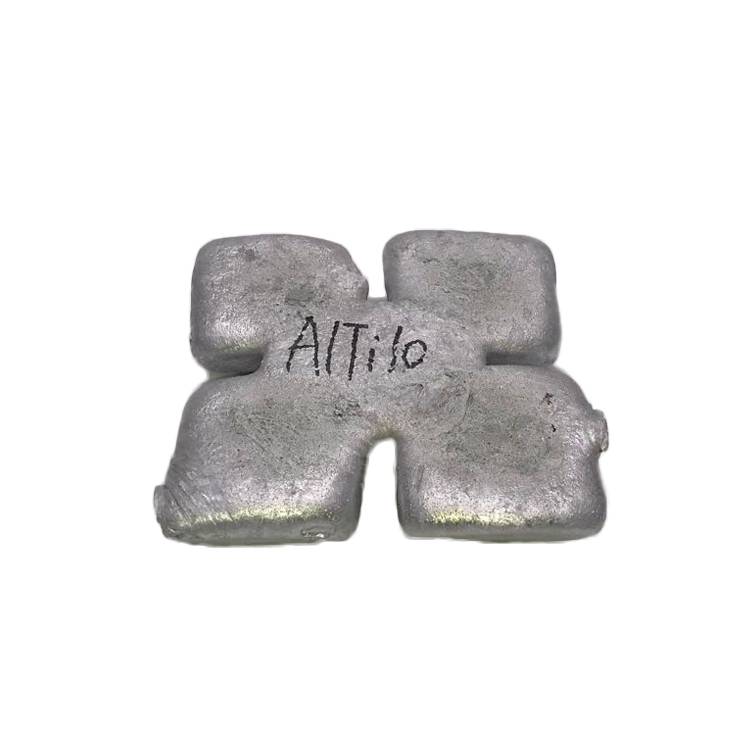

Alti10 Ingot Aluminium Titanium Masterium Master

Alti10 ingot Aluminium Titanium Master

Master alooys produk semi-parantos-parantos, sareng tiasa kabentuk dina bentukna béda. Aranjeunna campuran mutléh unsur alloying. Éta ogé dikenal salaku modifikers, hardinger, winiss diskler dumasar kana aplikasi maranéhna. Aranjeunna ditambah kana ngalembereh pikeun ngahontal hasil anu teu dibanding. Éta dianggo sanes logam murni kumargi aranjeunna épéktip énergi sareng waktosna sareng produksi.

Ngaran Produk:Aluminium Titanium Master

Singgetan:Al-ti Master

Ngaran Léndén: Aluminium Titus Master Alloy aloum, aluminium titanium Master Alloy alo, Alli Master AloL

Kontén:Alti10

Titik lebur: 102070 ° C

Formulir: Slab, waffle, Ingot, lumps, jsb

| Ngaran Produk | Titanium aluminiummaster alloy | ||||||||||||||||

| Standar | GB / T276777-2011 | ||||||||||||||||

| Eusina | Komposisi kimia ≤% | ||||||||||||||||

| Kasaimbangan | Si | Fe | Cu | Mn | Cr | Ni | Ti | B | V | Zn | Pb | Sn | Mg | C | Tunggal tunggal | Total pangotor | |

| Alti3 | Al | 0,30 | 0,35 | / | / | / | / | 2.5 ~ 3,5 | / | / | / | / | / | / | / | 0,05 | 0,15 |

| Alti4 | Al | 0,20 | 0,30 | / | / | / | / | 3.5 ~ 4,5 | / | / | 0.10 | / | / | / | / | 0,05 | 0,15 |

| Alti5 | Al | 0,50 | 0,45 | 0,15 | 0,35 | 0.10 | 0.10 | 4.5 ~ 5.5 | / | 0,25 | 0,15 | 0.10 | 0.10 | 0,50 | / | 0,05 | 0,15 |

| Alti6 | Al | 0,30 | 0,35 | / | / | / | / | 5.5 ~ 6.5 | 0,004 | 0,30 | / | / | / | / | / | 0,03 | 0.10 |

| Alti10 | Al | 0,30 | 0,35 | / | / | / | 0,05 | 9.0 ~ 11.0 | 0,004 | 0,50 | / | / | / | / | / | 0,03 | 0.10 |

| Alti6a | Al | 0,20 | 0,20 | / | / | / | / | 5.5 ~ 6.5 | 0,004 | 0,20 | / | / | / | / | / | 0,03 | 0.10 |

| Alti10a | Al | 0,20 | 0,20 | / | / | / | 0,05 | 9.0 ~ 11.0 | 0,004 | 0,20 | / | / | / | / | / | 0,03 | 0.10 |

| Alti12 | Al | 0,30 | 0,30 | / | / | 0.10 | 0.10 | 11.0 ~ 13.0 | / | 0,50 | / | / | 0.10 | / | / | 0.10 | 0,15 |

| Alti15 | Al | 0,30 | 0,30 | / | / | 0,15 | 0,15 | 14.0 ~ 16.0 | / | 0,50 | / | / | 0,15 | / | / | 0.10 | 0,15 |

| Alti3b1 | Al | 0,20 | 0,30 | / | / | / | / | 2.8 ~ 3.4 | 0.7 ~ 1.1 | / | / | / | / | / | / | 0,03 | 0.10 |

| Alli5b0.2 | Al | 0,30 | 0,35 | / | / | / | / | 4.5 ~ 5.5 | 0.15 ~ 0.25 | 0,25 | / | / | / | / | / | 0,03 | 0.10 |

| Alli5b0.2A | Al | 0,15 | 0,20 | / | / | / | / | 4.5 ~ 5.5 | 0.15 ~ 0.25 | 0,20 | / | / | / | / | / | 0,03 | 0.10 |

| Alli5b0.2b | Al | 0,30 | 0,40 | / | / | / | / | 4.5 ~ 5.5 | 0.1 ~ 0,5 | 0,20 | / | / | / | / | / | 0,03 | 0.10 |

| Alli5b0.6a | Al | 0,20 | 0,30 | / | / | / | / | 4.5 ~ 5.5 | 0,5 ~ 0.7 | / | / | / | / | / | / | 0,03 | 0.10 |

| Alti5b0.6 | Al | 0,20 | 0,30 | / | / | / | / | 4.5 ~ 5.5 | 0,5 ~ 0.7 | 0,20 | / | / | / | / | / | 0,03 | 0.10 |

| Alti5b1 | Al | 0,20 | 0,30 | / | / | / | / | 4.5 ~ 5.5 | 0.8 ~ 1.2 | 0,20 | / | / | / | / | / | 0,03 | 0.10 |

| Alli5b1A | Al | 0,15 | 0,20 | / | / | / | / | 4.8 ~ 5.2 | 0.9 ~ 1.1 | 0,05 | / | / | / | / | / | 0,03 | 0.10 |

| Alti5b1b | Al | 0,20 | 0,25 | / | / | / | / | 4.5 ~ 5.5 | 0.8 ~ 1.2 | 0.10 | / | / | / | / | / | 0,03 | 0.10 |

| Alli5b1c | Al | 0,20 | 0,30 | / | / | / | / | 4.5 ~ 5.5 | 0.4 ~ 1.2 | 0,20 | / | / | / | / | / | 0,03 | 0.10 |

| Alti3c0.15A | Al | 0,20 | 0,20 | / | / | / | / | 2.6 ~ 3.4 | 0,004 | 0,05 | / | / | / | / | 0,08 ~ 0.22 | 0,03 | 0.10 |

| Alti3c0.15 | Al | 0,30 | 0,15 | / | / | / | / | 2.6 ~ 3.4 | 0,004 | 0,30 | / | / | / | / | 0,08 ~ 0.22 | 0,03 | 0.10 |

| Alti3c0.3 | Al | 0,20 | 0,20 | / | / | / | / | 2.6 ~ 3.4 | 0,004 | 0,05 | / | / | / | / | 0,25 ~ 0.35 | 0,03 | 0.10 |

| Sambungan | 1. Hardenders: dianggo pikeun ningkatkeun fisik sareng mékanis sipat alloys logam. 2. Pelompok greeners: dianggo pikeun ngatur panyebaran kristal individu individu inchal individu pikeun ngahasilkeun struktur anu langkung saé sareng langkung seragam. 3. Moderriers & alloys khusus: biasana dianggo pikeun ningkatkeun kakuatan, duklability sareng mesin. | ||||||||||||||||

| Produk séjén | Rummei,Alti,Alni,Alv,Alsr,Alzr,Alca,Ali,Alfe,Alcu, Alkr,Alb, Alre,Albe,Albi, Alo.Aluman, Alw,Algg, Alzn, alsn,Alci,Aly,Alla, Alpr, alnd, alyb,Alsc, jsb | ||||||||||||||||

Sertipikat:

Naon anu urang tiasa nyayogikeun: