Pakati pezvisina-silicous oxides, alumina ane mashandiro ezvekuita, orodzokupokana, denderedzwa rakanyanya kuwanda, densorce Zvishandiso.microupus Alumina zvinowanzoshandiswa mune indasitiri, asi zvichakanganisa zvakananga chiitiko cheAlumina, hupenyu hwebasa uye kusarudzika kwezano. Semuenzaniso, mukuita kwemotokari kuneta kwakaneta, vakasvibisa kubva kuinjini mafuta ekuwedzera vanozogadzira coke, iyo ichatungamira kune iyo yekuvhara yePoryalst Pores, nokudaro ichidzora chiitiko cheCatalyst. Surfactant inogona kushandiswa kugadzirisa chimiro cheAlumina Carrier kuti ufeve ma.impono yayo catalytic performance.

Ma ane simba rekumanikidza, uye masimbi anoshanda anogadziriswa mushure mekunyanyisa tembiricha. Pamusoro pezvo, mushure mekuwedzera kwekushisa, iyo mesous mesoprous inodonha, iyo ma skeleton iri muAmorphous State, uye iyo sacidity haigoni kusangana nezvayo mumunda wekushanda. Kurapwa kunowanzodiwa kuti uvandudze chiitiko checating Skeleton.

Iyo inokosha yemagetsi yekugadziriswa kwezvinhu zvisingawanzo kuita makomputa aro ave neyakajeka Optical, magetsi uye anoshandiswa muzvinhu zvechikoro, maficha ekushandisa, zvigadzirwa zvemitambo uye zvemagineti zvinhu. Pasi risingawanzo kugadziridzwa mesous zvinhu zvinogona kugadzirisa acid Muro pepa iri, risingawanzo kugadziridzwa maMa ichaunzwa kuti uvandudze basa rekutadza, kugadzikana kwekudzivirira, okisijeni yekuchengetedza, nzvimbo yakatarwa uye pore dhizaini.

1 ma gadzirira

1.1 Kugadzirira kweAlumina Carrier

Iyo yekugadzirira nzira yeAlumina Carrier inosarudza kugovera kwayo, uye nzira dzayo dzekugadzirira dzinosanganisira Pseudo-Boehmite (PB) nzira yekushomeka uye nzira yekushomeka. Pseudoboehmite (PB) yakatanga kufungidzirwa neCalvet peturu yekuwana γ-aloh colloidal pb ine yakanyorwa mvura, iyo yaive yakadzvanywa nekudzvanywa tembiricha yekupisa. Maererano nezvinhu zvakasiyana-siyana zvekushandisa zvakaringana, zvinokonzerwa nenzira yekutanga, nzira yekubatira yePB inokanganiswa neCrystallinity, uye yakagadziriswa nekuwedzera kweCrystallinity, uye inokanganiswawo nekuita ma parmeter.

PB inowanzogadzirirwa nenzira yekutanga nzira. Alkali inowedzerwa muAluminate Solution kana Acid inowedzerwa muCouminate Solution uye yakagadzirirwa kuwana hyumina Nzira yekutanga iri nyore kushanda uye yakaderera mumutengo, iyo inowanzoshandiswa mukugadzirwa kwemaindasitiri, asi inokanganiswa nezvinhu zvakawanda (Solution ph, tembiricha, etc.).) MuCarbonization nzira, al (OH (o) 3is yakawanikwa nekuita kweCO2NAITA2, uye PB inogona kuwanikwa mushure mekukwegura. Nzira iyi ine zvakanakira kushanda kwakareruka, kusvibiswa kwechigadzirwa uye kusvibiswa kwemhando yepamusoro uye zvakakwirira zvakadzika. Aluminium Alkoxide is Hydrolyzed kuFomu Offide Moxide Moxidellarner, uye akabva abatwa kuti awane kuchena kwePB, Uniform Nekudaro, maitiro acho akaoma, uye zvakaoma kupora nekuda kwekushandiswa kweimwe ine chepfu organic sol sol sol.

