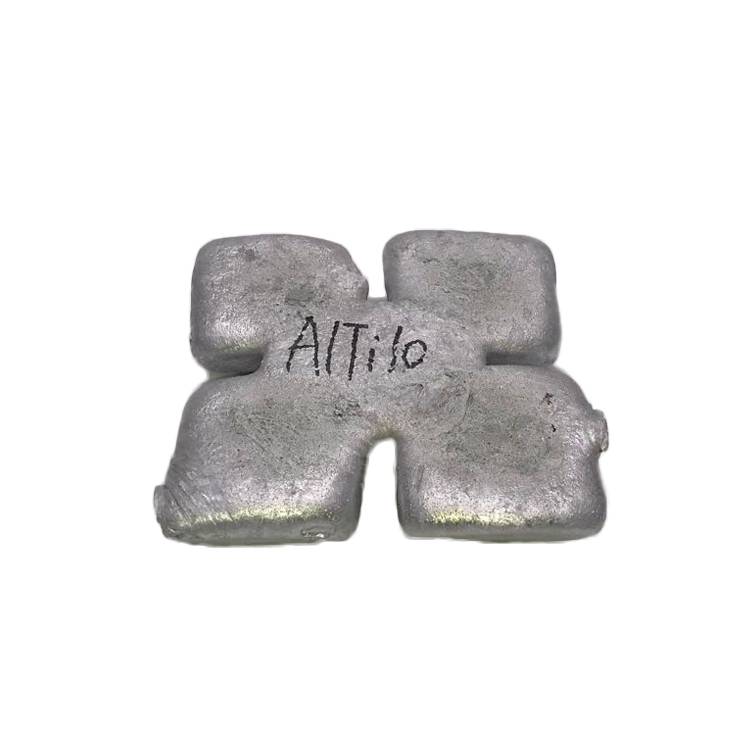

Alti10 comtot aluminium Master alloy

Alti10 insut Almumium Titanium Master alloy

Master alloys bụ ngwaahịa emechara, ma enwere ike ịmepụta ya n'ụdị dị iche iche. Ha bụ tupu ngwakọta a na-ahụ maka ihe ị na-eme. A makwaara ha dị ka ihe sinapị, isi, ma ọ bụ ndị na-edozi ọka dabere na ngwa ha. A na-agbakwunye ha na gbazee iji nweta nsonaazụ a jọgburu onwe ya. A na-eji ha na-eji ya kama igwe dị ọcha n'ihi na ha nwere akụ na ụba ma chekwaa ume na oge mmepụta oge.

Aha Ahịa:Almumium Titanium Master alloy

Ndebiri:Al-Tiye Master alloy

Aha ndi ozo: aluminium ukwu alloy, aluminium ukwu alloy, Alti Master Alloy

Ọdịnaya:Alti10

Melting Point: 1020-1070 ° C

Formdị: slab, waffle, cankụt, lumps, wdg

| Aha | Aluminium tetaniumMaster Alloy | ||||||||||||||||

| Standadi | GB / T276777-2011 | ||||||||||||||||

| Ndinaya | Ngwakọta kemịkal ≤% | ||||||||||||||||

| Itule | Si | Fe | Cu | Mn | Cr | Ni | Ti | B | V | Zn | Pb | Sn | Mg | C | Otu ozo | Ngụkọta adịghị adị | |

| Alti3 | Al | 0.30 | 0.35 | / | / | / | / | 2.5 ~ 3.5 | / | / | / | / | / | / | / | 0.05 | 0.15 |

| Alti4 | Al | 0.20 | 0.30 | / | / | / | / | 3.5 ~ 4.5 | / | / | 0.10 | / | / | / | / | 0.05 | 0.15 |

| Alti5 | Al | 0.50 | 0.45 | 0.15 | 0.35 | 0.10 | 0.10 | 4.5 ~ 5.5 | / | 0.25 | 0.15 | 0.10 | 0.10 | 0.50 | / | 0.05 | 0.15 |

