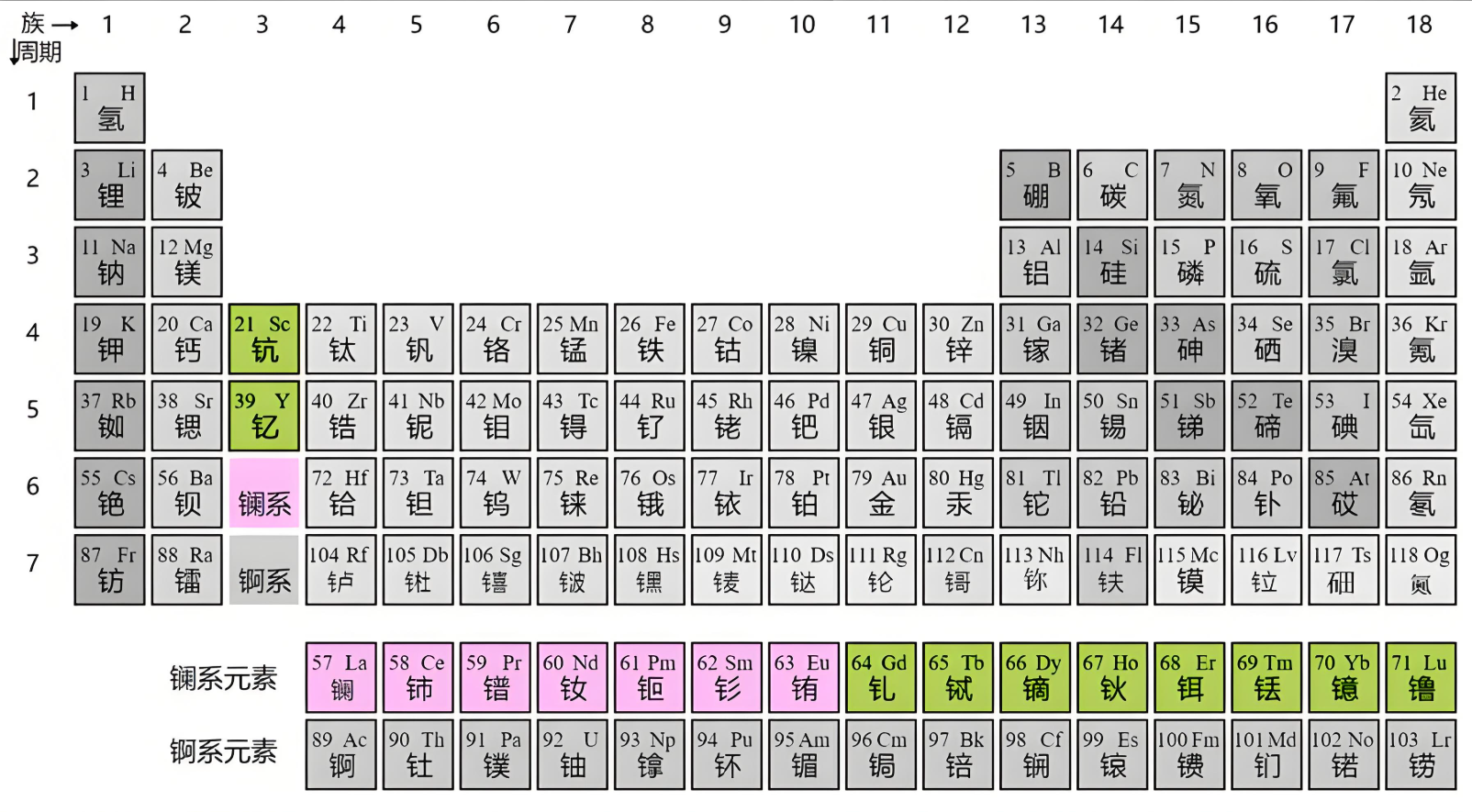

Rare earth elements are a general term for 17 metal elements, including 15 lanthanide elements and scandium and yttrium. Since the end of the 18th century, they have been widely used in metallurgy, ceramics, glass, petrochemicals, printing and dyeing, agriculture and forestry and other industries. The application of rare earth elements in my country's ceramic industry began in the 1930s. In the 1970s, the total amount of rare earths used in ceramic materials reached 70t/year, accounting for about 2% to 3% of the total domestic production. At present, rare earths are mainly used in structural ceramics, functional ceramics, ceramic glazes and other fields. With the continuous development and application of new rare earth materials, rare earths are used as additives, stabilizers and sintering aids in various ceramic materials, which greatly improves their performance, reduces production costs, and makes their industrial application possible.

Rare earth elements are a general term for 17 metal elements, including 15 lanthanide elements and scandium and yttrium. Since the end of the 18th century, they have been widely used in metallurgy, ceramics, glass, petrochemicals, printing and dyeing, agriculture and forestry and other industries. The application of rare earth elements in my country's ceramic industry began in the 1930s. In the 1970s, the total amount of rare earths used in ceramic materials reached 70t/year, accounting for about 2% to 3% of the total domestic production. At present, rare earths are mainly used in structural ceramics, functional ceramics, ceramic glazes and other fields. With the continuous development and application of new rare earth materials, rare earths are used as additives, stabilizers and sintering aids in various ceramic materials, which greatly improves their performance, reduces production costs, and makes their industrial application possible.

Application of rare earth elements in structural ceramics

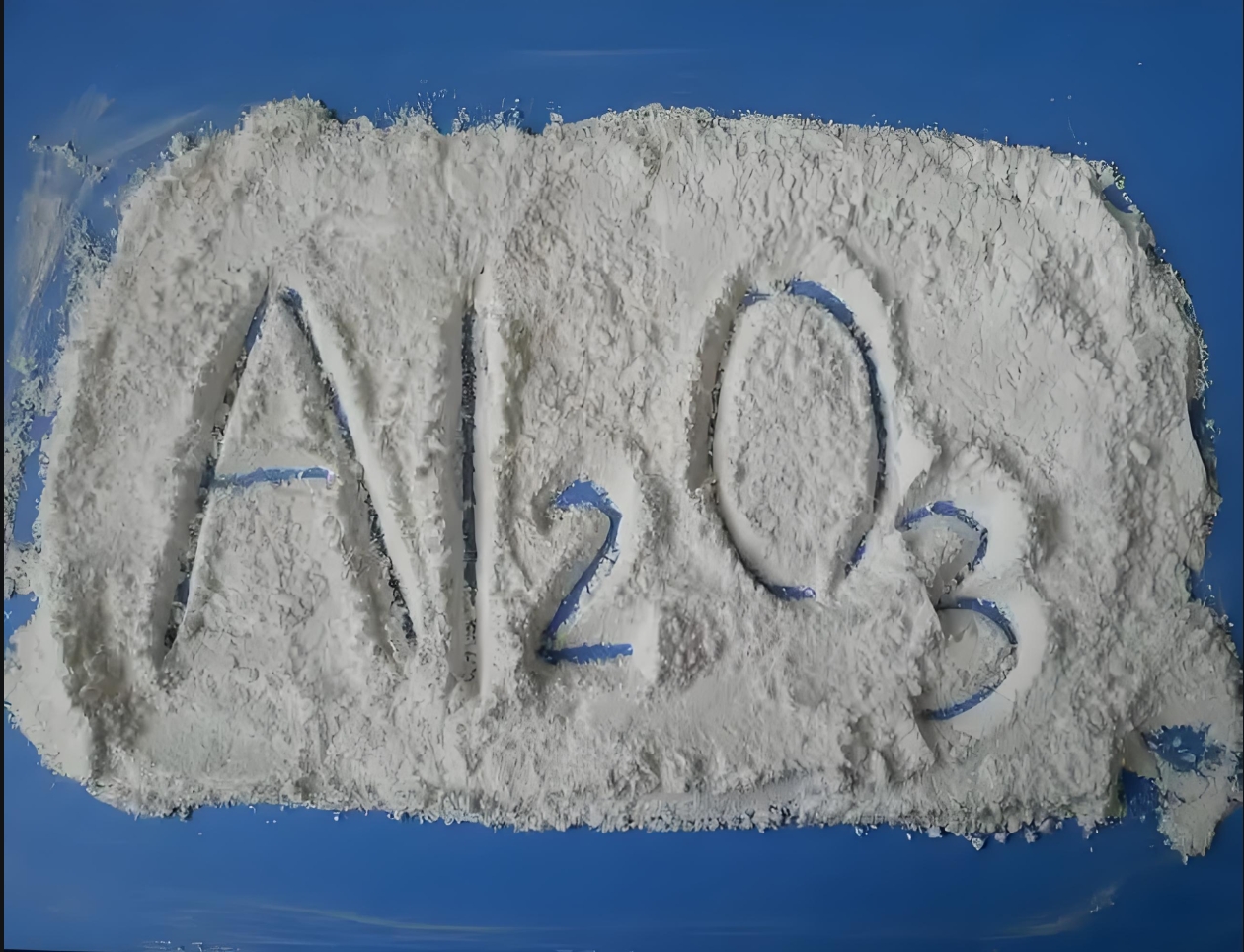

■ Application in Al2O3 ceramics Al2O3 ceramics are the most widely used structural ceramics due to their high strength, high temperature resistance, good insulation, wear resistance, corrosion resistance, and good electromechanical properties. Adding rare earth oxides such as Y2O3, La2O3, Sm2O3, etc. can improve the wetting properties of Al2O3 composite materials, reduce the melting point of ceramic materials; reduce the porosity of the material and increase the density; hinder the migration of other ions, reduce the migration rate of grain boundaries, inhibit grain growth, and facilitate the formation of dense structures; improve the strength of the glass phase, thereby achieving the purpose of improving the mechanical properties of Al2O3 ceramics.

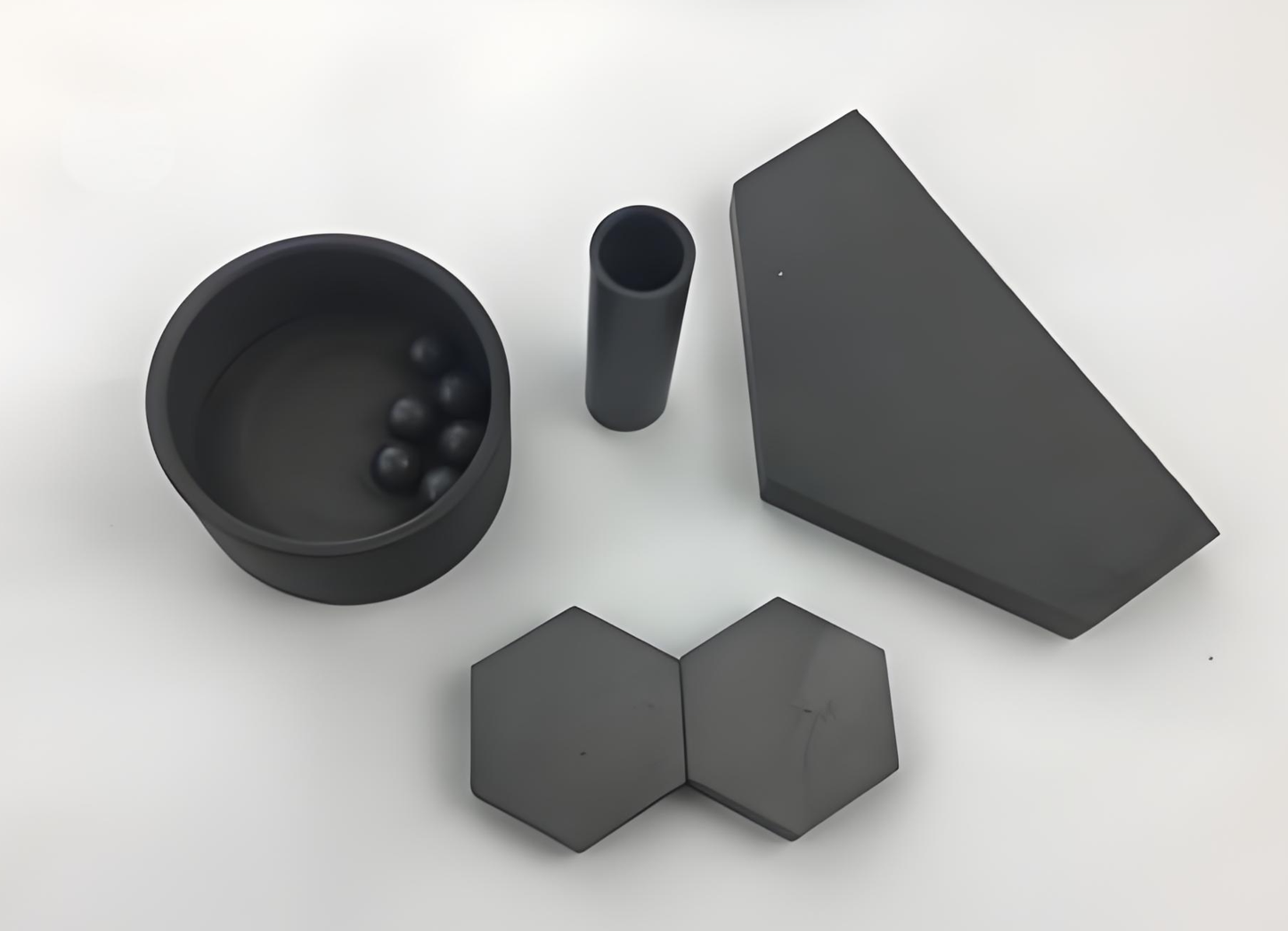

■ Application in Si3N4 ceramicsSi3N4 ceramics have excellent mechanical properties, thermal properties and chemical stability, and are the most promising materials for high-temperature structural ceramics. Since Si3N4 is a strong covalent bond compound, pure Si3N4 cannot be densified by conventional solid phase sintering. Therefore, in addition to the reaction sintering of direct nitridation of Si powder, a certain amount of sintering aid must be added to make a dense material. At present, the more ideal sintering aids for preparing Si3N4 ceramics are rare earth oxides such as Y2O3, Nd2O3, and La2O3. On the one hand, these rare earth oxides react with trace SiO2 on the surface of Si3N4 powder at high temperature to generate nitrogen-containing high-temperature glass phases, which effectively promote the sintering of Si3N4 ceramics; on the other hand, they form Y-La-Si-O-N glass grain boundaries with high refractoriness and viscosity, have high high-temperature flexural strength and good oxidation resistance, and are easy to precipitate crystalline compounds containing Y and La with high melting points under high temperature conditions, which improves the high-temperature fracture toughness of the material.

■ Application in ZrO2 ceramics ZrO2 ceramics have high density, high melting point and hardness, especially high bending strength and fracture toughness, which are the highest among all ceramics. Since the crystal transformation of ZrO2 is accompanied by obvious volume change, the scope of direct use is limited. With the deepening of research work, it is found that the addition of rare earth oxides has a better inhibitory and stabilizing effect on the phase change of ZrO2. Commonly used rare earth oxides are mainly Y2O3, Nd2O3, and Ce2O3. Their ionic radius is basically close to that of Zr4+, and they can form monoclinic, tetragonal and cubic substitutional solid solutions with ZrO2. This type of ZrO2 ceramic material has good technical performance indicators. For example, CeO2 can form a phase region of tetragonal zirconia solid solution in a wide range with ZrO2, which is a good solid electrolyte material. Y2O3-stabilized ZrO2 (YSZ) is an excellent oxygen ion conductor material, which has been widely used in solid oxide fuel cells (SOFC), oxygen sensors, and methane partial oxidation membrane reactors.

