Alti10 ingot aluminum titanium master alloy

Alti10 Ingot Aluminum Titanium master Alloy

Ny tompo dia ny vokatra semi-pitsiny dia azo avy amin'ny endrika samihafa. Mifangaro ny singa allaogy mialoha azy ireo. Izy ireo ihany koa dia antsoina hoe modifiers, mpikatroka, na refinetra voan'ny varimbazaha mifototra amin'ny fampiharana azy ireo. Ampiana amin'ny kibo izy ireo mba hahatratrarana ny vokatra tena ilaina. Izy ireo dia ampiasaina fa tsy metaly madio satria tena toekarena sy mahavonjy ny angovo sy ny famokarana.

Anaran'ny vokatra:Aluminum Titanium master Alloy

Fanafohezana:Al-ti master alloy

Anarana hafa: aluminium master alloy, aluminium titanium master alloy, alti master alloy

Content:Alti10

Mangatsiatsiaka: 1020-1070 ° C

Fomba: slab, waffle, ingot, lumps, sns

| Anaran'ny vokatra | Aluminium titaniummaster alloy | ||||||||||||||||

| Malagasy | GB / t2767717-2011 | ||||||||||||||||

| Votoatiny | Compositions simika ≤% | ||||||||||||||||

| Mila mahay mandanjalanja | Si | Fe | Cu | Mn | Cr | Ni | Ti | B | V | Zn | Pb | Sn | Mg | C | Olon-tokana hafa | Ny fahalotoana tanteraka | |

| Alti3 | Al | 0.30 | 0.35 | / | / | / | / | 2.5 ~ 3.5 | / | / | / | / | / | / | / | 0.05 | 0.15 |

| Alti4 | Al | 0.20 | 0.30 | / | / | / | / | 3.5 ~ 4.5 | / | / | 0.10 | / | / | / | / | 0.05 | 0.15 |

| Alti5 | Al | 0.50 | 0.45 | 0.15 | 0.35 | 0.10 | 0.10 | 4.5 ~ 5.5 | / | 0.25 | 0.15 | 0.10 | 0.10 | 0.50 | / | 0.05 | 0.15 |

| Alti6 | Al | 0.30 | 0.35 | / | / | / | / | 5.5 ~ 6.5 | 0.004 | 0.30 | / | / | / | / | / | 0.03 | 0.10 |

| Alti10 | Al | 0.30 | 0.35 | / | / | / | 0.05 | 9.0 ~ 11.0 | 0.004 | 0.50 | / | / | / | / | / | 0.03 | 0.10 |

| Alti6a | Al | 0.20 | 0.20 | / | / | / | / | 5.5 ~ 6.5 | 0.004 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti10a | Al | 0.20 | 0.20 | / | / | / | 0.05 | 9.0 ~ 11.0 | 0.004 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti12 | Al | 0.30 | 0.30 | / | / | 0.10 | 0.10 | 11.0 ~ 13.0 | / | 0.50 | / | / | 0.10 | / | / | 0.10 | 0.15 |

| Alti15 | Al | 0.30 | 0.30 | / | / | 0.15 | 0.15 | 14.0 ~ 16.0 | / | 0.50 | / | / | 0.15 | / | / | 0.10 | 0.15 |

| Alti3b1 | Al | 0.20 | 0.30 | / | / | / | / | 2.8 ~4 | 0.7 ~ 1.1 | / | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.2 | Al | 0.30 | 0.35 | / | / | / | / | 4.5 ~ 5.5 | 0.15 ~ 0.25 | 0.25 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.2a | Al | 0.15 | 0.20 | / | / | / | / | 4.5 ~ 5.5 | 0.15 ~ 0.25 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.2b | Al | 0.30 | 0.40 | / | / | / | / | 4.5 ~ 5.5 | 0.1 ~ 0.5 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.6a | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.5 ~ 0.7 | / | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.6 | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.5 ~ 0.7 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b1 | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.8 ~ 1.2 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b1a | Al | 0.15 | 0.20 | / | / | / | / | 4.8 ~ 5.2 | 0.9 ~ 1.1 | 0.05 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b1b | Al | 0.20 | 0.25 | / | / | / | / | 4.5 ~ 5.5 | 0.8 ~ 1.2 | 0.10 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b1c | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.4 ~ 1.2 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti3c0.15a | Al | 0.20 | 0.20 | / | / | / | / | 2.6 ~ 3.4 | 0.004 | 0.05 | / | / | / | / | 0.08 ~ 0.22 | 0.03 | 0.10 |

| Alti3c0.15 | Al | 0.30 | 0.15 | / | / | / | / | 2.6 ~ 3.4 | 0.004 | 0.30 | / | / | / | / | 0.08 ~ 0.22 | 0.03 | 0.10 |

| Alti3c0.3 | Al | 0.20 | 0.20 | / | / | / | / | 2.6 ~ 3.4 | 0.004 | 0.05 | / | / | / | / | 0.25 ~ 0.35 | 0.03 | 0.10 |

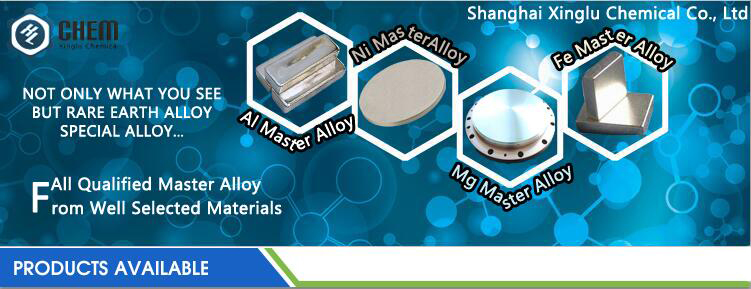

| Rindranasa | 1. Hardeners: ampiasaina amin'ny fanatsarana ny fananana ara-batana sy mekanika amin'ny alloys metaly. 2. Ny refinetra varimbazaha: nampiasaina tamin'ny fifehezana ny fanaparitahana kristaly tsirairay ao amin'ny metaly mba hamokatra firafitra voam-bary tsara sy mihoatra. 3. Modifiers & Alloys manokana: Matetika ampiasaina hampitombo ny tanjaka, ny doka ary ny fanamaivanana. | ||||||||||||||||

| Vokatra hafa | ALMN,Alti,Alni,Alv,Alsr,Alzr,Alca,allí,Alfe,Alcu, Alcr,ALB, Alre,Albe,Albi, Allo,Almo, ALW,Almg, Alzn, alsn,Alce,Aly,Alla, Alpr, alnd, alyb,Alsc, sns | ||||||||||||||||

Certificate:

Inona no azontsika omena: