Rare earth elements are widely used in defense, military industry, aviation, aerospace and other military fields due to their irreplaceable optical, electrical, magnetic and thermal properties. Rare earth metals and alloy materials are used in weapons rare earth steel and weapon warhead materials; rare earth permanent magnet motors are used in aviation and aerospace components; rare earth giant magnetostrictive materials are used in ship sonars; rare earth optical materials are used in tanks and lasers; rare earth superconducting materials are used in electromagnetic guns and combat systems, etc., which are of great strategic significance. The application and development of new rare earth materials in the military field has become an important research direction. Relying on the technical resource advantages of the rare earth industry to develop civilian-military industries will not only increase the added value of rare earth products, but also help enhance national defense capabilities.

Innovation highlights

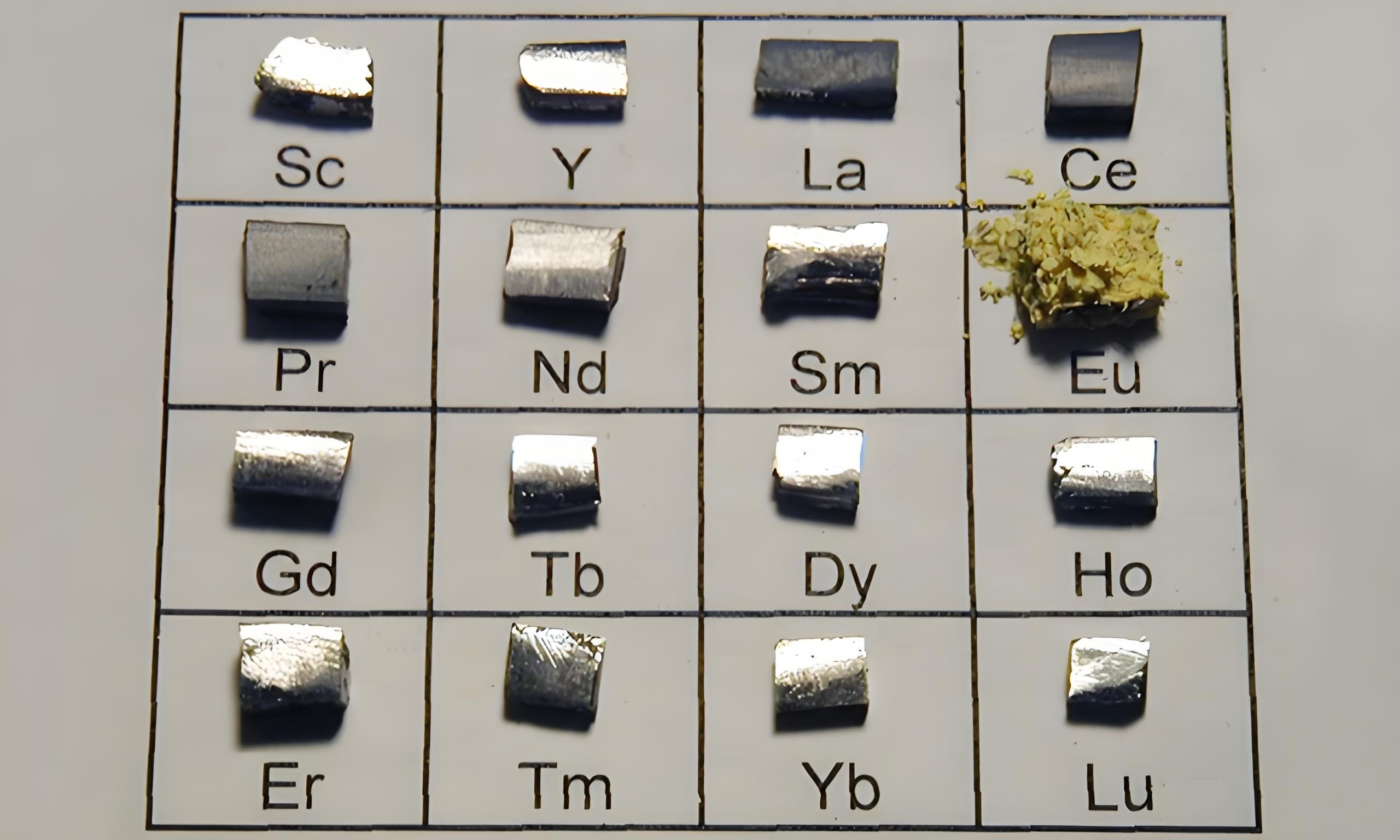

17 rare earth elements, including lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, scandium, and yttrium, and their compounds and materials have irreplaceable optical, electrical, magnetic, and thermal properties. They are called "vitamins of new materials" and are listed by the state as strategic resources and key elements for the development of high-tech. They are indispensable strategic resources for countries around the world to transform traditional industries, develop high-tech and cutting-edge defense technologies. They directly affect the development speed of high-tech industries such as optical instruments, electronics, aviation, aerospace, weapons, ships, missiles, and nuclear industries. and level, greatly promoted the development of modern military technology, and became one of the decisive factors for victory in modern wars, such as the Gulf War and the Iraq War. The US "Defense News" also introduced its military use. For example, the guidance device of the "Tomahawk" cruise missile, the aiming system of the MIA2 tank, and the high-heat-resistant engine of the jet fighter all require rare earths. With the development of the information warfare model, military experts around the world are paying close attention to the military application of rare earths and their compounds. This article summarizes and organizes the application of new rare earth materials in modern military technology.

