam.

| Tooj Cal calcium Master Alloy | |||||||

| Zoo siab | Tsob ntoo 530 lossis customized | ||||||

| Cov Ntawv Thov | 1. Hardeners: Siv rau kev txhim kho lub cev thiab cov kws kho tshuab ntawm cov hlau alloys. 2. Cov khoom siv sib xyaw: siv rau kev tswj cov dispersion ntawm ib tug neeg muaju hauv cov hlau los ua cov qauv grain thiab ntau dua cov qauv grain qauv. 3. Modifiers & Cov Ntawv Tshwj Xeeb & Cov Ntawv Tshwj Xeeb: Feem ntau siv los nce lub zog, ductility thiab machinability. | ||||||

| Lwm Cov Khoom | Cub, cumg, Cusi, riam,Lub khob, Cuti, cuv, cuni,Lub kab mov, Cufe, Gecu,Cuas, Cua, Cuzr, CUHF, CUHF, Ntxwv, CULA,Kua nplaum, Cund, CUM, Cubi, thiab lwm yam. | ||||||