Yini ithonya lomhlaba ongandile oxides egqoke izimbobo ze-ceramic?

I-Ceramics, izinto zensimbi nezinto zokwenziwa kwama-polymer zibhalwe njengezinto ezintathu ezinkulu eziqinile. I-Ceramic inezakhiwo eziningi ezinhle kakhulu, njengokumelana nokushisa okuphezulu, ukumelana nokugqwala, ukuphefumula, njll. Ukuhlanganiswa kwe-Ceramic kungashintsha ukubukeka, ukwakheka kanye nokwenza kwendawo yangaphandle ye-substrate, composite ye-coating-substrate iyathandwa ukusebenza kwayo okusha. Kungahlanganisa kahle izici zoqobo ze-substrate ngezimpawu zokumelana okuphezulu, ukumelana okuphezulu nokuphikiswa okuphezulu kwezinto zokwakha, ngakho-ke kudlale ngokugcwele ezinhlotsheni ezimbili zezinto zokwakha, ngakho-ke kusetshenziswa kakhulu embonini yamakhemikhali kanye nezinye izimboni.

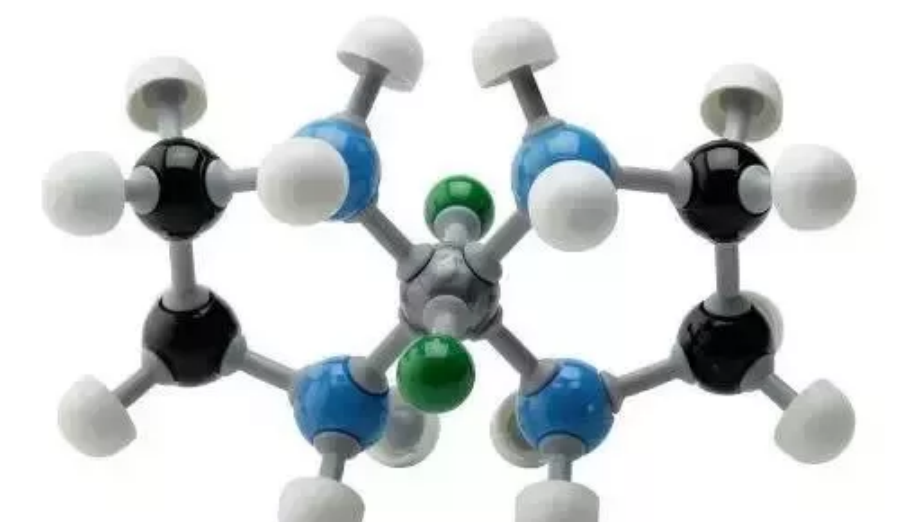

Umhlaba ongavamile ubizwa ngokuthi "Indlu Yamagugu" yezinto ezintsha, ngenxa yesakhiwo sayo se-4F esiyingqayizivele se-4F kanye nezakhiwo zenyama nezamakhemikhali. Kodwa-ke, izinsimbi zomhlaba ezihlanzekile ezingandile azivame ukusetshenziswa ngokuqondile ocwaningweni, futhi amakhompiyutha omhlaba angavamile asetshenziswa kakhulu. Amakhompiyutha ajwayelekile kakhulu yi-CEO2, iLa2o3, Y2O3, i-LO'O3, i-CEF, CES kanye neRare Earth Ferrosilicon.Lala amakhompiyutha omhlaba angavamile angathuthukisa ukwakheka nezakhiwo zezinto zokwenziwa kwe-ceramic kanye nezingubo ze-ceramic.

Ngisebenza nge-Rare Earth oxides ngezinto zokwenziwa kwe-ceramic

Ukungeza izinto zomhlaba ezingandile njengabezokugcina kanye nezinsizakusebenza ze-ceramics ezihlukile kunganciphisa amazinga okushisa wesono, kuthuthukise amandla nokuqina kwama-ceramics athile wesakhiwo, futhi ngaleyo ndlela kunciphise izindleko zokukhiqiza. Ngasikhathi sinye, izinto zomhlaba ezingavamile nazo zidlala indima ebaluleke kakhulu ezinzwa ze-semiconductor, imithombo yezindaba ye-microwave, ama-ceramonics we-piezoelectric namanye ama-ceramics asebenzayo. Ucwaningo luthole ukuthi, engeza umhlaba owodwa noma ngaphezulu onqabile emhlabeni oxides ku-Alumina ceramics ndawonye kungcono kunokungeza umhlaba oyedwa ongavamile oxide e-Alumina ceramics. Ngemuva kokuhlolwa kokusebenza kahle, i-CEO ye-Y2O3 + inomphumela omuhle kakhulu. Lapho u-0.2% y2o3 + 0.2% CEQEO2 ungezwa ngo-1490 ℃, ubuningi obuhlobene namasampula ane-mince angafinyelela ku-96.2%, odlula ubuningi bezinsalela y2o2 noma i-CEO2 yedwa.

Umphumela weLa2o3 + Y2O3, i-SM2O3 + LA2O3 ekuthuthukiseni i-Soconing ingcono kunaleyo yokufaka iLa2o3, futhi ukumelana nokugqoka kusobala. Kubonisa nokuthi ukuxutshwa komhlaba amabili angajwayelekile oxides akukhona ukwengeza okulula, kepha kukhona ukuxhumana phakathi kwawo, okuzuzisa ukwenziwa ngcono kwe-Alumina Ceramics, kepha umgomo uhlala ufundwe.

Ngaphezu kwalokho, kutholakala ukuthi ukungezwa kwezinkomba ezihlanganisiwe zomhlaba ezihlanganisiwe njengezinsiza-zesono kungathuthukisa ukufuduka kwezinto zokwakha, ukukhuthaza ukona kwezinto zokwakha futhi kuthuthukise ubuntu. Kodwa-ke, lapho okuqukethwe kwe-oxide yensimbi ehlanganisiwe kungaphezu kwe-15%, ubuningi obuhlobene buyancipha futhi i-porolity evulekile yanda.