Research review

The effects of rare earth on steel include purification and alloying, namely desulfurization, deoxidation, degassing, eliminating the influence of low-melting point harmful impurities, refining grains and organization, affecting the phase transition point of steel, thereby improving the hardenability and mechanical properties of steel, etc. The addition methods include punching method, wire feeding method (cored wire or rare earth metal wire, rod), hanging method, blowing method and electroslag remelting method. Research on rare earth steel for weapons 601, 602 armor steel in 1962, 623 cast armor steel in 1975, and the current 685 armor steel (30MnCrNiMo) have been used in succession. Rare earth materials suitable for weapons have been developed, such as rare earth special steel, pure rare earth metal, composite rare earth metal, etc. The application of rare earth steel in the field of weapons is increasing year by year.

1 Weapon Rare Earth Steel The 601 and 602 armored steels in 1962, the 623 cast armored steel in 1975, and the current 685 armored steel (30MnCrNiMo) have been successively used in tanks such as 59 and M1A1, making their anti-strike capabilities nearly doubled compared to carbon steel. From 701 and 703 nickel-free gun steels to today's ultra-high boring pressure-resistant RECrMoV steel, the comprehensive strength index of the new process is more than 100 times that of ordinary steel pipes of the same specification, and less than 5 countries can independently manufacture large-caliber tank guns. 0.05% of rare earth is added to carbon steel to make S20ARE cartridge steel. This rare earth steel has a lateral impact value of about 70% to 100% higher than that of the original carbon steel, and the impact value at -40°C is nearly doubled. Experiments have proved that it meets tactical and technical requirements and realizes the replacement of copper with steel in cartridge materials. In addition, the use of rare earth steel in tank track plates, tail fins of high-speed armor-piercing discarding sabot projectiles, muzzle brakes and artillery structural parts reduces the processing steps, improves the utilization rate of steel, and meets tactical and technical requirements.

2 Rare earth metals for warheads Since my country has adopted rare earth ductile iron (rare earth ferrosilicon alloy containing cerium) as the material for muzzle-loading projectiles to manufacture mortar shells of various calibers, the mechanical properties of the shells have been improved by 1 to 2 times, the number of effective killing fragments has doubled, and the lethality has been greatly improved. Mortar body materials, cannon shells and field rocket shells also use rare earth ductile iron, and the number of effective killing fragments and the intensive killing radius are higher than those of steel shells. The introduction of rare earth materials has solved the bottleneck problem that once constrained the development of muzzle-loading projectiles.

Lanthanum, cerium, praseodymium, neodymium, samarium and yttrium have very low ignition points, cerium: 160℃, praseodymium: 290℃, neodymium: 270℃, and release a lot of heat when burning. For example, the combustion heat of cerium is only 7.2MJ/g, but the unit volume combustion heat is as high as 39~54kJ/cm3. The US Mark-82 227kg bomb uses a rare earth metal lining, which not only has an explosive killing effect, but also produces an incendiary effect. The air-to-ground "Damper" rocket warhead is equipped with 108 rare earth metal square rods as lining, replacing some prefabricated fragments. Static explosion tests have shown that its ability to ignite aviation fuel is 44% higher than that of a vessel without a lining.

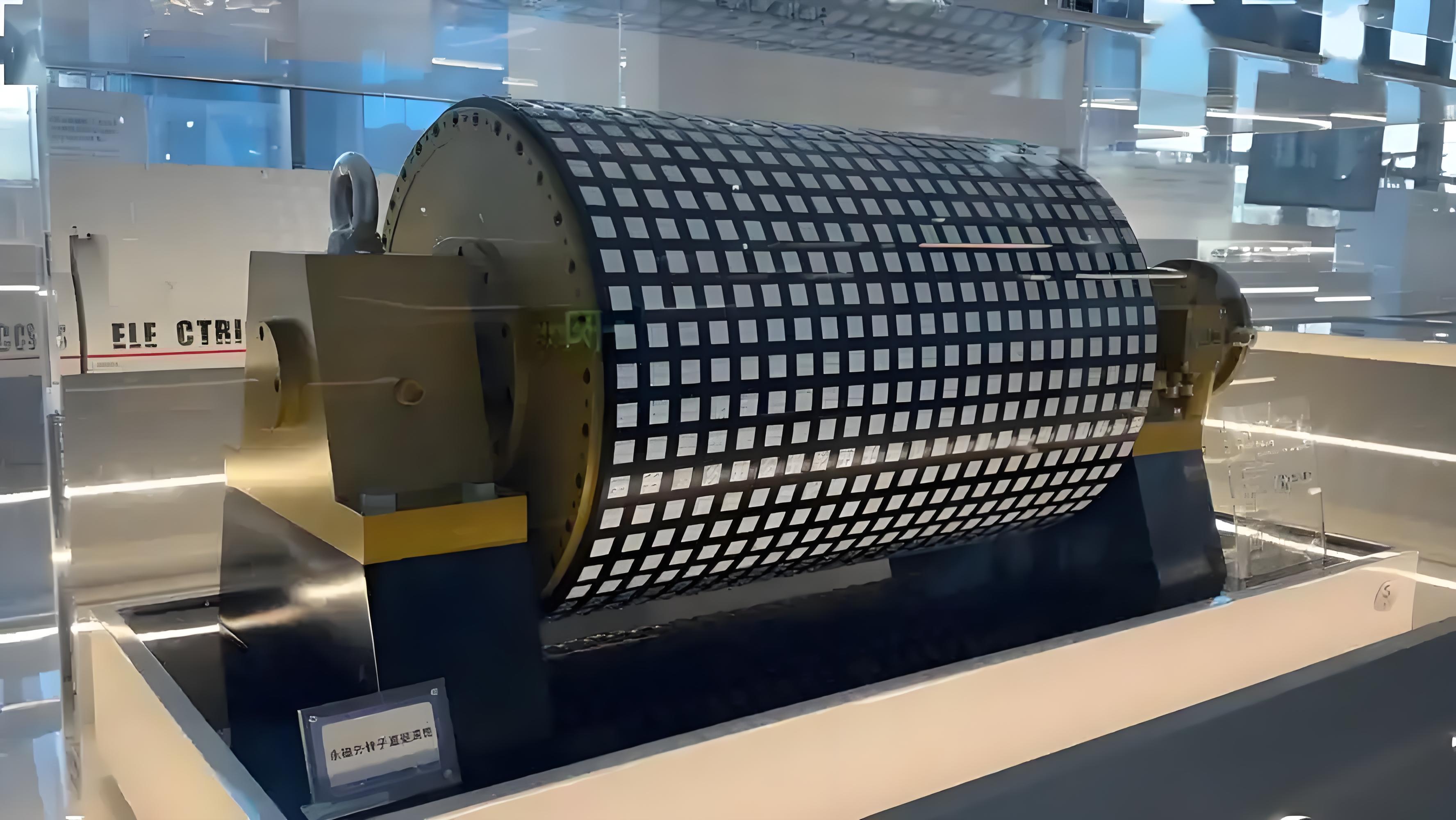

3 Rare earth permanent magnet materials for aerospace Rare earth permanent magnets include rare earth cobalt (Sm-Co series) and neodymium iron boron (NdFe-B series), which are called "high-performance permanent magnet materials". They have the characteristics of "three highs" of remanence (Br), coercive force (Hc) and maximum magnetic energy product ([BH) max], which is more than 100 times higher than the magnetic properties of magnetic steel in the 1970s. SmCo5 and Sm2Co17 permanent magnet materials have better thermal stability than neodymium iron boron permanent magnet materials.

Rare earth permanent magnet materials can achieve high performance, small size and light weight of power electronic components and complete machines. Various types of motors have been developed, such as DC torque motors, DC generators, variable speed constant frequency starting engines, excitation commutator motors, high-frequency large motors, servo motors, micro motors, synchronous motors, etc.

These products have become important components in modern military.

Future Development

(1) Rare earth metals, alloys, permanent magnetic materials, magnetostrictive materials, optical materials, superconducting materials, etc. formed by 17 rare earth elements have been applied to weapons rare earth steel, weapon warheads, aerospace components, ship sonar, tanks and lasers, electromagnetic guns, combat systems, nuclear shielding materials, etc., which are of great strategic significance.

(2) The military industry has become an important field of downstream application of the rare earth industry. The company where the author works has been engaged in rare earth separation for many years and has developed products such as cerium slag for the manufacture of rare earth ferrosilicon alloys, single rare earth compounds for smelting rare earth metal rods, and high-energy additives for solid propellants. Relying on the technical resource advantages of the rare earth industry to develop civilian-military industry, it not only increases the added value of rare earth products, but also helps to enhance the national defense capabilities.

To get rare earth raw material free sample or for more information welcome to contact us

Sales@shxlchem.com; Delia@shxlchem.com

Whatsapp& tel :008613524231522; 0086 13661632459

Post time: Feb-07-2025