Uye zvakare, inorganic salts kana organic mishonga inowanzo shandiswa kugadzirira Alumina precurs Parizvino, maitiro ekugadzirira aAlumina achiri kuvandudzwa paPB Dehydration nzira, uye nzira yekudzivirirwa yakagadzirwa nehurongwa hwakawanda

1.2 ma gadzirira

Comminal alumina haigoni kusangana nezvinodiwa zvinoshanda, saka zvakafanira kugadzirira high-performance ma. Maitiro eSynthesis anowanzo kusanganisira: Nano-casting nzira ine kabhoni mold seakaoma template; Synthesis of Sda: Evapurance-yekuzvinyudza-gungano-eUSA) muHupo hweMavara akapfava senge sda uye imwe cationic, anionic kana surfic.

1.2.1 Eisa maitiro

Iyo template yakashandiswa mune acidic mamiriro, iyo inodzivirira maitiro akaomarara uye ekutambisa nguva yeakaoma me membrane nzira uye inogona kuziva kuenderera mberi kwekuenderera mberi kwekushora. Kugadzirira kwe maEisa kwakataridzika kutarisirwa kwakawanda nekuda kwekuwanika kwayo nyore uye kubereka. Zvimiro zvakasiyana mesouses zvimiro zvinogona kugadzirira. Saizi yepora yeMa inogona kugadziriswa nekuchinja kweiyo hydrophobic keteni yeiyo hydrouss alumina (OMA), yakaiswa kune dzakasiyana-siyana dzakapfava, dzakadai saP123, F127, Triethanolaulano (Tea), etc. Eisa anogona kutsiva maitiro ezvekubata eBliness.Commin yeMesophase yakaumbwa nemidziyo yekuona sosi.

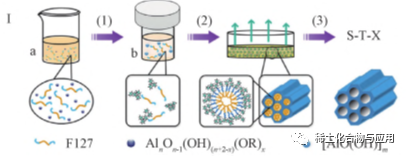

MuEuta maitiro, kushandiswa kweasina-mashoni ekunyora (senge ethanol) uye organic commencess inogona kunyatsodzora hydrousum precurs Nekudaro, mune isina-aqueltle folatle sol sol sol sol sol solventes kazhinji inowanzo kurasikirwa nehydrophilicity / hydrophosity. Mukuwedzera, nekuda kwekunonoka kwehydrolysis uye polycondensation, iyo yepakati chigadzirwa ine hydrophobic boka, rinoita kuti zviome kubata nedavira yekuona siractor. Chete kana kusungwa kweSurcentant uye degree re hydrolysis uye polycondenation ye aluminium inowedzerwa zvishoma nezvishoma mune maitiro ekuvira kwekuvira kwe template uye aluminium inoitika. Naizvozvo, ma parameter akawanda anokanganisa mamiriro emidziyo yemidziyo uye hydrolysis uye yekudzikisira maitiro, akanyorova, ane simba rekubereka rate, etc., achakanganisa chimiro chekupedzisira chegungano. Sezvinoratidzwa muPi. 1. Kurapa kweSolvothothothomal kunosimudzira iyo yakazara hydrolyslis precurss kuti iite mapoka e-aluminium hydroxyl Muitiro weEisa Euta, maitiro evapendero anoperekedzwa neHydrolysis yeBlincuminium Precursor, saka mamiriro ekuzvara ane pesvedzero yakakosha pakuita uye iyo yekupedzisira chimiro cheOMA. Iyo solvothothermal kurapwa nhanho inosimudzira iyo yakazara hydrolysis precursor uye inoburitsa chikamu chakakwenenzverwa nealuminium hydroxyl mapoka.oma inoumbwa pasi pehuremu hwakawanda hwemamiriro ezvinhu ezvekuita. Kuenzaniswa neM Ma Yakagadzirirwa Netsika EISA nzira, OMA YAKAITWA NA Sa-Eisa nzira ine yepamusoro pore vhoriyamu, nzvimbo iri nani nzvimbo uye zvirinani kugadzikana. Mune ramangwana, Eisa nzira inogona kushandiswa kugadzirira Ultra-yakakura erturture ma ine huwandu hwepamusoro hwekutendeuka uye kusarudzika kwakanakisa pasina kushandisa kutumira mumiririri.

Fig. 1 Kuyerera chati yeSa-Eisa nzira yekushongedza zvinhu zveOma

1.2.2 Mamwe maitiro

Kugadziriswa kwema kugadzirwa kunoda kudzora chaiko kweSynthesis paramita kuti uwane chimiro chakajeka mesouprous, uye kubviswa kwemidziyo ye template zvakare kwakaoma, kunoenderana nemaitiro eSynthesis. Parizvino, zvakawanda zvinyorwa zvakaratidza synthesis yeMa ine akasiyana matemplates. Mumakore achangopfuura, kutsvagisa kwakanyanya kutarisisa kuMax neGlucose, Sucranzi Ma ctab zvakare kuwanikwa nekugadziridzwa kwakananga kwePB sealuminum sosi. Ma ane akasiyana zvigadzirwa zvemidziyo, kureva al2o3) -1, Al2o3) -2 uye Al2o3and ine yakanaka yekugadzikana. Kuwedzerwa kweSurfactant hakuchinje iyo Inhent Crystal chimiro chePB, asi inoshandura maitiro ekugadzirisa ezvikamu. Uye zvakare, kuumbwa kweAl2o3-3 kunoumbwa neAdishsion yeNanoparticles yakasimbiswa neiyo organic solvent peg kana kuunganidzwa kutenderera peg. Nekudaro, iyo pore saizi yekugovera al2o3-1 yakanyanya kutetepa. Mukuwedzera, palladium-based Catalysts yakagadzirirwa neSynthetic ma seCarrierin methane Conpustion

Kekutanga, ma ane husina kutetepa saizi yekugovera yakagadzirirwa nekushandisa yakachipa uye aluminium-yakapfuma aluminium dema slag abd abd abd abd abd abd abd abd abd abd abd abd abd abd abd abd abd abd. Maitiro ekugadzira anosanganisira maitiro ekutsamwa pakudziya kwakadzika uye kujairwa. Zvivakwa zvakasimbiswa zvakasara mukuratidzira hazvizosvibise nharaunda, uye zvinogona kuunganidzwa nengozi yakaderera kana kushandiswazve seye filler kana kuunganidzwa mukushandisa kongiri. Nzvimbo yakatarwa yeiyo yakanyorwa maSynthesiz Izvo zvinyorwa ndezvekuti nano-saizi uye iyo crystal saizi ndeye 11nm. Solid-State Synthesis chiitiko chitsva chekunyora ma, izvo zvinogona kushandiswa kuburitsa radiochemical abtorbent yekushandisa kwekiriniki. Aluminium Chloride, Ammonium Carbonate uye Glucose Zvigadzirwa Zvakasanganiswa MuColar Ratio reaction. .

Kupedzisa, mune ramangwana, madiki madiki ematehwe anogona zvakare kuvhenekera yakawanda Ongorora zvakachipa templates

Nzira yekuchinja ye 2 ma

Nzira dzekusafanana nekugovera zvinhu zvinoshanda pane MA Carrier zvinosanganisira kusanganisa, mu-synthe-sis, kusanganisa, kusanganisa, pakati pevaviri vekutanga vanoshandiswa zvakanyanya.

2.1 In-St-Synthesis nzira

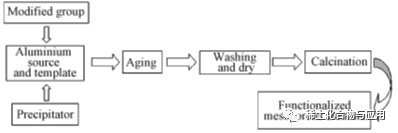

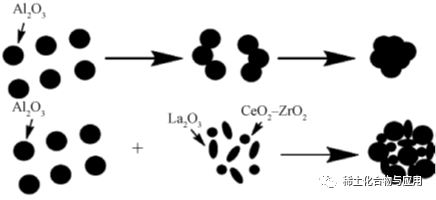

Mapoka anoshandiswa mukushanduka kweshanduro anowedzerwa mukugadzirira ma Ma kuti agadzirise uye kusimbisa chimiro cheSkeleton chezvinhu uye kugadzirisa maitiro echikuru. Maitiro acho anoratidzwa mumufananidzo 2. Liu et al. Syntheshised NI / MO-AL2O3IN STE neP123 se template. Vaviri ni na mo vakaparadzirwa murayiridzo maira, vasina kuparadza chimiro chemweya cheMa, uye maitiro ezvekutadza zvaive pachena. Kugamuchira iyo In-Sit Kukura nzira pane synthized Gamma-Al2o3Substrate, Kuenzaniswa neAK-Al2o3, MNO2-Al2o3o3 MNO2-al2o3o3has nekukurumidza adsorption rate uye kunyatsoita kweF- Iyo yekudzokorora kuita kweMNO2-al2O3is iri nani pane iyo ye γ-al2o.strul kugadzikana kunoda kuwedzeredzwa. Kupedzisa, iyo ma midziyo yakagadziridzwa yakawanikwa neIn-synthesis ine yakanaka yekudyidzana

Fig. 2 Kugadzirira kweVashandi Ma by In-Sit Synthesis

2.2 nzira yekusimbisa

Kunyudza iyo yakagadzirwa muboka rakatsanangurwa, uye kuwana iyo yakagadziridzwa maMail mushure mekurapwa, kuitira kuti uzive zvinokonzerwa necalislek, adsorption uye zvakadai. Cai et al. Yakagadzirirwa Ma kubva P123 by Sol-gel-gete nzira, uye yakanyorova muEthanol uye tetretetylepenpenpenpenppenppenppenppenppenppentiamine solution yekuwana Amino yakagadziridzwa maMail ane simba rekushambadzira kwakasimba. Mukuwedzera, belendacemi et al. Yakanyudzwa muZncl2solution neyakafanana yekuwana iyo Zinc yakachengetedzwa Zinc yakadzvanywa Kuenzaniswa neIn-Sy synthesis nzira, iyo nzira yekusimbisa ine zvinhu zviri nani, asi zvakaringana zvekushambadzira pakati pezvinhu zvinoshanda, uye chiitiko chekateni chinokanganisa nyore nyore nezvinhu zvekunze.

3 Kubudirira Kufambira Mberi

Iyo synthesis yePasi Pasi Pasi ine zvakakosha zvivakwa ndiyo iyo yekuvandudza maitiro mune ramangwana. Parizvino, pane nzira dzakawanda dzeSynthesis. Iyo pretters pretetes inokanganisa kuita kwe ma ma. Nzvimbo yakatarwa yekuona, pore vhoriyamu uye pore dhayamu inogona kugadziriswa ne template mhando uye aluminium precursor composition. Iyo tembiricha yekudziya uye polymer template kusungwa inokanganisa iyo chaiyo nzvimbo nzvimbo uye pore vhoriyamu ye ma. Suzuki naYamaauchi vakaona kuti tembiricha yekushisa yakawedzerwa kubva ku500 kusvika 900 ℃. Uye zvakare, iyo isingawanzo kujaira kuronga kunovandudza chiitiko, pamusoro pekugadzikana kweiyo, kugadzikana kwechimiro uye nzvimbo yemukati yeMagetsi, uye inosangana nekuvandudzwa kweMacommalization.

3.1 Defluorination Adsorbent

Iyo fluorine iri mumvura yekunwa muChina inokuvadza zvakanyanya. Uye zvakare, kuwedzera kweFluorine zvirimo muindasitiri zinc Sulfate Solution ichaita kuti gadziriro yeElectrod Parizvino, iyo nzira yekushambadzira ndiyo inonyanya kutaridzika pakati penzira dzakajairika dzekunyorovesa. Activated Carbon, Amorphous Alumina, activated Alumina uye mamwe adsorbents akakwira Neutral PP kukosha, asi inogumira neyekushambadzira kushambadzira kweFrOride performance.ma Kundu et al. yakagadzirirwa ma ine yakakwira fluorine adsorption kugona kwe62,5 mg / g. Iyo Fluorine Adsorption kugona kweMagetsi yakanyanya kuwanda nehunhu hwayo, senge mapoka anoshanda, saizi yepora

Nekuda kweiyo yakaoma acid ye la uye iyo yakaoma yekufambisa yeFluorine, kune hukama hwakasimba pakati peLa uye fluorine ion. Mumakore achangopfuura, zvimwe zvidzidzo zvakawana kuti LA seModifier inogona kuvandudza kushamwaridzana kweFrORIDE. Nekudaro, nekuda kwekudzika kwakadzika kwekugadzikana kwepasi adsorbents, vazhinji vepanyika vanoregedzwa mumhinduro, zvichikonzera kusvibiswa kwemvura uye kukuvadza hutano hwevanhu. Kune rimwe divi, kusvinura kwakanyanya kweAluminium munzvimbo yemvura ndeimwe yechibodzwa kuhutano hwevanhu. Naizvozvo, zvakafanira kugadzirira mhando yemhando yekubatanidza neyakagadzikana nekugadzikana kwakanaka uye kusasimira kana kushoma kusimira zvimwe zvinhu zveFluorine Kubvisa. Ma Modhified naLa uye CE akagadzirirwa neyekunyengerera nzira (La / Ma uye CE / MA). Pasi pane zvisati zvaitika Inovandudza iyo adsorption yekuwedzera yeFluorine, LA / Max ine mamwe maHydroxyl adsorption Sites, uye ADSorption Capacity ye f iri muhurongwa hweLa / Ma> CE / MA> MA> MA. Nekuwedzera kwekutanga kwekutanga, iyo adsorption kugona kweFluorine inowedzera. Uye zvakare, kusachena kweshungu ion muAlumina kunogona zvakare kukanganisa zvakanyanya kunaka kwemasampuli. Kunyangwe kutsvagisa kwakabatana pane imwe nyika kwakagadziriswa Alumina yakaitwa, kazhinji kwekutsvagisa kwakatarisana nekuita kwechidhirowa Zinc Sulfate Solution muZinc Hydrometallurgy, uye gadza nzira yekudzora maitiro ekurapa yakakwira Fluorine Solution yakavakirwa pane rare Pasi Pasi ma nano Adsorbent.

3.2 CATALYST

3.2.1 Dry Dryforming of Methane

Pasi pasirese inogona kugadzirisa acidity Izvo zvinowanzoshandiswa kutsigira masimbi akanaka uye shanduko simbi yekuchengetedza methhanation yeCo2. Parizvino, pasi risingawanzo kugadziridzwa mesous mestousy yakaoma kuomesa methaning (mdr) methane. Nekudaro, iyo yekuchinjisa uye kabhoni kubhadharwa kwe ni naneopticles pane iyo ni / al2o3eder kune yekukurumidza kujaira kweiyo catalyst. Naizvozvo, zvinodikanwa kuti uwedzere mukurumbira, shandura catelest kutakura uye kugadzirisa kugadzirira nzira yekuvandudza basa rekutadza, kugadzikana uye scorch kuramba. Muzhinji, LARE Pasi oLOWides inogona kushandiswa sechimiro uye nemagetsi anokurudzira mukukanganisa kwechikepe, uye cEO2MPROVESI yekuparadzira ni uye inoshandura zvivakwa zve simbi yekutsigira simbi yekutsigira.

Ma inonyanya kushandiswa kusimudzira kupararira kwesimbi, uye kupa kuzvidzora kwemasimbi anoshanda kudzivirira kuunganidzira kwavo. La2o3With High Exygen yekuchengetedza gadziriso inowedzera kabhoni kuramba mune zvekushandurwa kuita, uye la2o3promotes yekupararira kweCo pane mesous alumina, iyo ine basa repamusoro rekuchinja uye kusimba. Iyo LA2O3Promoter inowedzera iyo MDR chiitiko cheCO / Ma CATALYST, uye CO3O.3O.3O.OPHESS YAKABUDA KWEMAKARA.SINA 42 MuMDR process, iyo In-Sit-Insterction pakati peLA2O3and Copformed LA2O2Comed Li2o2co3mesophae, iyo yakakonzera kubviswa kunobudirira kweCXHY pane yeChialtyst Pours. La2o3promotes hydrogen kudzikiswa nekupa yakakwira emagetsi emagetsi emagetsi uye nekuvandudza oksijeni kubhadharisa mu 10% co / ma. Kuwedzerwa kweiyo la2o3reduces iyo inooneka activation simba reC4consumpt. Naizvozvo, iyo shanduko yeCh4increed kusvika ku93.7% pa 1073k K. Kuwedzera kweiyo Consection Basa, rakawedzera kushomeka kabhoni uye yakawedzera basa rekushayisana kusvika 73.3%.

CE uye pr vakatsigirwa ne ni / al2o3catalyst neine yakaenzana vhoriyamu nzira mu li xiaofeng. Mushure mekuwedzera CE uye pr, iko kusarudza kune h2increed uye kusarudzika kune col yakaderera. Iyo MDR Yakagadziridzwa naPr yakanga yakanaka CATELTIT CATALATILTIC SANGANO, uye kusarudzika kune H2Increed kubva 64.5% kusvika 75.6%, nepo kusarudzika kuCo kuderera kubva ku31.4% Peng Shujing et al. Yakashandiswa Sol-Gel nzira, CE-Modified Ma yakagadzirirwa aluminium isopropoxide, isopropanol solvent uye cerium nitrate hexahydrate. Iyo chaiyo nzvimbo yekuisa yechigadzirwa yaive yakawedzera zvishoma. Kuwedzera kwaCe kuderedza kusunganidzwa kwetsvimbo-kunge nanharticles pane ma pamusoro. Mamwe maHydroxyl mapoka ari pamusoro pe γ- Al2o3were akanyatsofukidzwa naCe ce communds. Kugadzikana kweTermal kweMa yakave yakavandudzwa, uye hapana Crystal phasitimation denderedzwa yakaitika mushure meCalcination pa1000】 kwemaawa gumi.Wang Baowei et al. yakagadzirirwa ma midziyo yeCOO2-AL2O4by Converecupation nzira. CEO2WNET Cubic zvidiki zvidiki zviyo zvaive zvakaiparadzirwa zvakaenzana muAlumina. Mushure mekutsigira CO uye Mo on CEO2-Al2o4, Kubatana Pakati peAlumina uye Active Component Co uye Mo zvakanyatsotyamadzwa neCEO2

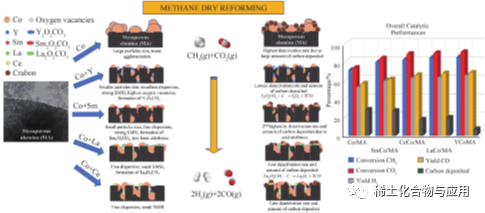

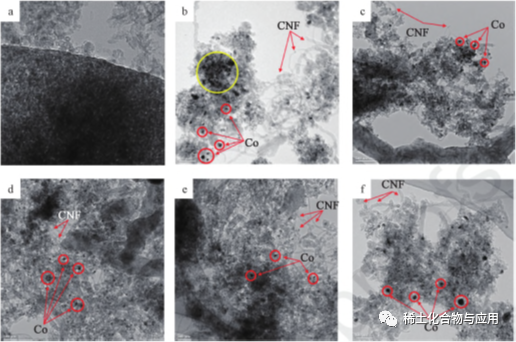

Iyo nguva isingawanzo kusimudzira (la, ce, y uye sm) inosanganiswa neCO / MA CATLIALT yeMDR, uye maitiro acho anoratidzwa muPi. 3. Vashoma vepasi vanokurudzira vanogona kuvandudza kuparadzaniswa kweCHA paMUTRIER uye inhibit iyo yakaunganidzwa ye co co cocles. Chikamu chidiki chehukuru, iyo yakasimba iyo yekubatana, iyo yakasimba iyo inokwanisa uye inokanganisa kugona kweYCO / MARIALST 4 Mufananidzo weHrtem mushure meMDR kurapwa na 1023k, CO2: CH4: N2 = 1: 1: 3.10 Maawa masere. Co zvimedu zvevaripo muchimiro chevatema matema, nepo ma anotakura zviripo muchimiro chegrey, icho chinoenderana nemusiyano wemagetsi emagetsi. Mune hrtem mufananidzo ne 10% co / ma (Fig. 4b), iyo Agglomeration yeCo Simbi inoonekwa paMatakuri Pasi Pasi Pasi Popules kusvika 11.0nm ~ 12.5nm. YCO / Ma ine yakasimba co-ma yekubatana, uye kuita kwayo kwekutadza kuri nani pane zvimwe zvinobaya. Mukuwedzera, sezvakaratidzwa mumaonde. 4b kusvika 4f, Hollow kabhoni nanowewires (CNF) inogadzirwa pane inochengeterwa, iyo inoramba ichisangana negesi kuyerera uye kudzivirira iyo inochengetera iyo yekuita deactivation.

Fig. 3 Mhedzisiro yePasi Pasi Kuwedzera Pasi pane zvemuviri uye zvemakemikari zvivakwa uye MDR Catalytic Performance yeCo / Ma Catalyst

3.2.2 DEOXIDation CATALYST

Fe2O3 / Meso-CEAL, A CE-CELED FELE DEOxidation Catalyst, yakagadzirirwa Oxidative Dehydrogenation ye 1- Butene neCo2 CE yakafurirwa zvakanyanya muAlumina Matrix, uye Fe2O3 / Meso ainyanya kuparadzira marudzi esimbi, asi ane yakanaka yekuchengetedza okisijasi, saka ine yakanaka adsorption uye activation kugona kweCo2. Sezvinoratidzwa mumufananidzo 5, tem mifananidzo inoratidza kuti fe2o3 / meso-ceal-ceal-cealsit kugadzirwa kweiyo mesoce. Iyo yakanaka simbi inochengetera midziyo yekusangana neiyo Ultra-yakaderera emission yemotokari mota yakagadzira dhizaini, yakanaka hydrothermal kugadzikana uye yakakura yekuchengetedza okisijasi.

3.2.3 CATALYST YEMADZIMAI

PD-RH inotsigira Quaternary Aluminium-Yakavakirwa Hare Pasi Pasi Yakaomesesa Alcezrtiox uye Allazrtiox Kuti Uwane Zvemotokari Catalyst CATTYS CATALATIONS CATALY BATYS CATALYST CATALATE MAHARA. Mesous Aluminium-Yakavakirwa Nyika Yepasi PD Complex PD-RH / ALC Inogona kushandiswa zvinobudirira seCPM CASHICLICE SECALICATE, uye Chinyorwa chikuru cheCGP CLEHOUST Gasi, yakakwira se97.8%. Tora nzira yehydrothermal imwe-nhanho yekugadzirira iyo zvinhu zvinonakidza zvekuzvibatanidza neyekuzvinyudza.

Fig. 4 hrtem mifananidzo ye ma (a), co / ma (b), laco / ma (c), CE), YCO / MA (E) uye SMCO / MA (F)

Fig. 5 Tem Image (a) uye EDS Element Diagram (B, C) yeFe2O3 / Meso-CEAL-100

3.3 Luminous Performance

Electrons yezvinhu zvisingawanzoitika pasi zvinhu zvinofara nyore nyore kushandura pakati pezvikamu zvakasiyana esimba uye kusununguka mwenje. Rare Pasi Pasi rinowanzoshandiswa sevatambi kuti vagadzire zvigadzirwa zveLumininent. Radza Pasi Pasi rinogona kutakurwa pamusoro peAluminium Phothphate Hollow Microspheres neCocentsitation nzira, uye Luminescent zvinhu Alpo4: LA, nd) inogona kugadzirira. Iyo Luminenzent Wave Midziyo iyi yakamisikidzwa nemafirimu ane chokwadi chekureba kwekureba, saka zvakafanira kudzora denderedzwa uye zirconie Iko kuwanikwa kwemidziyo nezvinhu zvakasiyana zvemakemikari zvimiro zvinowedzerwa, izvo zvinoita kuti zviitike kugadzira advanced photon sensors sensors. Sumo yeMa uye Oxyhydroxide Films muDhizaini Midziyo Inoratidza Kukuru Kwazvo nekuti index yakafanana neiyo yeSilicon Dioxide.Adide.Muto midziyo yemakemikari akasiyana.

3.4 Kugadzikana kweTermal

Nekuwedzera kwekudziya, kuchinjisa zvakakomba zvinokanganisa simba rekushandiswa kweMa Catalyst, uye iyo nzvimbo yekunyepedzera inoderera uye γ-al2o3in crystalline phase intions Zvisingawanzo zvepasi zvivakwa zvine chimiro chakanaka chemakemikari uye inogadziriswa, yakakwira kugadzikana, uye nyore nyore kuwanikwa uye zvakachipa zvinhu. Kuwedzera kwezvinhu zvisingawanzo kuitika kunogona kuvandudza kugadzikana kwekunyora, kwakanyanya kusimba kwekudzivirira uye manhamba ekutakura kwemutakuri, uye gadzirisa acidity yemutakuri.la uye ce ndiyo inonyanya kushandiswa uye yakadzidziswa zvinhu zvekugadzirisa. Lu Weigang nevamwe vakaona kuti kuwedzera kwezvinhu zvisingawanzo kudzivirira huwandu hwehuwandu hweAlumina. Iyo yakagadzirirwa alumina ichine nzvimbo yakakwirira yepasi pevhu uye pore vhoriyamu.howings Li yanqiu et al. Yakawedzerwa 5% LA2O3TO γ-Al2O3, iyo yakavandudza iyo yekudzikisira kugadzikana uye yakawedzera huwandu hwehuwandu uye nzvimbo yakatarwa nzvimbo yeAlumina Mutakuri. Sezvingaonekwe kubva kuhuwandu 6, la2o3added to γ-al2o3, kuvandudza iyo inogadziriswa yekudzikama yezvinhu zvisingawanzoitika pasi pevhu.

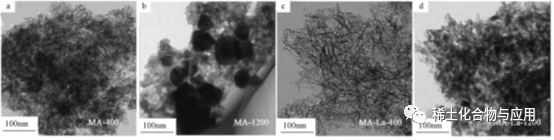

Mukuita kwekutamba nano-fibrous macustomer ne la to Sezvinoratidzwa muPi. 7, nekuwedzera kwekudziya, La inhibits maitiro ekukura kwezviyo uye shanduko yechikamu, nepo maonde. 7a uye 7c ratidza kuunganidzwa kweNano-filus zvikamu. MuDid. 7b, dhayamita yezvikamu zvakakura zvakabikwa naCalcination pa1200】 iri anenge 100nm.nm.N. inoremesa kukosha kwekutadza kweMa. Mukuwedzera, kana uchienzaniswa ne ma-1200, ma-la-1200 haichengedzana mushure mekupisa kurapwa. Nekuwedzera kwaLa, nano-fiber transle vane kugona kutadza kugona. Kunyangwe pakakwirira calcation tembiricha, diped la ichiri yakanyanya kuparadzirwa paMavhidhiyo. La Modified Ma inogona kushandiswa seyekutakura yePD CATALYST muC3H8OXIDation Reaction.

Fig. 6 Simbisa muenzaniso wekutadza alumina na uye pasina zvisingawanzo zvepasi zvinhu

Fig. 7 Tem mifananidzo yeMa-400 (a), ma-1200 (b), ma-la-400 (c) uye ma-la-1200 (d)

4 Mhedziso

Kufambira mberi kwekugadzirira uye kushanda kwekushanda kwevanhu vasingawanzo kugadziridzwa ma midziyo yakaunzwa. Pasi pasirese yakagadziridzwa ma inoshandiswa zvakanyanya. Kunyangwe kutsvagisa kwakawanda kwakaitwa mukushandiswa kwekushandisa, kugadzikana kwekunyora uye kushamisika, zviwanikwa zvakawanda zvine mutengo wakakwira, huwandu hwakaderera, kurongeka kwakashata uye kwakaoma kuva magwaro. Basa rinotevera rinofanira kuitwa mune ramangwana: Optitize kuumbwa uye chimiro chevhu chaakasingaiti chakagadziridzwa ma, sarudza maitiro akakodzera, sangana nekukura kwemabasa; Gadza nzira yekudzora yekudzora inoenderana nebasa rekuita kuti uderedze mitengo uye ziva kugadzirwa kwemaindasitiri; Kuti tiwedzere zvakanakira zveChina zvisingaiti pasi zvinhu zvinowanikwa, isu tinofanira kuongorora maitiro evanotadzisa mahusimbiso

Fund Project Project: Shaanxi Science uye Technology Yakazara Project Project (2011ktDz01-0401); Shaanxi Province 2019 Special Science Research Project (19Jk0490); 2020 Science Science Resatsotsvaga chirongwa cheHuaqing College, XI 'Iniveny University yeArtitecture uye Technology (20ky02)

Kunobva: Rare Pasi

Kutumira Nguva: Jun-15-2021