| Alti6 | Al | 0.30 | 0.35 | / | / | / | / | 5.5 ~ 6.5 | 0.004 | 0.30 | / | / | / | / | / | 0.03 | 0.10 |

| Alti10 | Al | 0.30 | 0.35 | / | / | / | 0.05 | 9.0 ~ 11.0 | 0.004 | 0.50 | / | / | / | / | / | 0.03 | 0.10 |

| Alti6a | Al | 0.20 | 0.20 | / | / | / | / | 5.5 ~ 6.5 | 0.004 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti10a | Al | 0.20 | 0.20 | / | / | / | 0.05 | 9.0 ~ 11.0 | 0.004 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti12 | Al | 0.30 | 0.30 | / | / | 0.10 | 0.10 | 11.0 ~ 13.0 | / | 0.50 | / | / | 0.10 | / | / | 0.10 | 0.15 |

| Alti15 | Al | 0.30 | 0.30 | / | / | 0.15 | 0.15 | 14.0 ~ 16.0 | / | 0.50 | / | / | 0.15 | / | / | 0.10 | 0.15 |

| Alti3b1 | Al | 0.20 | 0.30 | / | / | / | / | 2.8 ~ 3.4 | 0.7 ~ 1.1 | / | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.2 | Al | 0.30 | 0.35 | / | / | / | / | 4.5 ~ 5.5 | 0.15 ~ 0.25 | 0.25 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.2a | Al | 0.15 | 0.20 | / | / | / | / | 4.5 ~ 5.5 | 0.15 ~ 0.25 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.2B | Al | 0.30 | 0.40 | / | / | / | / | 4.5 ~ 5.5 | 0.1 ~ 0.5 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.6a | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0,5 ~ 0.7 | / | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b0.6 | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0,5 ~ 0.7 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b1 | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.8 ~ 1.2 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b1A | Al | 0.15 | 0.20 | / | / | / | / | 4.8 ~ 5.2 | 0.9 ~ 1.1 | 0.05 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b1B | Al | 0.20 | 0.25 | / | / | / | / | 4.5 ~ 5.5 | 0.8 ~ 1.2 | 0.10 | / | / | / | / | / | 0.03 | 0.10 |

| Alti5b1c | Al | 0.20 | 0.30 | / | / | / | / | 4.5 ~ 5.5 | 0.4 ~ 1.2 | 0.20 | / | / | / | / | / | 0.03 | 0.10 |

| Alti3c0.15a | Al | 0.20 | 0.20 | / | / | / | / | 2.6 ~ 3.4 | 0.004 | 0.05 | / | / | / | / | 0.08 ~ 0.22 | 0.03 | 0.10 |

| Alti3c0.15 | Al | 0.30 | 0.15 | / | / | / | / | 2.6 ~ 3.4 | 0.004 | 0.30 | / | / | / | / | 0.08 ~ 0.22 | 0.03 | 0.10 |

| Alti3c0.3 | Al | 0.20 | 0.20 | / | / | / | / | 2.6 ~ 3.4 | 0.004 | 0.05 | / | / | / | / | 0.25 ~ 0.35 | 0.03 | 0.10 |

| Ngwa | 1 2. Achịcha ọka: ejiri ya maka ịchịkwa mgbasa nke kristal na ọla iji mepụta ihe ọkaibe na ndị ọzọ edo edo. 3. Mgbanwe & alloys pụrụ iche: na-ejikarị mmụba ike, itinye aka na ngwa na ngwa. | ||||||||||||||||

| Ngwaahịa ndị ọzọ | Umi,Alti,Alo,Agwọ,Alosr,Alzr,Alka,Alli,Alre,Alcu, Alcr,AlQ, ALRE,Mwa,Abu, Mmanya,Almo, Alw,Omeo Alg, Alzn, Alsn,Ace,Itali,Anana, Alpr, Alnd, Alyb,Alo, wdg. | ||||||||||||||||

Asambodo:

Ihe anyi puru inye: