Ukusetshenziswa kweUmhlaba ongavamileNgokuphonsa i-aluminium alloy yenziwa kwangaphambilini kwaphesheya. Yize iChina yaqala ucwaningo nokusetshenziswa kwalesi sici kuphela ngawo-1960s kuphela, iye yathuthuka ngokushesha. Umsebenzi omningi wenziwe kusuka ekucwaningweni komshini kuhlelo lokusebenza olusebenzayo, kanti ezinye izimpumelelo zenziwe.Izengezwa kwezinto eziwusizo zomhlaba, izinkambu ze-Aluminium, zidla izimo ezibalulekile ekwenzeni izinto ezingenakuqhathaniswa zomhlaba zikhanye Izinto zokwakha, izinto ezivamile zomhlaba ze-hydrogen, njll.

Indlela yokwenza isenzo somhlaba ongandile e-aluminium ne-aluminium alloy ◆ ◆

Umhlaba ongavamile unomsebenzi ophakeme wamakhemikhali, ilungiselelo eliphansi futhi elikhethekile le-elekthroni electron, futhi lingasebenzisana cishe nazo zonke izinto.Rare Ezasezandleni ezisetshenziswa kakhulu ku-aluminium kanye ne-aluminium Alloys zibandakanya uLa (uhlobo linthanum), CE (umrintshi), Y (ytttrium) no-sc (ikhentiyamu). Zivame ukungezwa ngoketshezi lwe-aluminium ngama-modifiers, ama-ejenti athulisa kanye nama-degassing agents, angahlanza ukuncibilika, athuthukise ukwakheka, njll.

01Ukuhlanzwa komhlaba ongavamile

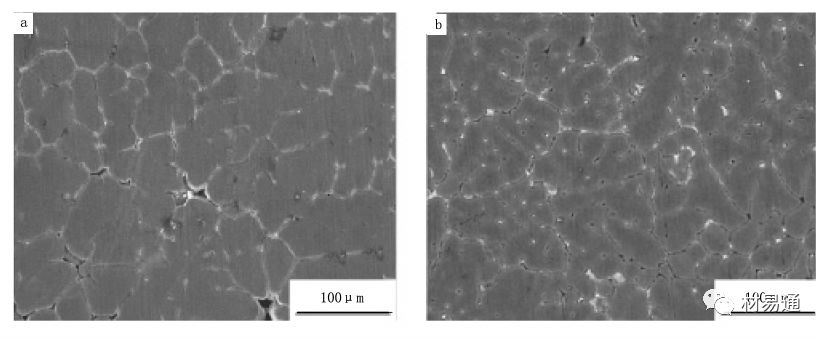

Njengenani elikhulu le-gesi kanye ne-oxide inclusions (ikakhulukazi i-hydrogen, i-oxygen kanye ne-nitrogen) kuzolethwa ngesikhathi sokuncibilika nokukhonkotha kwe-aluminium alloy, kuncibilika ama-aluminium alloy. I-Aluminium, ukuncishiswa kwesilinganiso sePinhole kanye ne-Polosity (bheka umfanekiso 1b), kanye nokwehliswa kwe-hydrogen ngobuhlobo obukhulu kanye nokwandisa kakhulu okuqukethwe kwe-hydrogen kanye nomoya we-aluminium; umhlaba we-nitrogen Amakhompiyutha okuzenzakalelayo, asuswe kakhulu ngendlela ye-slag enqubweni yokushintshana, ukuze afinyelele inhloso yokuhlanza uketshezi lwe-aluminium.

Ukuzijwayeza kufakazele ukuthi umhlaba ongavamile unomphumela wokunciphisa okuqukethwe kwe-hydrogen, umoya-mpilo kanye nesibabule e-aluminium kanye ne-aluminium alloys. Ukungeza i-0.1% ~ 0.3% Re in aluminium uketshezi kuyasiza ukususa ukungcola okulimazayo, ukuguqula ukungcola kwawo noma ukuguqulwa, futhi kungahle kusabalalisekile nge-point point acting amafomu, okukhona, futhi kungashaywa izakhiwo zamakhemikhali, ngaleyo ndlela ukuhlanza uketshezi lwe-aluminium; izinhlayiya ezinhle ezisele ziba yi-nuclei ye-aluminium ukuze ucwengeke.

Fig. 1 sem morphology ka-7075 alloy ngaphandle kwe-re and w (re) = 0.3%

a. I-Re angezwa; b. Faka w (re) = 0.3%

02I-MetamorPhism of Rare Earth

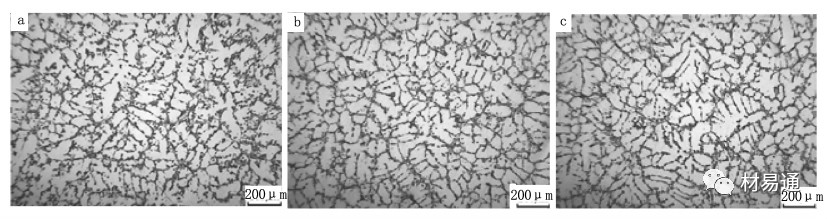

Ukuguqulwa komhlaba komhlaba kubonakaliswa ikakhulukazi ekutholeni okusanhlamvu nama-dendrites, kuvimbela ukuvela kwesigaba esikhulu se-lamellar T2, ukuqeda isigaba se-comples esisatshalaliswa kakhulu (bheka umfanekiso we-athomu lomhlaba wonke, Futhi izakhiwo zayo zisebenza. Ukuncibilika uketshezi lwe-aluminium kulula kakhulu ukugcwalisa amaphutha angaphezulu esigaba se-alloy, okunciphisa ukungezwani okubonakalayo esixhumeni phakathi kwezigaba ezintsha kanye ne-molton

Umdwebo 2

a. Umthamo we-RE ngu-0; b. Ukwengeza kabusha kungu-0.3%; c. Ukwengeza kwere kungu-0.7%

Ngemuva kokungeza izinto zomhlaba ezingandile ze-amentments lwe (al) esigabeni (al) esigabeni saqala ukuba mncane, odlale indima ekwandisene nosayizi omncane we (al) Kuphela uma kugcinwa ekushiseni okuphezulu isikhathi esithile, umhlaba ongavamile uzodlala indima enkulu kunazo zonke kwi-metamorphism.Ukuqhuma kwe-talstal komhlaba kukhuphuka kakhulu lapho umhlaba we-allow uphakamisa kakhulu lapho i-alstal ye-alloy itholakele i-Aluminium Alloy.

03 Umphumela we-microallooling womhlaba ongavamile

Umhlaba ongavamile ukhona ikakhulukazi e-Aluminium nase-Aluminium Alloys ngamafomu amathathu: isixazululo esiqinile ku-matringer (al) umngcele we-aluminium ikakhulukazi afaka phakathi ukuqinisekiswa kokusanhlamvu kwe-aluminium

Uhlobo lokuba khona komhlaba olungavamile emhlabeni e-aluminium kanye ne-aluminium alloy luhlobene kakhulu nenani layo lokungezwa. Ngokuvamile, lapho okuqukethwe kwe-RE kungaphansi kwe-0,1%, iqhaza le-RE ngokukhethekile eliqinisa ukuqina okusanhlamvu kanye ne-RECRITICT ~ 0,30% Imiphumela emincane ehlanganisiwe efana nesigaba sesibili esiqinisayo.

◆ ◆ Umphumela Womhlaba ongavamile kwizakhiwo ze-aluminium ne-aluminium alloy ◆+:

01 Umphumela womhlaba ongavamile ezindaweni eziphelele zemishini ze-alloy

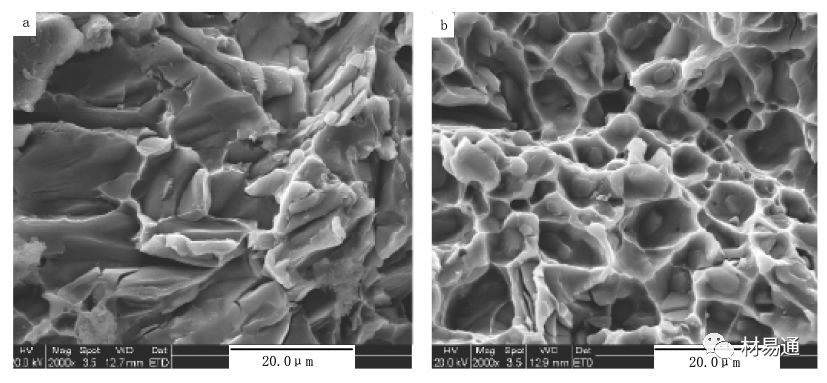

Amandla, ubulukhuni, ukugcwala, ubulukhuni, ukumelana nezinye izakhiwo zemishini ze-alloy zingathuthukiswa ngokungeza inani elifanele lomhlaba ongavamile .0.3% Re.bKusuka ku-205.9 MPA kuya ku-274 MPA, kanye ne-HB kusuka ku-80 kuye ku-108; engeza u-0.42% SC kuya ku-7005 alloyσbkunyuswe kusuka ku-314MPA kuya ku-414MPA, σ0.2kukhuphuke kusuka ku-282mpa kuya ku-378MPA, ipulasitiki inyuke ukusuka ku-6.8% kuye ku-10.1%, futhi ukuqina okushisa okuphezulu kwathuthukiswa kakhulu; Ukungeza i-0.14% ~ 0.64% alloy e-Al-6mg-0.5mn ikhulisa i-superplasticity kusuka ku-430% kuya ku-800% ~ 1000% ~ I-3 ikhombisa ukubukeka kwe-sem kokuqhekeka okuthe xaxa kwe-al-si7-mg0.8I-Alloy, ekhombisa ukuthi ingukuphazamiseka okujwayelekile kwe-cleavage ngaphandle kwe-RE, kuyilapho kufakwa i-0.3% ye-RIMLE, isakhiwo esibonakalayo esibonakalayo sivela ekuqhekekeni okusobala kuvela ekuqhekekeni, okubonisa ukuthi kunobunzima obuhle ne-computer.

Fig. 3 Tensile Fracture Morphology

a. Ayijoyina i-re; b. Engeza u-0.3% Re

02Umphumela womhlaba ongavamile ezindaweni zokushisa eziphakeme zama-alloys

Ukungeza inani elithile leUmhlaba ongavamilee-aluminium alloy angathuthukisa ngempumelelo ukumelana nokuvimbela i-oxidation okuphezulu kwe-aluminium alloy.Adding 1% ~ 1.5% ama-aloy ahlanganisiwe e-Alcon Al Eutectic inyuka ama-all aphezulu, ukuqina kokushisa okuphezulu kanye nokuqina kokushisa okuphezulu kwathuthukiswa kakhulu; I-CU Alloys ingathuthukisa izakhiwo ezishisa kakhulu zama-alloys; i-al-all-8.4% CE Alloy ingasebenza isikhathi eside ngaphansi kwama-400 ℃, ithuthukisa kakhulu izinga lokushisa le-aluminium alloy; sc ingezwe ku-al mg.3Izinhlayiya ze-SC akulula ukuzishisa okuphezulu nokukhombaneni nge-matrix ukufaka umngcele wokusanhlamvu, ukuze i-allioy igcinwe isakhiwo esingahleliwe ngesikhathi sokuncibilikisa, futhi sithuthukisa kakhulu izici zokushisa eziphakeme ze-alloy.

03 Umphumela Womhlaba Ongavamile Ezakhiweni ze-Optical of Alloys

Ukungeza Umhlaba Ongavamile ku-Aluminium Alloy kungashintsha ukwakheka kwefilimu yayo ye-oxide ye-oxide, okwenza ukuthi iphrofayili ye-aluminium inezelwe ku-Aluminium Alloy Alloy, lapho i-alloy ~ 0.3% ithola ukuqeda okuhle kakhulu.

04 Umphumela womhlaba ongavamile ezindaweni zikagesi ze-alloys

Ukungeza i-Aluminium ebumsulwa ephezulu kuyingozi ekuphathweni kwe-alloy, kepha ukuhanjiswa kungathuthukiswa ngezinga elithile ngokungeza i-aluminium elihlanzekile le-aluminium ne-ALTTRION Ukuvuselelwa kwe-alloy, eye yamukelwe amafektri amaningi we-wire yasekhaya; engeza umkhondo uMhlaba ongavamile kwi-aluminium ebumsulwa. Uma isetshenziswa emikhiqizweni engu-25KV, inkomba yeCapacitance iphindwe kabili, umthamo ngamunye wevolumu inyuswa ngamahlandla ama-5, isisindo sehliswa ngo-47%, futhi ivolumu yeCapacitor incishiswa kakhulu.

05Umphumela womhlaba ongavamile ekumelaneni nokugqwala kwe-alloy

Ezindaweni ezithile zensizakalo, ikakhulukazi phambi kwe-chloride ion, ama-alloys asengozini yokugqwala, ukugqwala kwe-crevice, ukugcwala kwengcindezelo kanye nokukhathala kokugqwala.Izenzo zokwenza ngcono. Kutholakale ukuthi ngengeza inani elifanele lomhlaba ongandile ku-Aluminium Alloys lingathuthukisa ngempumelelo ukumelana kwabo nokugqwala. Imiphumela ikhombisa ukuthi ukwengeza inani elincane lomhlaba elingandile ku-aluminium kungathuthukisa ukumelana nokugqwayiza kwamanzi oku-brine kanye ne-32% ifilimu elingaphezulu kwe-aluminium (LA, CE% Ifilimu lokuguqulwa komhlaba elingaphezulu I-2024 Alloy, okwenza ukuthi amandla e-electrode angenayo e-Aluminium Alloy athambekele ekuvulekeni, futhi athuthukise ukumelana nokugqwala okuphezulu kanye ne-aluminion alloy, angeze i-Aluminium Alloys angathuthukisa ukusebenza okuphezulu, ukuqina komoya kanye nokuphikiswa kokugqwala kwe ama-alloys, asetshenziswa kabanzi njengezinto zokwakha ama-aerospace.

Ubuchwepheshe bokulungiselela ◆ I-Aluminium Aluminium alloy ◆ ◆

Umhlaba ongavamile ungezwe kakhulu ngesimo sokulandela izinto ezilandelwayo kuma-aluminium alloys namanye ama-alloys. Umhlaba ongavamile unomsebenzi ophakeme wamakhemikhali, iphuzu eliphezulu lokuncibilika, futhi kulula ukufakwa oxidised futhi ushiswe emazingeni okushisa aphezulu. Lokhu kudale ubunzima obuthile lapho kulungiselelwa futhi kusetshenziswa umhlaba we-Aluminium Alloys.in Ucwaningo lwesikhathi eside lokuhlola, izindlela zokukhiqiza eziphambili zokulungiselela i-Aluminium Alloys ye-Aluminium.at, indlela ekhanyayo kasawoti kanye nendlela yokuncipha kwe-aluminimic.

01 Indlela yokuxuba

Indlela ehlanganisiwe yokuncibilikisa ukwengeza umhlaba ongavamile noma insimbi yomhlaba exubile ibe yi-aluminium yokushisa i-aluminium ngesilinganiso sokwenza i-alloy master noma i-alloy esetshenzisiwe ngokwesibonelelo esiseduze, ivuse ngokuphelele futhi icwenge.

02 I-electrolysis

Indlela ye-electrolysis ye-molten ukwengeza i-rare Earth Ort noma umhlaba usawoti we-electolytic cell kanye ne-electrolze nge-aluminium oxide ukukhiqiza umhlaba we-aluminium allecle.molten stal.molten stal.molten stal.molten stal.molten stal.molten stal.molten stal.molten stal.molten stat electrolysis indlela iye yathuthukiswa ngokushesha eChina. Ngokuvamile, kunezindlela ezimbili, okungukuthi, indlela ye-cathode eluhlaza kanye nendlela ye-electrolytic eutectoid. Njengamanje, kwakhiwe ukuthi amakhompiyutha omhlaba angavamile angezelwe ngqo kumaseli we-aluminial alectrolytic we-aluminium, kanti ama-alloy ase-Aluminium angavamile akhiqizwa nge-electroride ye-chloride incike ngendlela ye-eutectoid.

03 Indlela yokunciphisa i-Aluminithermic

Ngoba i-aluminium inekhono lokunciphisa eliqinile, futhi i-aluminium ingakha amakhompiyutha ahlukahlukene okuphakathi nendawo komhlaba, i-aluminium ingasetshenziswa njenge-ejenti yokunciphisa ukulungiselela umhlaba we-aluminium alloys.

RE2O3+ 6. → 2Real2+ Al2O3

Phakathi kwazo, umhlaba ongavamile we-oxide noma umhlaba ongenasisekelo uSlag ocebile ungasetshenziswa njengezinto zokwakha zomhlaba ezingandile; i-ejenti yokunciphisa ingaba yi-aluminium evuthayo noma i-aluminium ye-fluential, eminyakeni yamuva nje izobangela izinkinga eziningi; indlela yokunciphisa i-aluminic. Emazingeni aphansi aphansi (780 ℃), ukusabela kokuncishiswa kwe-aluminimic sekuqediwe ohlelweni lwe-sodium fluoride kanye ne-sodium chloride, okugwema izinkinga ezibangelwa ukushisa okuphezulu okuphezulu.

◆ ◆ inqubekela phambili yesicelo seRare Earth aluminium alloy ◆ ◆

01 Ukusetshenziswa kweRare Earth Aluminium Alloy embonini yamandla

Ngenxa yezinzuzo zokuvuselelwa okuhle, umthamo omkhulu wamanje, amandla aphezulu, ukumelana nokudla okulula, i-aluminium ye-aluminium ye-Aluminium, okuyi-aluminium alloy angakwazi ukuthuthukisa i-aluminium alloy into enokungcola okuphezulu Okuqukethwe, okunomthelela omkhulu kwizakhiwo zikagesi. Ukungeza inani elifanele lomhlaba ongavamile kungathuthukisa i-morphology ekhona kanye nokusatshalaliswa kwe-silicon ku-alloy, okungathuthukisa ngempumelelo indawo efanelekile ye-aluminium noma i-yttrium eqondisiwe emhlabeni Uhlelo lwe-Aluminium Alloy. Izintambo kanye nabaqhubi benziwe nge-Aluminium Alloy engavamile bangakhulisa isikhathi se-cable tower futhi bandise impilo yenkonzo yezintambo.

02Ukusetshenziswa kweRare Earth Aluminium Alloy embonini yezokwakha

I-Aluminium Alloy yiyona esetshenziswa kakhulu embonini yezokwakha. Ukungeza i-0.15% ~ 0.25% Umhlaba Ore Umhlaba ungathuthukisa kakhulu isakhiwo kanye nesakhiwo sokulungisa, futhi kungavimbela ukusebenza kwe-aluminion, imingcele yokwelashwa kanye ne-increndritic ye-aluminitic, futhi kuchithwe amakhompiyutha noma akhona Ngokwezinkomba zokucwilisa isakhiwo se-dendrite kanye okusanhlamvu, ngakho-ke usayizi we-eutectic ongavuthiwe nosayizi we-dimple ndawo uba mncane kakhulu, futhi ukwabiwa kuyakhuphuka, ukuze ama-density ahlukahlukene athuthukiswa, ukuze kukhuphuke ukwanda kwe-alceli. Isibonelo, amandla wephrofayili inyuke ngaphezu kwama-20%, ukunwebeka kukhuphuka ngo-50%, futhi isilinganiso sefilimu exide sikhuphuka ngo-5% ~ 8%, futhi i-Re-6063 Alloy wokwakha amaphrofayli asetshenziswa kabanzi.

03Ukusetshenziswa kwe-Aluminium Aluminium alloy nsuku zonke

Ukungeza Ukulandela Umhlaba Ongavamile Ku-Aluminium Emsulwa kanye ne-Al Mg Series Aluminium Alloys for Daily I-Aluminium Imikhiqizo ye-Aluminium ingathuthukisa kakhulu izimbiza ze-aluminium, ama-aluminium amabhasikidi, izingxenye ze-aluminium, nezingxenye ze-aluminium, nezingxenye ze-aluminium zasekhaya ezenziwe nge-al mg re I-Alloy inokuphikiswa okuphindwe kabili kokuphindwe kabili, ukuncishiswa kwesisindo okungu-10% ~ 15%, okungu-10%

04 Ukusetshenziswa kweRare Earth Aluminium Alloy kwezinye izici

Ukungeza izinkulungwane ezimbalwa zomhlaba ongandile e-Alloy esetshenziswa kakhulu ye-Al SI CECICE kungathuthukisa kakhulu ukusebenza kwemishini ye-alloy. Izinhlobo eziningi zemikhiqizo zisetshenzisiwe endizeni, imikhumbi, izimoto, izinjini zezimoto, izithuthuthu, ibhokisi le-armored (isilinda kanye ne-SC yinto ephumelela kunazo zonke yokwenza ukwakheka nezakhiwo ze-aluminium alloys. Inokuqiniswa okuqinile kokusakazwa, ukuqinisekiswa kokuhlwaya okuqinisa, isixazululo sokuqinisa kanye nemiphumela yokuqinisa ama-microallsoy kwi-aluminies, futhi kungathuthukisa amandla, izitimela eziphakeme, izimoto ezisheshayo, izimoto ezikhanyayo, njll .c557l MG ZR Sc series scandium aluminum alloy developed by NASA has high strength and high temperature and low temperature stability and has been applied to aircraft fuselage and aircraft structural parts;The 0146Al Cu Li Sc alloy developed by Russia has been applied to the cryogenic fuel tank of spacecraft.

Kusuka kuMvovo 33, khipha 1 kokungayilayi umhlaba nguWang Hui, Yang An qi

Isikhathi sePosi: Jul-05-2023