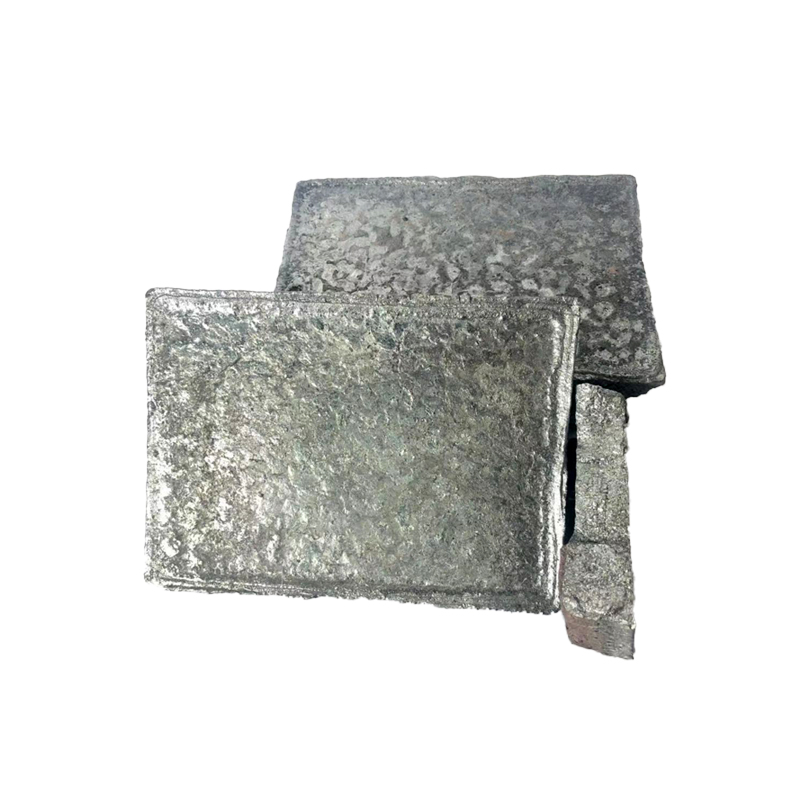

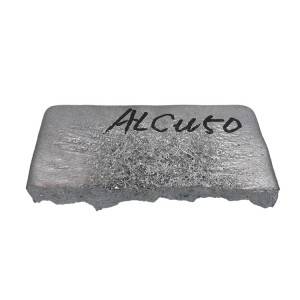

Ọla kọpa phosphorus ukwu alloy cup14 alloy

Master alloys bụ ngwaahịa emechara, ma enwere ike ịmepụta ya n'ụdị dị iche iche. Ha bụ tupu ngwakọta a na-ahụ maka ihe ị na-eme. A makwaara ha dị ka ihe sinapị, isi, ma ọ bụ ndị na-edozi ọka dabere na ngwa ha. A na-agbakwunye ha na gbazee iji nweta nsonaazụ a jọgburu onwe ya. A na-eji ha na-eji ya kama igwe dị ọcha n'ihi na ha nwere akụ na ụba ma chekwaa ume na oge mmepụta oge.

| Aha | Phosphorus ọla kọpa Master Alloy | ||

| Ndinaya | Ngwakọta kemịkal ≤% | ||

| Itule | P | Fe | |

| Cup Cup14 | Cu | 13 ~ 15 | 0.15 |

| Ngwa | 1 2. Achịcha ọka: ejiri ya maka ịchịkwa mgbasa nke kristal na ọla iji mepụta ihe ọkaibe na ndị ọzọ edo edo. 3. Mgbanwe & alloys pụrụ iche: na-ejikarị mmụba ike, itinye aka na ngwa na ngwa. | ||

| Ngwaahịa ndị ọzọ | Cub, cumg, cusi, iko, cuble, cufu, cud, cund, cund, cund, cubi, cubi. | ||

Arụmọrụ na ojiji

Ngwaahịa a bụPhosper phospros nke ọla kọpanwere 13.0-15.0% phosphorus, nke ejiri maka mgbakwunye nke ihe ọkụkụ nke phosphorusCoverper alloyna-eme m. Ihe mgbakwunye ahụ dị ala na nchịkwa nchịkọta ziri ezi ziri ezi.

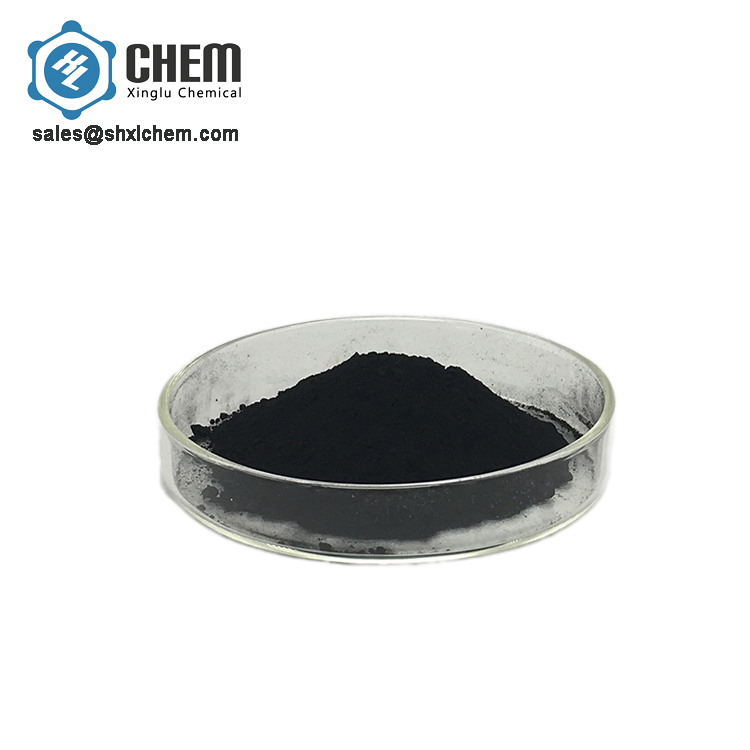

Ojiji

Gbakọọ ọdịnaya nke phosphorus kwesịrị ịgbakwunye, mgbe mmiri ọla kọpa gbazee, tinye ọla kọpa ọla kọpa frosphorus alloy. Kpoo nke ọma ma jikọta ọnụkea, kwesịrị ekwesị maka ịgbakwunye ego trace nke phosphorus. N'ihi oke ikuku nke phosphorus ntụ ntụ na mgbawa, ọ dị mkpa iji hazie ya n'ime ọla kọpa na-etiti alpoyloy na-aga n'ihu, wee jiri ya maka mgbakwunye. Nke a abụghị naanị nchekwa na gburugburu ebe obibi, kamakwa ọ na-eji otu mejupụtara. Ọbụghị naanị na enwere ike iji ya dị ka ihe mgbakwunye, mana ọ nwekwara ike wepu gas na oxygen.