■ Application in SiC ceramics Silicon carbide ceramics are resistant to high temperatures, thermal shock, corrosion, wear, good thermal conductivity and light weight, and are commonly used high-temperature structural ceramics. The strong covalent bonding characteristics of SiC determine that it is difficult to achieve sintering densification under normal conditions. It is usually necessary to add sintering aids or use hot pressing and hot isostatic pressing sintering processes. The production process is complicated and the cost is high. The most effective sintering aid for pressureless sintering of SiC is Al2O3-Y2O3; SiC-YAG ceramic composite materials with Y3Al5O12 (YAG for short) as the main sintering aid can achieve densification sintering at a lower temperature, so they are considered to be one of the most promising silicon carbide ceramic systems.

■ Application in AlN ceramics AlN is a covalent bond compound with a high melting point, high thermal conductivity, low dielectric constant, and resistance to the corrosion of metals and alloys such as iron and aluminum. It has excellent high temperature resistance in special atmospheres and is an ideal large-scale integrated circuit substrate and packaging material. Since AlN is a covalent bond, sintering is very difficult, and a single sintering aid can only reduce the sintering temperature to a limited extent, so composite aids (rare earth metal oxides and alkaline earth metal oxides) are usually used as sintering aids to form a liquid phase to promote sintering. In addition, sintering aids can also react with oxygen impurities in AlN, reduce aluminum vacancies caused by partial oxygen dissolving into the AlN lattice, and improve the thermal conductivity of AlN.

■ Application in Sialon ceramics Sialon ceramics are a kind of Si-N-O-Al dense polycrystalline nitride ceramics developed on the basis of Si3N4 ceramics. They are formed by partial replacement of Si atoms and N atoms in Si3N4 by Al atoms and O atoms in Al2O3. Their strength, toughness, and oxidation resistance are better than Si3N4 ceramics, and they are particularly suitable for ceramic engine components and other wear-resistant ceramic products. Sialon materials are not easy to sinter. The introduction of rare earth oxides is conducive to the formation of liquid phase at a lower temperature, which effectively promotes sintering. At the same time, rare earth cations can enter the lattice of the α-Si3N4 phase, reduce the content of the glass phase and form a grain boundary phase, improving the room temperature and high temperature performance of the material. Studies have shown that adding 1% Y2O3 can form a high-temperature glass phase when sintering Sialon ceramics at high temperatures, which not only promotes sintering, but also improves its fracture toughness. In addition, adding a small amount of Y2O3 also greatly improves its oxidation resistance.

Application of rare earth elements in functional ceramics

Rare earths are closely related to functional ceramics. Adding certain rare earth elements to the raw materials of many functional ceramics can not only improve the sintering, density, strength, etc. of the ceramics, but more importantly, it can significantly improve their unique functional effects.

1 Role in superconducting ceramics Since 1987, when material scientists from China, Japan, the United States and other countries discovered that oxide ceramics yttrium barium copper oxide (YBCO) have excellent high-temperature superconductivity (Tc up to 92K), people have done a lot of work in the performance research and application development of rare earth high-temperature superconducting ceramics, and have made many major progress. Japanese studies have shown that after replacing Y in YBCO with light rare earths (Ln) such as Nd, Sm, Eu, and Gd, the critical magnetic field strength of the resulting superconducting ceramic material LnBCO is significantly improved, and the magnetic flux pinning force is also greatly enhanced, which is of great practical value in electricity, energy storage and transportation. Peking University used ZrO2 as a substrate and heated it to about 200°C, and evaporated Y (or other rare earths), Ba oxides and Cu on the substrate in layers for diffusion treatment, and heat treated them in the temperature range of 800-900°C. The resulting superconducting ceramics showed good metallic resistance temperature coefficient above 100K. Kagoshima University in Japan added rare earth La to Sr and Nb oxides to make a ceramic film, which exhibited superconductivity at 255K.

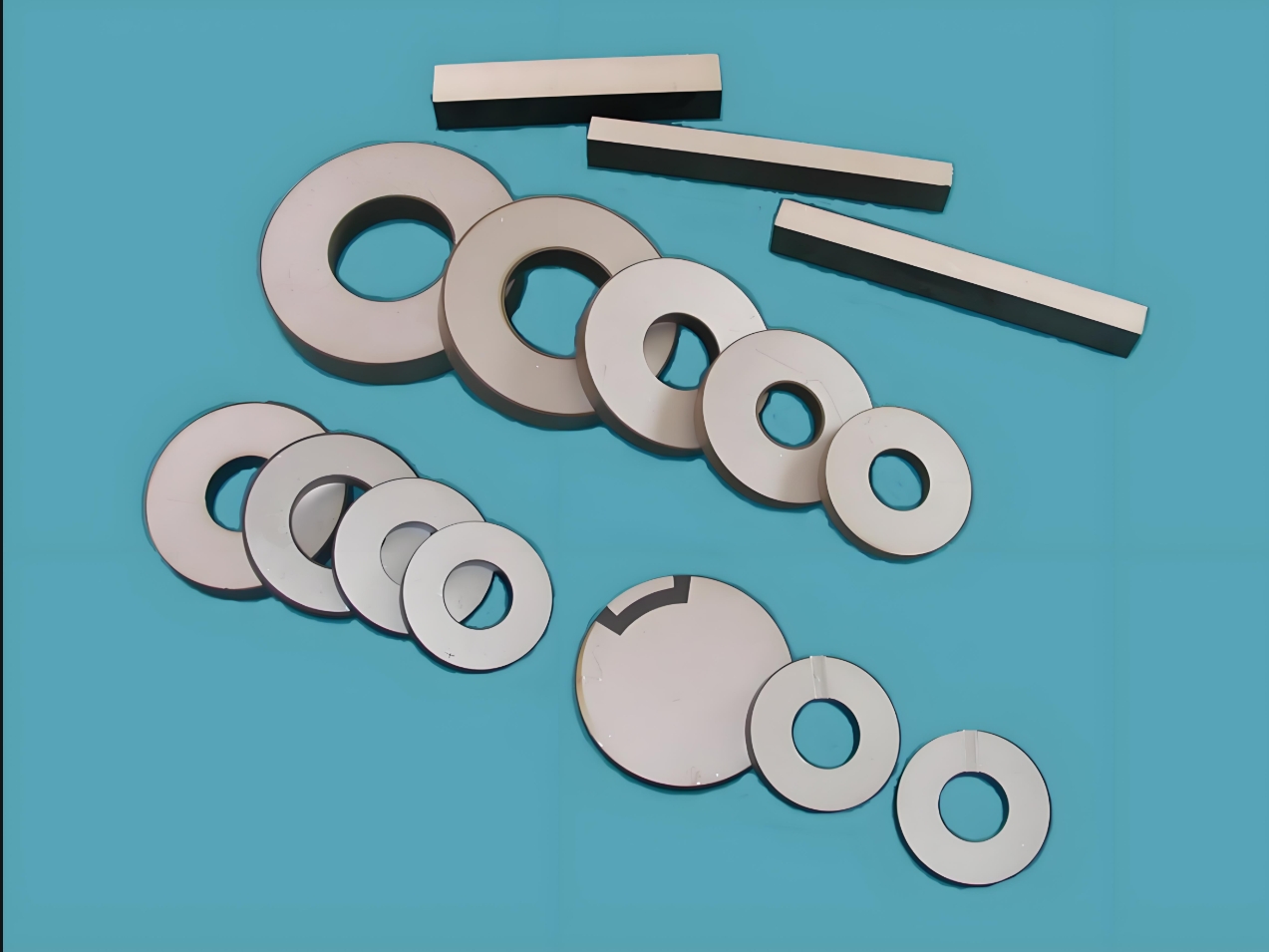

2 Application in piezoelectric ceramics Lead titanate (PbTiO3) is a typical piezoelectric ceramic with mechanical energy-electric energy coupling effect. It has a high Curie temperature (490°C) and a low dielectric constant, and is suitable for application under high temperature and high frequency conditions. However, during its preparation and cooling process, micro cracks are prone to occur due to the cubic-tetragonal phase transition. In order to solve this problem, rare earths are used to modify it. After sintering at 1150°C, RE-PbTiO3 ceramics with a relative density of 99% can be obtained. The microstructure is significantly improved and can be used to manufacture transducer arrays working under high frequency conditions of 75MHZ. In lead zirconate titanate (PZT) piezoelectric ceramics with high piezoelectric coefficients, by adding rare earth oxides such as La2O3, Sm2O3, and Nd2O3, the sintering properties of PZT ceramics can be significantly improved and stable electrical and piezoelectric properties can be obtained. In addition, the performance of PZT ceramics can be improved by adding a small amount of rare earth oxide CeO2. After adding CeO2, the volume resistivity of PZT ceramics increases, which is conducive to the realization of polarization under high temperature and high electric field in the process, and its resistance to time aging and temperature aging are also improved. PZT ceramics modified by rare earths have been widely used in high-voltage generators, ultrasonic generators, underwater acoustic transducers and other devices.

3 Application in Conductive Ceramics Yttrium-stabilized zirconia (YSZ) ceramics with rare earth oxide Y2O3 as additive have good thermal and chemical stability at high temperatures, are good oxygen ion conductors, and have a prominent position in ion conductive ceramics. YSZ ceramic sensors have been successfully used to measure the oxygen partial pressure in automobile exhaust, effectively control the air/fuel ratio, and have significant energy-saving effects. They have been widely used in industrial boilers, smelting furnaces, incinerators and other combustion-based equipment. However, YSZ ceramics only show high ionic conductivity when the temperature is higher than 900°C, so their application is still subject to certain restrictions. Existing research has found that adding an appropriate amount of Y2O3 or Gd2O3 to Bi2O3 ceramics with higher ionic conductivity can stabilize the Bi2O3 face-centered cubic phase to room temperature. At the same time, X-ray diffraction patterns have also shown that (Bi2O3)0.75·(Y2O3)0.25 and (Bi2O3)0.65·(Gd2O3)0.35 are both stable face-centered cubic structures with high oxygen ion conductivity. After coating the side of this ceramic with a protective film of (ZrO2)0.92(Y2O3)0.08, fuel cells and oxygen sensors with high ionic conductivity and good stability that can work under medium temperature conditions (500~800℃) can be prepared and assembled, which is conducive to solving the difficulties brought about by high-temperature technology.

4 Application in dielectric ceramics Dielectric ceramics are mainly used to make ceramic capacitors and microwave dielectric components. In dielectric ceramics such as TiO2, MgTiO3, BaTiO3 and their composite dielectric ceramics, adding rare earths such as La, Nd, and Dy can significantly improve their dielectric properties. For example, in BaTiO3 ceramics with a high dielectric constant, adding La and Nd rare earth compounds with a dielectric constant value of ε=30~60 can keep its dielectric constant stable over a wide temperature range, and the service life of the device is significantly improved. In dielectric ceramics for thermal compensation capacitors, rare earths can also be appropriately added as needed to improve or adjust the dielectric constant, temperature coefficient, and quality factor of ceramics, thereby expanding its application range. The thermally stable capacitor magnesium titanate ceramics are modified with La2O3, and the obtained MgO·TiO2-La2O3-TiO2 ceramics and CaTiO3-MgTiO3-La2TiO5 ceramics not only maintain the original characteristics of low dielectric loss and temperature coefficient, but also significantly improve their dielectric constant.

5 Application in sensitive ceramics Sensitive ceramics are an important type of functional ceramics. They are characterized by being sensitive to certain external conditions such as voltage, gas composition, temperature, humidity, etc. Therefore, they can monitor circuits, operating processes or environments through the reaction or change of their related electrical performance parameters. They are widely used as sensing elements in control circuits, so they are also called sensor ceramics. There is a close relationship between rare earths and the performance of this type of ceramics.

(1) Electro-optical ceramics: By adding rare earth oxide La2O3 to PZT, transparent lead lanthanum zirconate titanate (PLZT) electro-optical ceramics can be obtained. The original matrix material PZT is generally opaque due to the presence of pores, grain boundary phases and anisotropy, while the addition of La2O3 makes its microstructure uniform, largely eliminates pores, weakens its anisotropy, and significantly reduces the light scattering caused by multiple refractions on the grain boundaries and the light scattering caused by the second phase. Therefore, PLZT has good light transmission performance. PLZT is widely used in goggles for shielding nuclear explosion radiation, windows of heavy bombers, optical communication modulators, holographic recording devices, etc.

(2) Varistor ceramics: Central South University of Technology studied the effect of rare earth elements on the electrical properties of ZnO varistor ceramics. After ZnO varistor ceramics were doped with rare earth oxide La2O3, their varistor voltage VlmA value increased significantly; when the doping amount increased from 0.1% to 10%, the nonlinear coefficient α of the ceramic decreased from 20 to 1, and basically had no varistor properties. Therefore, for ZnO ceramics, low-concentration rare earth element doping can increase its varistor voltage value, but has little effect on the nonlinear coefficient; and high-concentration doping does not show varistor characteristics.

(3) Gas-sensitive ceramics: Since the 1970s, people have done a lot of research on the role of adding rare earth oxides to gas-sensitive ceramic materials such as ZnO, SnO2 and Fe2O3, and have produced ABO3 and A2BO4 rare earth composite oxide materials. Research results show that adding rare earth oxides to ZnO can significantly improve its sensitivity to propylene; adding CeO2 to SnO2 can produce a sintered element that is sensitive to ethanol.

(4) Thermistor ceramics: Barium titanate (BaTiO3) is the most studied and widely used thermistor ceramics. When trace rare earth elements such as La, Ce, Sm, Dy, Y, etc. are added to BaTiO3 (the molar atomic fraction is controlled to be 0.2% to 0.3%), part of Ba2+ is replaced by RE3+ with a radius similar to Ba2+, generating excess positive charges and forming weakly bound electrons through the action of Ti4+, so that the resistivity of the ceramic is significantly reduced; however, if the doping amount exceeds a certain value, due to the formation of Ba2+ vacancies and the disappearance of conductive carriers, the resistivity of the ceramic rises sharply and even becomes an insulator.

(5) Humidity-sensitive ceramics: Among the various types of humidity-sensitive ceramics, the rare earths currently added are mainly lanthanum and its oxides, such as Sr1-xLaxSnO3 system, La2O3-TiO2 system, La2O3-TiO2-V2O5 system, Sr0.95La0.05SnO3 and Pd0.91La0.09(Zr0.65Ti0.35)0.98O3-KH2PO3, etc. In order to further improve the sensitivity of humidity ceramics, in terms of realism and stability, and to enhance their practicality, it is also necessary to strengthen the research on the influence of rare earth addition on the relevant properties of ceramics.

We are specialized in export rare earth products, to buy rare earth product, welcome to contacts us

Sales@shxlchem.com; Delia@shxlchem.com

Whatsapp& tel :008613524231522; 0086 13661632459

Post time: Feb-06-2025