Okwesibili, ithonya lomhlaba ongandile oxides ezindaweni zokumbona kwe-ceramic

Ucwaningo olukhona lukhombisa ukuthi izinto zomhlaba ezingavamile zingacwilisa usayizi wokusanhlamvu, zikhuphule ubungako, zithuthukise i-misccucture futhi zihlanze isikhombimsebenzisi. Idlala indima eyingqayizivele ekuthuthukiseni amandla, ubulukhuni, ubulukhuni, ukugqokwa kokuphefumula kanye nokuphikiswa kokugqwala kwezingubo zobumba ze-ceramic, ezithuthukisa ukusebenza kwezimbozo ze-ceramic ngezinga elithile.

1

Ukuthuthukiswa Kwezakhiwo Zemishini Yezembatho Ze-Ceramic nge-Rare Earth oxides

Ama-oxide anqabile emhlabeni angathuthuka kakhulu ngobunzima, ukubopha amandla namandla okubopha ama-tensaile wezimbali ze-ceramic. Imiphumela yokuhlola ikhombisa ukuthi amandla ashubile e-coating angathuthukiswa ngempumelelo ngokusebenzisa i-LAO _ 2 njenge-Tio e-LAO 2_ 2 i-6.0%. Ukungeza i-CEO2 ngengxenyana enkulu ye-3.0% no-6.0% ku-CR2O3 okuqukethwe, amandla ashukumisayo aphakathi kwe-12 ~

2

Ukuphuculwa kokumelana nokushaqeka okushisayo kokuhlanganiswa kwe-ceramic ngombala ongavamile

Ukuhlolwa kokumelana nokushaqeka okushisayo kungukuhlola okubalulekile kukhombisa amandla okubopha phakathi kwama-coating kanye ne-substrate kanye nokufana kokukhishwa kwemali okushisayo okuphakathi nendawo kanye ne-substrate. Ibonisa ngqo ikhono lokuhlanganisa ukumelana nokukhonkotha lapho izinga lokushisa lishintsha ngokusetshenziswa ngesikhathi sokusebenzisa, futhi libonisa nekhono lokukhomba ukuze limelane noMeshini oshaqisayo kusuka ohlangothini.

Ucwaningo lukhombisa ukuthi ukwengeza i-3.0% CEO2 kunganciphisa i-porosity nosayizi we-pore ku-coating, futhi kunciphise ukugxila kwengcindezi emaphethelweni ama-pores, ngaleyo ndlela kuthuthukise ukumelana nokushaqeka kwe-CR2O3. Kodwa-ke, i-polosion ye-Al2o3 Curamic Coagic yehle, kanye namandla e-bonding kanye nokuhluleka ukwehluleka okushisayo kwempilo ye-coating kwanda ngokusobala ngemuva kokungeza iLao2. Lapho inani le-Lao2 le-Lao2 lingama-6% (ingxenyana enkulu), ukumelana nokushaqeka okushisayo kwe-coati kuhamba phambili, futhi impilo yokwehluleka okushisayo ingafinyelela izikhathi zokuphamba ezingama-218, kanti i-thermal yehluleka ukwehluleka impilo ye-coapor ngaphandle kwezikhathi ezingama-163.

3

I-Rare Earth Oxides ithinta ukumelana kokugqoka kwezimbozo

Emhlabeni ongavamile oxides esetshenziselwa ukuthuthukisa ukumelana nokugqokwa kwe-ceramic coatings ikakhulukazi i-CEO2 neLa2o3. Isakhiwo sabo se-hexagonal esibunjiwe singakhombisa umsebenzi omuhle wokuthambisa futhi silondoloze izakhiwo zamakhemikhali ezinzile ekushiseni okuphezulu, okungathuthukisa ngempumelelo ukumelana nokugqokwa futhi kunciphise ukungqubuzana kwezezimali.

Ucwaningo lukhombisa ukuthi ukungqubuzana kokungqubuzana kokuhlanganiswa kwenani elifanelekile le-CEO2 lincane futhi lizinzile. Kubikwa ukuthi ukufaka iLa2o3 kuya ku-Plasma efafazwe i-cermet esuselwa ku-cermet coating kungavimbela ukugqokwa kwezingxabano kanye nokuphazamiseka kokuhlanganiswa kwemali ehlanganayo, kanye ne-coefflent engxabanweni iqinile yokushintshashintshamba. Ingaphezulu le-Clad of Cladding ungqimba ngaphandle komhlaba ongavamile libonisa ukunamathela okungathi sína nokuphazamiseka, noma kunjalo, ukunamathela okuqukethe umhlaba ongenasisekelo kukhombisa ukunamathela okubuthakathaka. I-microssmcture of raistrud e-Doped Coating iyinqwaba futhi ikhokheke ngokwengeziwe, futhi ama-pores ancishisiwe, anciphise ukungqubuzana kwenxenye yomhlaba futhi kuholela ekushintsheni kwebanga le-cermets, kuholela ekushintsheni kwamandla okusebenzisana phakathi kobuso obubili be-crystal futhi kunciphisa ukungqubuzana kwe-coeffection.

Isifinyezo:

Yize ama-oxide e-Rare Earth Earth enza impumelelo enkulu ekusetshenzisweni kwezinto zokwakha ubumba kanye nezimbobo, ezingathuthukisa ngempumelelo izakhiwo ze-ceramic kanye nezingubo zokugqoka.

I-TELE: + 86-21-20970332Ivangeli:info@shxlchem.com

Isikhathi sePosi: Sep-02-2021