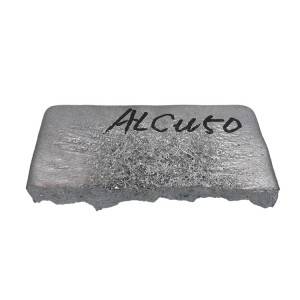

Calper calcium cru-ca Master Alloy Cuca20 Metal ingots

Ọla kọpa calcium Master alloy Cuca30 Cuca20Metal na

Calper-calcium Master alloyA na-eji ya emepụta ihe dị iche iche. A na-eme Master Alloy site na ijikọ ọla kọpa na calcium na oke (ọ na-abụkarịCuca20Ma ọ bụ Cuca30) iji nweta ihe ndị achọrọ na njiri mara maka otu ngwa.

Calper-calcium Master HarloysA na-eji ọtụtụ ebe emepụta ọla kọpa na alloys ya n'ihi ike ha iji melite akụrụngwa ndị ahụ na ngwaahịa nke ikpeazụ ngwaahịa. A maara ya maka ezigbo dexidiption ya na akụrụngwa dị mma, ị na-enyere aka ịkwalite ogo nke ihe ndị dabeere. Ọzọkwa, ịgbakwunye calcium na ọla kọpa na-eme ka ọ dị mma na eletriki, na-eme ka ọ dị mma maka ngwa na ụlọ ọrụ eletriki na ụlọ ọrụ eletrik.

Otu n'ime uru isi nke iji aCalper-calcium Master alloybụ ikike iji belata ego mmepụta ahụ n'ozuzu ya. Site na ịgbakwunye ọkaibe Alloy na ọla kọpa na-agbaze, oriri nke calcium dị ọcha na ọla kọpa nwere ike belata, si otú a na-echekwa ụgwọ ọrụ. Na mgbakwunye, iji Master Alloys na-agba mbọ ka ukwuu na nke na-edoghị anya ihe ị na-ekenye ihe na ngwaahịa ikpeazụ, si otú a na-agbanwe agbanwe na ịdị mma.

Na nkeCalper-calcium Master HarloysNa-eme ka ha dị ọcha maka ụdị ngwa, gụnyere mmepụta nke eriri eletrik, ihe eji eme ihe na akụkụ dị iche iche. Ma ọ na-abawanye ike na ịdịgide nkeCoverper alloyma ma ọ bụ na-eme ka eletriki eletrik ha, mgbakwunye nkeCalper-calcium Master Harloysna-eweta ọtụtụ abamuru na ụlọ ọrụ na-arụpụta ihe.

| Ọla kọpa calcium Master alloy | |||||||

| Ndinaya | Cuca2030 ma ọ bụ ahaziri | ||||||

| Ngwa | 1 2. Achịcha ọka: ejiri ya maka ịchịkwa mgbasa nke kristal na ọla iji mepụta ihe ọkaibe na ndị ọzọ edo edo. 3. Mgbanwe & alloys pụrụ iche: na-ejikarị mmụba ike, itinye aka na ngwa na ngwa. | ||||||

| Ngwaahịa ndị ọzọ | Cub, cumg, cusi, cusi,Iko, Curi, Cuz, cuni,Ka cucr, Cufu, GECU,Sias, Mpako, Cuzr, Cusb, mara mma, Cula,Stiu, CUP, CUSM, Cubi, wdg. | ||||||