Phakathi kwama-oxides angewona alesilihle, i-alumina inezakhiwo ezinhle zemishini, ukumelana kwezinga lokushisa kanye nokuphikiswa kokugqwala, ngenkathi i-alumina ye-mesoporous, i-advorption kanye nokuqhekeka, okuhlangenwe nakho kwe-addrofesulization, i-hydricracking kanye ne-hydrodesulfulization of petroleum eluhlaza Izinto zokwakha.micropororous Alumina zivame ukusetshenziswa embonini, kepha zizothinta ngqo umsebenzi we-alumina, impilo yenkonzo kanye nokukhetha kwe-catalyst. Isibonelo, enqubweni yokuhlanzwa kokuphela kwezimoto, ukungcoliswa kwezimoto ezifakiwe kusuka ezingeni likawoyela enjini kuzothatha i-coke, ezoholela ekuqhekekeni kwama-pores actalyst, ngaleyo ndlela kunciphise umsebenzi we-catalyst. I-Surfactant ingasetshenziswa ukulungisa ukwakheka kwesakhiwo sase-Alumina Carriers ukuze kwakhiwe i-Ma.Improve ukusebenza kwayo kwe-catalytic.

I-MA inomphumela wokucindezela, kanye nezinsimbi ezisebenzayo zenziwa kusebenze ngemuva kwe-caltination ephezulu yokushisa. Ngaphezu kwalokho, ngemuva kwe-callonation ephezulu yokushisa, isakhiwo esimnandi siyawa, i-MA Skeleton isesimweni esihle, futhi i-acidity yangaphandle ayikwazi ukufeza izidingo zayo emkhakheni wokusebenza. Ukwelashwa kokuguqulwa kuvame ukudingeka ukuthuthukisa umsebenzi we-catalytic, ukuqina kwesakhiwo okuhlangene ngaphezulu kwe-MA noma idonswe emanzini.

Ukucushwa okukhethekile kwe-elektroni okwenziwa izinto zomhlaba ezingavamile kwenza ukuthi amakhompiyutha awo abe nezinto ezikhethekile ze-Optical, ugesi nezezibuthe, futhi zisetshenziswa ngezinto zokwenziwa ze-catalytic, izinto zokwenziwa kwezithombe, izinto zokwenziwa kahle kanye nezintokazi. Izinto ezi-Mesopororororororororororororororororor eziguquliwe zingashintsha impahla ye-acid (alkali), zandisa izikhala ze-oksijini, futhi zihlanganisa insimbi ye-nanocrystaltine enesikali esilinganiswayo kanye nokuqina kwe-carbomer Kuleli phepha, ukuguqulwa komhlaba okungavamile nokusebenza kwe-MA kuzokwethulwa ukuthuthukisa ukusebenza kwe-catalytic, ukuqina okushisayo, umthamo wokugcina umoya-mpilo, indawo ethize yendawo ye-pore kanye nesakhiwo esithile.

1 MA Ukulungiselela

1.1 Ukulungiswa kwe-Alumina Carrier

Indlela yokulungiselela i-Alumina Carrier inquma ukusatshalaliswa kwesakhiwo sayo, futhi izindlela zayo zokulungiselela ezivamile zifaka indlela yokuphelelwa yi-Pseudo-Boehmite (PB) nendlela ye-sol-gel. I-Pseudoboboehmite (PB) iphakanyiswe kuqala yiCalvet, futhi i-H + yathuthukisa i-potveralization ukuthola i-γ-colloih colloidal PB equkethe amanzi okuhlanyelwa, awohloka amanzi okushisa aphezulu enze u-Alumina. Ngokuya ngezinto ezahlukahlukene eziluhlaza, kuvame ukuhlukaniswa ngendlela yemvula, indlela ye-carbonialization kanye ne-colloidalinum hydrolysis Method.Indlela ye-colloidal hydrolysis.Indlela ye-colloidal ye-PB iyathinteka yi-crystaltaltity, futhi ilungiselelwe ngokwanda kwe-crystallity, futhi kuyamiswa futhi ngamapharamitha enqubo yokusebenza.

I-PB ivame ukulungiswa yindlela yemvula. U-Alkali ungezwe kwikhambi le-Aluminate noma i-acid yengezwa kwikhambi le-aluminate futhi anenqwaba yokuthola i-alumina ye-alumina (noma i-acipitate enyathelweni yemvelo yokuthola i-alumina ukuthola i-alumina monohydrate, bese igezwa futhi ifakwe ukuze ithole i-PB. Indlela ye-Preciditation kulula ukuyisebenzisa futhi iphansi kakhulu, okuvame ukusetshenziswa ekukhiqizeni kwezimboni, kepha ithonywa yizinto eziningi (isixazululo ph, ukugxila, izinga lokutholwa, njll.). Futhi leso simo sokuthola izinhlayiyana ngokuqinile siqine. Ngendlela ye-carbonization, al (oh) 3is etholwe ngokusabela kweCo2 Naalo2, ne-PB ingatholwa ngemuva kokuguga. Le ndlela inezinzuzo zokusebenza okulula, ikhwalithi ephezulu yomkhiqizo, akukho ukungcoliswa kanye nezindleko eziphansi, futhi kungalungiselela i-alumina ngomsebenzi ophakeme we-catalytic, indlela ephakeme yokugqwala kanye ne-ancoxide ye-hydrolysis indlela evame ukusetshenziselwa ukulungisa i-PB ehlanzekile. I-Aluminium Alkoxide ihlelwe yi-aluminium oximane oxide monohydrate, bese iyelapha ukuthola i-PB ehlanzayo ephezulu, enobukhulu obuhle, usayizi we-pore usayizi we-pore kanye nobuqotho obuphezulu bezinhlayiya eziyindilinga. Kodwa-ke, inqubo iyinkimbinkimbi, futhi kunzima ukuyithola ngenxa yokusetshenziswa kwezinto ezithile ezinobuthi ezinobuthi.

Ngaphezu kwalokho, usawoti we-inorganic noma amakhompiyutha e-organic wezinsimbi asetshenziselwa ukulungiselela ama-alumina wangaphambilini ngendlela ye-sol-gel, kanye namanzi ahlanzekile noma ama-solvents arganic noma ama-solvents anqondo afakiwe ukulungiselela izisombululo zokukhiqiza i-sol, esezomile bese zigazinga. Njengamanje, inqubo yokulungiselela i-alumina isathuthukiswa ngesisekelo sendlela ye-PB Dehydration, futhi indlela ye-carbonization isibe yindlela esemsono yezomnotho kanye nokuvikelwa kwezemvelo okuwukusatshalaliswa kwe-sol-gel indlela, kodwa kudinga ukwenziwa ngcono ukuze kuqashelwe ukusetshenziswa kwezimboni.

I-1.2 MA Ukulungiselela

I-Alumina evamile ayikwazi ukufeza izidingo ezisebenzayo, ngakho-ke kuyadingeka ukulungiselela i-maugh-performance ma. Izindlela zokwenziwa zivame ukufaka: indlela yokusakaza ye-nano ngesikhunta kakhabhoni njengethempulethi enzima; Ukuhlanganiswa kwe-SDA: Inqubo yokuzijabulisa okubangelwa ukuhwamuka (i-Eisa) ekhona izifanekiso ezithambile ezifana ne-SDA nezinye iziqu ze-anionic noma ezingekho emthethweni.

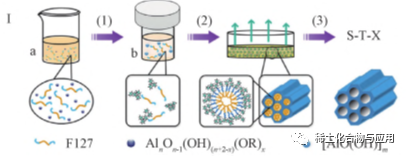

1.2.1 Inqubo ye-EISA

Isifanekiso esithambile sisetshenziswa esimweni se-acidic, esivikela inqubo eyinkimbinkimbi futhi edla isikhathi yendlela enzima ye-membrane futhi ingabona ukuguquguquka okuqhubekayo kokuhlaziywa kwe-aperture. Ukulungiswa kukaMa ngu-Eisa kudonsele ukunakwa okuningi ngenxa yokutholakala kwayo okulula nokuvela kabusha. Izakhiwo ezahlukahlukene ze-mesoporous zingalungiswa. Usayizi we-pore of Ma ungashintshwa ngokushintsha ubude be-hydrophobic chain buttle of surdrophobic of surdractant noma ukuguqula isilinganiso se-motar of aluminis prepalyst ku-Aluminium Presina yendawo ephezulu ye-Aluminium endaweni ephezulu yendawo ye-MA futhi i-OMA), isetshenziselwe izifanekiso ezahlukahlukene ezithambile, njenge I-P123, F127, Triethanolamine (itiye), njll. Eisa angangena esikhundleni senqubo yokuhlangana kwe-OrganoAluminum Preserron, njenge-Aluminium Alkocoxides kanye ne-P123, ukuhlinzeka ngempumelelo kwenqubo ye-EISA kudinga ukulungiswa okuqondile kwe-hydrolysis kanye nokuvuselelwa I-Kinetics yokuthola i-Steal Sol futhi ivumele ukuthuthukiswa kweMesophase okwakhelwe yiMicelles EseSurfactant eSol.

Enqubweni ye-EISA, ukusetshenziswa kwama-solvents angewona amanzi (njenge-ethanol) kanye ne-organic ezincome ama-ejenti anganciphisa ngempumelelo i-hydrolysis kanye ne-aulsonsation of argaaluminum presion futhi angezelele ukuzibandakanya kwezinto ze-OMA, njenge-al (noma) i-aluminium sesproproprocide. Kodwa-ke, kuma-solvents angenamathuba, izifanekiso ezisetshenziswayo zivame ukuphelelwa yi-hydrophicility / hydrophopobicity yazo. Ngaphezu kwalokho, ngenxa yokubambezeleka kwe-hydrolysis kanye ne-polycondenation, umkhiqizo ophakathi nendawo une-hydrophobic group, okwenza kube nzima ukuxhumana ne-supfantant template. Kuphela lapho ukugcwala kwe-surdioly kanye ne-degree of aluminium ne-aluminium kancane inyuswa kancane kancane kwinqubo ye-solvent irouse can self emhlanganweni wethempulethi ne-aluminium yenzeka. Ngakho-ke, amapharamitha amaningi athinta izimo zokuhwamuka ze-solvents kanye ne-hydrolysis nokuvuselelwa kwangaphambili, okufana nokushisa, isilinganiso somoya, kuzothinta izinga lokuhwamuka komhlangano. Njengoba kukhonjisiwe ku-Fig. 1, Oma izinto zokwenziwa ngokuqina okuphezulu kanye nokusebenza okuphezulu kwe-catalytic kwahlanganiswa ukuhwamuka kwe-solvothermal okusizwa ukuzibandakanya (i-SA-EISA). Ukwelashwa kweSolrothermal kukhuthaze i-hydrolysis ephelele eyedlule ukwakha amaqembu amancane weqembu le-aluminium hydroxyl, okuthuthukisiwe i-hexagonal menophase ye-aluminin Enqubweni yendabuko ye-EISA, inqubo yokuhwamuka ihambisana ne-hydrolysis ye-orgaoaluminum premursor, ngakho-ke izimo zokuhwamuka ziba nethonya elibalulekile ekuphenduleni nasekwakhiweni kokugcina kwe-OMA. Isinyathelo sokwelashwa se-solvothermal sikhuthaza ama-hydrolysis aphelele we-aluminium premursor futhi akhiqize ngokwengxenye aluminium hydroxyl green.Oma yakhelwa ngaphansi kwezimo ezahlukahlukene zokuhwamuka. Uma kuqhathaniswa ne-Ma Make elungiselelwe yindlela yendabuko ye-EIS, i-OMA elungiselelwe yi-SA-EISA Indlela ephakeme ye-Pore Volume, indawo ethize yendawo ethile kanye nokuqina okungcono okushisayo. Esikhathini esizayo, indlela ye-EISA ingasetshenziswa ukulungiselela i-altrale-enkulu ye-aperture ngenani eliphakeme lokuguqula nokukhetha okuhle ngaphandle kokusebenzisa i-ejenti yokuvuselela.

I-Fig. 1 Ishadi lokugeleza kwendlela ye-SA-eisa yokuhlanganisa izinto ze-OMA

1.2.2 Ezinye izinqubo

Ukulungiselela okujwayelekile kwe-MA kudinga ukulawula okuqondile kwamapharamitha wokuhlekisa ukufezekisa ukwakheka okucacile okuhle, futhi ukususwa kwezinto zethempulethi nakho kuyinselele, okubonisa inqubo yokuhlanganiswa. Njengamanje, amawavi amaningi abike ukuhlanganiswa kwe-MA ngezifanekiso ezahlukahlukene. Eminyakeni yamuva nje, ucwaningo lugxile kakhulu ekuhlolweni kukaMai nge-glucose, i-sucrose kanye nesitashi njengezibonisi ze-aluminium sopropoxide ku-aluminium nitrate, i-alfate kanye alkoxide njengemithombo ye-aluminium. I-MA CTAB nayo itholwe ngokuguqulwa okuqondile kwe-PB njengomthombo we-aluminium. I-MA enezakhiwo ezahlukahlukene zezakhiwo, ie al2o3) -1, i-al2o3) -2 ne-al2o3and inokuqina okuhle okushisayo. Ukungezwa kwe-surfactant akushintshi ukwakheka kwe-Crystal ye-PB, kepha kushintsha imodi yokufaka yezinhlayiya. Ngaphezu kwalokho, ukwakheka kwe-al2o3-3 kwakhiwa ukunamathela kwama-nanoparticles aqiniswe yi-organic solvent Peg noma i-aggregation ezungeze isikhonkwane. Kodwa-ke, ukusatshalaliswa kosayizi we-AL2O3-1 kuncane kakhulu. Ngaphezu kwalokho, ama-calladium asuselwa ePalladium alungiswe nge-zokwenziwa main njengoba ephethe.in Ukusabela kwe-methane, i-catalyst esekelwa yi-al2o3-3 ikhombisa ukusebenza okuhle kwe-catalytic.

Ngokokuqala ngqa, ama-Ma nosayizi omncane we-pore usayizi wawulungiswa ngokusebenzisa i-aluminium-rich-rich aluminium black slagb. Inqubo yokukhiqiza ifaka inqubo yokukhishwa kwamazinga okushisa aphansi kanye nengcindezi ejwayelekile. Izinhlayiya eziqinile ezishiywe kwinqubo yokukhipha ngeke zingcolise imvelo, futhi zingafakwa engcupheni ephansi noma zisetshenziswe kabusha njengoFlerler noma ihlanganiswe nesicelo sikakhonkolo. Indawo ethile engaphezulu ye-Synthesised Ma ingu-123 ~ 162m2 / g, ukusatshalaliswa kosayizi we-pore kuyinto emincane, i-peak radius ngu-5.37 cm3 / g. Okuqukethwe yi-nano-usayizi kanye nosayizi wekristalu cishe ngo-11nm. Ukuhlanganiswa okuqinile kombuso kuyinqubo entsha yokuhlanganisa i-MA, engasetshenziselwa ukukhiqiza umsakazo wokuhlangelela komklamo. I-Aluminium Chloride, i-ammonium carbonate kanye nezinto zokwenziwa ze-glucose zixutshaniswa nesilinganiso se-molar of 1: 1.5: 1.5, futhi i-MA ihlanganiswe nge-arcention entsha ye-acceriochemical ye-131i ngemuva kokuhlushwa i-90% .

Ukufingqa, ngokuzayo, izifanekiso ezincane zama-molecular nazo zingathuthukiswa ukwakha izakhiwo eziningi ze-Pore-Level, zilungisa ngempumelelo ukwakheka, i-morphology kanye nendawo enkulu yamakhemikhali bese kukhipha indawo enkulu ye-wormmole ma. Hlola izifanekiso ezishibhile nemithombo ye-aluminium, uthuthukise inqubo yokuhlanganisa, ucacise indlela yokuhlanganiswa futhi uqondise inqubo.

Indlela yokuguqulwa ye-2 MA

Izindlela zokusabalalisa ngokulinganayo ezingxenyeni ezisebenzayo ku-MA Carriers zifaka ukuthengiswa, ukushintshana kwezulu, ukushintshana kwezulu, ukuxubana kwemishini nokuncibilikisa, phakathi kokuqala okubili okusetshenziswa kakhulu.

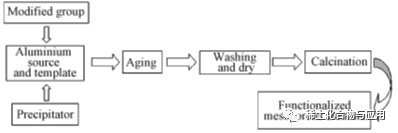

2.1 in-situ synthesis indlela

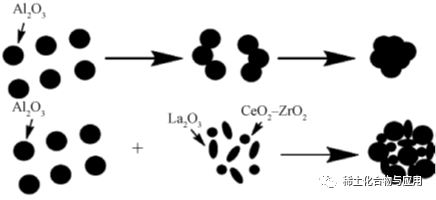

Amaqembu asetshenziswa ekuguqukeni okusebenzayo angezwa kwinqubo yokulungiselela i-MA ukuguqula futhi aqinise ukwakheka kwesikhumba salokho okuqukethwe futhi athuthukise ukusebenza kwe-catalytic. Inqubo ikhonjiswa kuMfanekiso 2. U-Liu et al. Synthesised NI / MO-al2o3in situ nge-P123 njengethempulethi. Bobabili uNi no-Mo bahlakazeka ku-Odwana iziteshi ze-MA, ngaphandle kokubhubhisa ukwakheka okuhle kwe-MA, kanti ukusebenza kwe-catalytic kusobala. Ukwamukela indlela yokukhula kwe-In-CuTU e-Gamma-Al2o3Substrate, uma kuqhathaniswa ne-γ-al2o3, i-MNO2-Al2o3has enkulu ye-Peace Surface neVolumu ye-Pore, futhi inesakhiwo se-bimodal mesoporous ngokusatshalaliswa kosayizi omncane. I-MNO2-Al2o3has Fast Adsorption Rate kanye nokusebenza kahle kwe-F-, futhi kunebanga elibanzi le-PH (PH = 4 ~ 10), elilungele izimo zohlelo lokusebenza lwezimboni. Ukusebenza kabusha kwe-MNO2-Al2o3is okungcono kunalokho kwe-γ-al2o.structuratural ukuqina kudinga ukwenziwa kabusha. Ukufingqa, izinto eziguquliwe ze-MA ezitholwe ngu-Situ synthesis zinokuhleleka okuhle kwesakhiwo, ukuxhumana okuqinile phakathi kwamaqembu nabathwali be-Alumina, futhi akulula ukudala ukuchithwa kwezinto ezisebenzayo kwinqubo yokusabela kwe-catalytic, kanye nokusebenza kwe-catalytic kuthuthukiswa kakhulu.

Fig. 2 Ukulungiswa kwe-MA okusebenzayo ngo-in-situ synthesis

2.2 Indlela Yokubika

Ukufaka i-MA elungiselelwe eqenjini eliguquliwe, futhi uthole impahla eguquliwe ye-MA ngemuva kokwelashwa, ukuze kufezeke imiphumela ye-catalysis, ama-adsorption kanye nokunye. Cai et al. Ilungiselelwe mama kusuka ku-P123 ngendlela ye-sol-gel, futhi ifakwe emanzini e-ethanol kanye ne-tetraethylepentamine solution ukuthola impahla ye-amino modined Mated. Ngaphezu kwalokho, eBelkacemi et al. I-SNCLS2SOLUTION nge-znclcl2solution ngenqubo efanayo yokuthola i-Zinc Doped Medified Mation Medified Mates.Indawo ethize yendawo kanye nevolumu ye-pore kungama-3945 / g kanye ne-0.55 cm3 / g, ngokulandelana. Uma kuqhathaniswa ne-In-Situ synthesis indlela, indlela yokufakwa emthethweni inokuhlakazeka okungcono kwento, isakhiwo esihle sokuhlanza nokusebenza okuhle kwe-adsorption, kepha amandla okuxhumana abuthakathaka, futhi umsebenzi we-catalytina ubuthakathaka kalula yizinto zangaphandle.

3 Intuthuko Esebenzayo

Ukuhlanganiswa kwe-Rare Earth Ma ne-Special Properties yindlela yokuthuthuka ngokuzayo. Njengamanje, kunezindlela eziningi ze-synthesis. Amapharamitha enqubo athinta ukusebenza kwe-MA. Indawo ethile engaphezulu, ivolumu ye-pore kanye ne-pore ubukhulu be-MA ingashintshwa ngohlobo lwethempulethi kanye nokwakheka kwe-aluminium Premusition. Ukuhlaziywa kwe-calconate kanye ne-polymer template yokuhlobisa kuthinta indawo ethile engaphezulu kanye nevolumu ye-MA. USuzuki noYamauchi bathola ukuthi izinga lokushisa le-caltch lenyuswe lisuka ku-500 ℃ kuya ku-900 ℃ .Ukuphakanyiswa kungandiswa futhi indawo engaphezulu ingancishiswa. Ngaphezu kwalokho, ukwelashwa kokuguqulwa komhlaba okungavamile kuthuthukisa umsebenzi, ukuqina okushisayo, ukuqina kwesakhiwo kanye nokuqina kwe-acidity yezinto ze-MA kwinqubo ye-catalytic, futhi kuhlangabezana nokuthuthukiswa kokusebenza kwe-MA.

3.1 defluorination adsorbent

I-fluorine emanzini okuphuza amanzi eChina iyingozi kakhulu. Ngaphezu kwalokho, ukwanda kokuqukethwe kwe-fluorine kwisixazululo sezimboni ze-zinc sulfate kuzoholela ekugcekeni kwe-electrode yendawo, ukwehla kwenani lamanzi avuselelayo kuhlelo lwe-acid lwenza i-fluased system yokugazinga igesi. Njengamanje, indlela ye-adsorption iyona ekhangayo kakhulu phakathi kwezindlela ezijwayelekile zokungcolisa okumanzi.I-Hever, kukhona amaphutha, anjengamandla ampofu we-adsorption, ukungcoliswa kwesibili, ukungcoliswa kwesibili nokunye. I-Carbon ecushiwe ecushiwe, i-alumina ye-alumina eyenziwe nge-alumina eyenziwe ngezinye futhi i-adumina isetshenziselwe ukungcola kwamanzi, kepha izindleko zama-adumina ziphakeme kakhulu, futhi i-alumina ephezulu i-alumina i-adumide ephansi yokususa i-fluoride ye-fluoride ye-fluoride ngenxa ye-fluoride yayo ephezulu, kepha i-fluoride yenani eliphakeme, kepha lilinganiselwe yi Umthamo ongemuhle we-adsorption we-fluoride, futhi kuphela ongaba ne-fluoride adsorption ukusebenza kwe-fluoride adsorption.Akudonsele ukunakwa kakhulu ekuphathweni kokungcoliswa kwemvelo ngenxa yendawo yayo enkulu engaphezulu, umphumela ohlukile we-pore, ukusebenza okushisayo nokwenziwa ngomshini. Kundu et al. Ilungiselelwe Ma nge-Fineral Fluorine Adsorption Amandla we-62.5 mg / g. Amandla we-fluorine adscoption we-mad athonywa kakhulu yizici zawo zokwakheka, njengendawo ethize yendawo, amaqembu okusebenza komhlaba, usayizi we-pore kanye nosayizi wezokwakhiwo kanye nokwenza isisekelo sesakhiwo nokusebenza kwe-MA kuyindlela ebalulekile yokuthuthukisa ukusebenza kwayo ama-adsorption.

Ngenxa ye-hard acid ye-LA kanye nobungqabavu obunzima be-fluorine, kunobumbano oluqinile phakathi kwe-LA nama-ion we-fluorine. Eminyakeni yamuva, ezinye izifundo zithole ukuthi i-LA njenge-modifier ingathuthukisa amandla we-adsorption we-fluoride. Kodwa-ke, ngenxa yokuqina kwesakhiwo okuphansi kwezinhlelo zomhlaba ezingandile Earth Adeders, umhlaba ongavamile uboshwe kwikhambi, okuholele ekungcoleni kwamanzi kwesibili nokulimaza impilo yabantu. Ngakolunye uhlangothi, ukugxila okuphezulu kwe-aluminium endaweni yamanzi kungenye yezingcucuko empilweni yabantu. Ngakho-ke, kuyadingeka ukulungiselela uhlobo lwe-adsorbent eyinhlanganisela ngokuqina okuhle futhi akukho okufakwayo noma ukufakwa okuncane kwezinye izinto kwinqubo yokususa i-fluorine. I-MA iguqulwe nguLa ne-CE yalungiswa yindlela yokufaka (LA / MA ne-CE / MA). Ama-oxide e-Rare Earth alayishwe ngempumelelo ePoplace Okokuqala, okwakukhona ukusebenza okuphezulu kwe-Defluorination.Izindlela zokususwa kwe-Fluorine, ukuguqulwa kwe-elektroni, ukuguqulwa kwe-LA kanye ne-CE kuthuthukisa umthamo we-adrorption we I-Fluorine, i-LA / MA iqukethe amasayithi amaningi we-hydroxyl adsorption, futhi amandla e-adsorption we-F ahlelekile we-LA / MA> CE / MA> Ma> Ma. Ngokwenyuka kokuhlushwa kokuqala, umthamo we-adsorption we-fluorine akhuphuka.Umphumela we-adsorption ungcono kakhulu lapho i-PH ingu-5 ~ 9, kanye nenqubo ye-adsorption ye-fluorine i-adsorption model. Ngaphezu kwalokho, ukungcola kwama-ion sulfate e-alumina nakho kungathinta kakhulu ikhwalithi yamasampula. Yize ucwaningo oluhlobene no-Alumina olungafani nolu-Alumina lwenziwe, iningi locwaningo lugxile kwinqubo ye-adsororbent, okukusasa, sikwazi ukufundela i-fluorine ion adsorbent yokuhlehlisa i-ion adsorbent yokuzikhandla kwe-Zinc Sulfate Solution in Uhlelo lwe-Zinc hydrometurgy, futhi lusungule imodeli yokulawula inqubo yokwelapha isisombululo esiphezulu se-fluorine ngokususelwa emhlabathini ongavamile emhlabeni ma nano adsorbent.

3.2 Catalyst

3.2.1 Ukuguqulwa komile kwe-methane

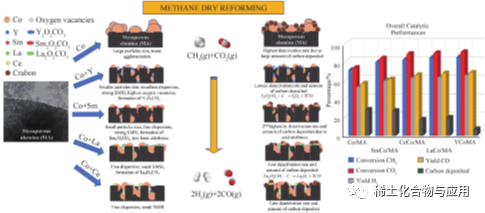

Umhlaba ongavamile ungaguqula i-acidity (isisekelo) yezinto zokwakha i-porous, khulisa izikhala ze-oxygen, futhi uhlanganise ama-catalysts ngokuhlakazeka okufanayo, isilinganiselo se-nanomemeter nokuqina. Imvamisa isetshenziselwa ukusekela izinsimbi ezinhle nezinsimbi zokuguqula ukulinganisa i-methanation ye-CO2. Njengamanje, izinto ezingavamile zomhlaba eziguquliwe zithuthukisa i-methane Reform (MDR), ukuwohloka kwe-vocs kanye ne-PD, i-CO, FE, njll.) Kusetshenziswa kabanzi ngomsebenzi wayo ophakeme we-catalytic futhi Ukukhetha, ukuqina okuphezulu nezindleko eziphansi ze-methane. Kodwa-ke, ukubekwa kwesono kanye nekhabhoni yama-ni nanoparticles angaphezulu kwe-NI / Al2o3lead kuya ekusebenzeni okusheshayo kwe-catalyst. Ngakho-ke, kuyadingeka ukufaka i-accelerant, shintsha umthwali we-catalyst futhi uthuthukise indlela yokulungiselela ukuze uthuthukise umsebenzi we-catalytic, ukuqina kanye nokuphikiswa kombhede. Ngokuvamile, izinkohliso zomhlaba ezingavamile zingasetshenziswa njengezikhulikazi zesakhiwo kanye ne-elekthronikhi kuma-heterogenests, kanye ne-CEO2Impperes Ukuhlakazwa kwe-NI futhi kushintshe izindawo ze-Metallic NI zokusekelwa kwensimbi.

I-MA isetshenziswa kabanzi ukuthuthukisa ukuhlakazwa kwezinsimbi, futhi inikeze ukuvinjezelwa kwezinsimbi ezisebenzayo ukuvikela i-agglomeration yazo. I-LA2O3With High Oxygen Gcina amandla athuthukisa ukumelana nekhabhoni enqubweni yokuguqulwa, kanye ne-LA2O3Promotes Ukuhlakazwa kwe-CO ku-Alumina Mesoporous, onomsebenzi ophezulu wokuguqula nokuqina. I-LA2O3Promoter inyusa umsebenzi we-MDR we-CO / MA Caallyst, kanti ama-Co3o4and Coal2o4o4o4o4sses akhiwa endaweni ebabazekayo. Ezinhlelweni ze-MDR, ukuxhumana kwe-In-Situ phakathi kweLa2o3AND COO2ORFEDE LO2O2CO3Mesesophase, okunxenxa ukuqedwa okusebenzayo kwe-CXHY ku-Catalyst Surpy. I-LA2O3Promotes Redrogen ukuncishiswa ngokunikeza amandla aphezulu e-electron kanye nokwenza ngcono i-oxygen chanckanc in 10% CO / MA. Ukungezwa kweLa2o3ressed amandla awo activation amandla we-Ch4Conpusup. Ngakho-ke, isilinganiso sokuguqulwa se-ch4increase safinyelela ku-93.7% ku-1073k K. Ukufakwa kwe-LA2O3IMPROVE

I-CE ne-PR yasekelwa ku-NI / Al2o3catalyst ngendlela elinganayo yokufakwa kwevolumu ku-Liaofeng. Ngemuva kokungezwa kwe-CE ne-PR, ukukhetha ku-H2increased kanye nokukhetha okunciphile. I-MDR elungisiwe yi-PR yayinekhono elihle kakhulu le-catalytic, kanye nokukhetha ku-H2increase kusuka ku-64,5% kuya ku-75.6%, ngenkathi u-SeleCH Indlela ye-SOL-GEL, i-CE-Modified Ma ilungiselelwe nge-aluminium isopropoxide, i-sopropanol solvent kanye ne-cerium nitrate hexahydrate. Indawo ethile engaphezulu yomkhiqizo yanda kancane. Ukungezelelwa kwe-CE kunciphise ukuhlanganiswa kwama-nanoparticles afana ne-rod Amanye amaqembu e-hydroxyl ngaphezulu kwe-γ- al2o3were embozwe ngokuyisisekelo amakhompiyutha e-C ce. Ukuqina okushisayo kwe-MA kwenziwa ngcono, futhi akukho shintsho lesigaba se-crystal senzeka ngemuva kwe-1000 ℃ yamahora ayi-10.Wang Baowei et al. Ilungiselelwe i-MA Material CEO2-Al2o4o4by Coprecipipation indlela. I-CEO2With cubic tiny okusanhlamvu kwahlakazwa ngendlela efanayo e-Alumina. Ngemuva kokuxhasa uCe no-MO ku-CEO2-Al2o4, ukuxhumana phakathi kwe-Alumina ne-Contenent Co kanye no-Mo kwavinjelwe ngempumelelo yi-CEO2

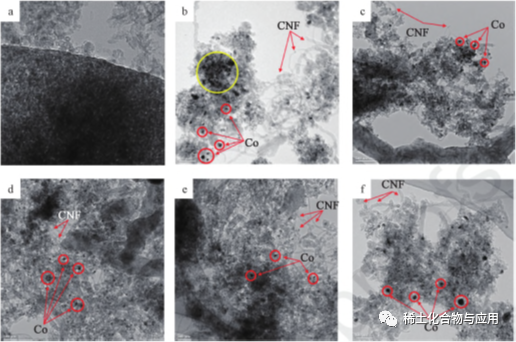

Abagqugquzeli be-Rare Earth (LA, CE, Y ne-SMA) bahlanganiswe ne-CO / MA Catalyst ye-MDR, futhi inqubo ikhonjiswa ku-Fig. 3. Abagqugquzeli bomhlaba abangavamile bangathuthukisa ukuhlakazwa kwe-CO On Mar Carriers futhi bavimbele i-agglomeration yezinhlayiya. Ubukhulu bezinhlayiyana, ubungako be-co-MA, obuqine ngekhono le-catalytic nesono e-yco / ma catalyst, nemiphumela emihle yabagqugquzeli abaningana kwi-MDR imisebenzi kanye ne-carbon depin.Fig. I-4 isithombe se-HRTEM ngemuva kokwelashwa kwe-MDR ku-1023k, CO2: CH4: N2 = 1: 1: 3.1 amahora angu-8. Izinhlayiya ze-CO zikhona ngesimo sezindawo ezimnyama, kanti ama-Mana Carriers akhona ngesimo sempunga, okuncike ngomehluko wobukhulu be-elektroni. Esithombeni sakwa-HRTEM nge-10% CO / MA (Fig. 4b), i-Agglomeration ye-CO Metal Izinhlayiya ibonwa ku-Ma Carriers yezengezwa kweRare Ends Personar inciphisa izinhlayiya ze-11.5nm ~ 12.5nm. I-YCCO / MA inokuxhumana okuqinile kwe-co-MA, futhi ukusebenza kwayo kwesono kungcono kunamanye ama-catalysts. Ngaphezu kwalokho, njengoba kukhonjisiwe kumakhiwane. I-4B kuya ku-4F, i-Carbon Nanomawires (CNF) ikhiqizwa kuma-catalysts, axhumana nokugeleza kwegesi futhi avikele i-catalyst kusuka ekusebenzeni.

I-Fig. 3 umphumela wokungezelwa komhlaba okungavamile kwezakhiwo zomzimba nangamakhemikhali kanye nokusebenza kwe-MDR Catalytic kwe-CO / MA Catalyst

3.2.2 I-Deoxidation Catalyst

I-FE2O3 / Meso-Caal, i-De-Doped De-feed De-Dehyystst, yalungiswa ngama-dehydrogenation we-oxidative of 1- lento nge-comas soft oxidant, futhi yasetshenziswa ku-synthesis ye-1,3- buthadieene (BD). I-CE yahlakazwa kakhulu e-Alumina Matrix, futhi i-FE2O3 / MESO yayihlakazeka kakhulu2o3 / Meso-Ceal-100 Catalyst hhayi kuphela izinhlobo zensimbi ezihlakazekile kakhulu futhi zinesilinganiso esihle se-adsorpy, ngakho-ke inekhono elihle le-adsorption kanye ne-activation umthamo we-CO2. Njengoba kukhonjisiwe kuMdwebo 5, izithombe ze-tem zibonisa ukuthi i-FE2O3 / Meso-Coual-100 iSONARTIT ibonisa ukuthi ukwakheka kwesiteshi se-Mesm-100 kuyinzuzo ekusakazweni kwezithako ezisebenzayo, kanti i-PORSOSS EYENZIWE kakhulu CE idonswa ngempumelelo e-Alumina Matrix. Umhlangano wezinto ezibonakalayo zensimbi ezihlekisayo ze-catalyst ezihlangene i-Ultra-Low Emission Standard yezimoto ithuthukise isakhiwo se-pore, ukuqina okuhle kwe-hydrothermal kanye nomthamo omkhulu wokugcina oxygen.

3.2.3 I-Catalyst yezimoto

I-PD-RATEPET I-Quaternary Aluminium Aluminium Esuselwa Emhlabeni Izakhiwo Ezingajwayelekile I-ALCEZRTIOX ne-Allazrtiox ukuthola izinto zokuhlangana ze-catalyst catalyst. I-PD-RH / ALC / ALC / ALC / ALC / ALC / ALC / ALC / ALC / ALC / ALC / i-ALC isetshenziswa ngempumelelo njenge-CNG motor motor persociation Permiation Clialyst ngokuqina okuhle, kanye nokuguqulwa kwe-CH4, okuphezulu kwe-CNG motor audity audic audic audios gesi, kuphakeme njenge-97.8%. I-Adopt Indlela eyodwa ye-hydrothermal ukulungiselela lowo mhlaba ongavamile mandla wokuzihlanganisa ukuze uqaphele ukuzibandakanya, futhi i-synthesis ye-re-all yahlanganiswa, ngakho-ke ukuguqulwa kwe-rejectizelwe, ngakho-ke ukwakheka kokuphelelwa yisikhathi kwe-catalytic egcwele izinto ezintathu.

I-Fig. 4 izithombe ze-HRTEM ze-MA (a), CO / MA (B), i-Laco / Ma (c), i-CCO / C), YCCO / E) ne-SMCO / MA (F) ne-SMCO / MA (F) ne-SMCO / MA (F)

Fig. 5 I-Tem Image (a) ne-EDS Element Diagram (B, C) ye-FE2O3 / Meso-CEAL-100

3.3 ukusebenza okukhanyayo

Ama-elektroni wezinto zomhlaba ezingandile ajabule kalula ekuguqukeni phakathi kwamazinga ahlukene wamandla nokukhanya okukhanyayo. I-Rare Eon i-Ion ivame ukusetshenziswa njengezingenzi zokulungiselela izinto zokwakha ama-luminescent. I-ARRARE YAMANYE I-EMUS ingalayishwa ebusweni be-aluminium phosphate microsches nge-coprecipitation indlela kanye nendlela yokushintshanisa i-ini, kanye nezinto zokwakha ama-luminescent alpo4:re (la, CE, i-ND) ingalungiswa. I-laveleng ye-luminescent iseduze kwesifunda saseduze kwe-ultraviolet.A yenziwa ngamafilimu amancanyana ngenxa ye-inertia yayo, amadivaysi aphansi aphansi futhi anciphise, amafilimu, njll. Kungasetjenziswa ekuboneni amakristalu enhlanganisela eyodwa-turmatic, isizukulwane samandla nezimbambo zokulwa nokubhala. Lawa madivayisi afakwe amafilimu ahlanganisiwe ngobude obuqondile bendlela, ngakho-ke kuyadingeka ukulawula inkomba eyenziwe nobukhulu. Uhla lwezinto zokutholakala kwezinto ezinezinto ezahlukene zamakhemikhali ezingaphezulu zinwetshwa, okwenza kube nokwenzeka ukuklama izinzwa ze-Photon ezithuthukisiwe. Ukwethulwa kwamafilimu we-MA ne-Oxyhydroxide ekwakhiweni kwamadivayisi abonakalayo kukhombisa amandla amakhulu ngoba inkomba eyedlulayo iyafana ne-silicon dioxide.kodwa.

3.4 ukuqina okushisayo

Ngokwanda kokushisa, ukoniwa kuthinta kakhulu umphumela wokusetshenziswa kwe-MaCalystst, kanti indawo ethile engaphezulu yehla kanye ne-γ-al2o3in crystalline isigaba siguqukele ku-δ no-θ kuya kwezigaba. Izinto zomhlaba ezingandile zinokuqina okuhle kwamakhemikhali nokuqina okushisayo, ukuzivumelanisa nezimo okuphezulu, kanye nezinto zokwakha ezishibhile nezishibhile. Ukungezwa kwezinto zomhlaba ezingandile kungathuthukisa ukuqina okushisayo, ukumelana nokushisa okungama-oxidation averation kanye nezakhiwo zemishini zesithwali, bese ulungisa i-acidity ye-carrier.la ne-CE izinto zokuguqulwa ezisetshenziswa kakhulu futhi ezifundwayo. UL Weiguang nabanye bathola ukuthi ukungezwa kwezinto zomhlaba ezingandile zivimbele ukufakwa kwezinhlayiya ngobuningi be-alumina, i-CE kanye ne-ecopting kanye nezolimo zesigaba, futhi kunciphise ukulimala kokushisa okuphezulu kwesakhiwo esihle. I-alumina elungiselelwe isenendawo ethile ephezulu yendawo kanye nevolumu ye-pore. Li Yangqiu et al. Kungezwe ama-5% la2o3to γ-al2o3, owathuthukisa ukuqina okushisayo futhi wandisa ivolumu ye-pore kanye nendawo ethize yendawo ye-alumina. Njengoba kungabonakala kusuka kuMfanekiso 6, iLa2o3Added to γ-al2o3, ithuthukise ukuzinza okushisayo komhlaba onqabile womhlaba.

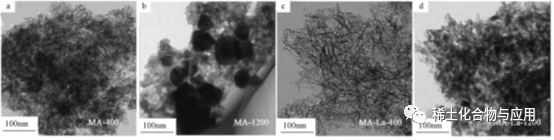

Enqubweni yokuthola izinhlayiya ze-nano-fibrous nge-LA To Ma, indawo yokubheja kanye nevolumu ye-pore ye-ma-la iphakeme kunaleyo ye-ma. njengoba kukhonjisiwe ku-Fig. 7, ngokwanda kwamazinga okushisa, i-LA ivimbela ukusabela kokukhula okusanhlamvu nokuguqulwa kwesigaba, kuyilapho amakhiwane. I-7A ne-7C ikhombisa ukunqwabelana kwezinhlayiya ze-nano-fibrous. ku-Fig. I-7b, ububanzi bezinhlayiya ezinkulu ezikhiqizwa yi-calconation ngo-1200 ℃ imayelana ne-100nm.it imaka isono elibalulekile le-MA. Ngaphezu kwalokho, uma kuqhathaniswa neMa-1200, iMa-La-1200 ayihlanganisi ngemuva kokwelashwa okushisa. Ngokungezwa kwe-LA, izinhlayiya ze-nano-fiber zinekhono elingcono le-isono. Ngisho nasezingeni lokushisa eliphakeme le-cartenation, i-DOPED LA isahlakazwa kakhulu endaweni ye-MA. I-LA Modified Ma ingasetshenziswa njengenkampani yenethiwekhi ye-PD Catalyst ekuphenduleni kwe-C3h8oxidation.

Fig. 6 Imodeli yesakhiwo yesono i-alumina futhi ngaphandle kwezinto zomhlaba ezingavamile

Umdwebo 7 Ama-Phem Izithombe ze-Ma-400 (a), Ma-1200 (b), Ma-La-400 (c) noMa-La-1200 (D)

4 Isiphetho

Intuthuko yokulungiselela kanye nohlelo lokusebenza olusebenzayo lwe-Rare Earth Modified Materied Materies. I-MARE EART Earth MA isetshenziswa kabanzi. Yize ucwaningo oluningi selwenziwe ngohlelo lokusebenza lwe-catalytic, ukuqina okushisayo kanye ne-adsorption, izinto eziningi zinezindleko eziphakeme, inani eliphansi le-doping, i-oda eliphansi futhi kunzima ukuthuthuka. Lo msebenzi olandelayo udinga ukwenziwa ngokuzayo: Lungiselela ukwakheka kanye nokwakheka kwe-Rare Earth Modified Ma, ukhethe inqubo efanelekile, hlangana nentuthuko yokusebenza; Sungula imodeli yokulawula inqubo esekelwe kwinqubo yokusebenza ukunciphisa izindleko futhi uqaphele ukukhiqizwa kwezimboni; Ukuze bandise izinzuzo ze-China ezinqabeni zomhlaba ezivamile, kufanele sihlole indlela yokuguqulwa komhlaba okungavamile, sithuthukise umbono kanye nenqubo yokulungiselela umhlaba ongavamile oguquliwe Ma.

I-Fund Project: SHAANXI Science ne-Technology Yonke imininingwane emisha (2011TDZ01-04-01); Isifundazwe seShaanxi 2019 iphrojekthi ekhethekile yocwaningo lwesayensi (19JK0490); I-2020 Iphrojekthi Ekhethekile Yocwaningo Lesayensi Le-Huaqing College, XI 'Inyuvesi of Architecture neTekhnoloji (20ky02)

Umthombo: Umhlaba ongavamile

Isikhathi sePosi: Jun-15-2021