N'etiti oxigis na-ezighi ezi, alumina nwere ezigbo ihe eji arụ ọrụ, mpaghara dị elu na-eguzogide, nke dị ka ihe na-egbochi ya, dị ka crackion, na-achịkwa ya A na-ejikarị alumina na ụlọ ọrụ, mana ọ ga-emetụta ọrụ nke alimina, ndụ ndụ na uru nke ihe na-akpata. Dịka ọmụmaatụ, na usoro ịdị ọcha nke ahịhịa, na-etinye mmetọ site na ihe mgbakwunye mmanụ ga-etolite, nke ga-eduga ngọngọ nke ihe omimi. Enwere ike iji sọffant nwere ike ijikwa ihe owuwu nke Alumina Carries iji mepụta ma.imrove arụmọrụ ya.

Mbinye ihe mgbochi, na ọla ndị na-arụ ọrụ na-agbaze mgbe ike na-aga cartlọ ọrụ dị elu. Na mgbakwunye, mgbe eriri ọnọdụ dị elu gasịrị, ihe owuwu dị elu dapụtara, ọkpụkpụ nke dị na Amorphous State, na elu acidity enweghị ike iru ihe ndị ọ chọrọ n'ọhịa. A na-achọkarị ọgwụgwọ mgbanwe ahụ, nkwụsi ike na-ahụkarị, na-emegharị emegharị (na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na) Ma ọ bụ tinye n'ime ọkpụkpụ.

Nhazi elektrọn pụrụ iche nke ihe dị egwu n'ụwa nwere ngwa ọrụ anya ya, eletriki na ihe dị iche iche, ihe eji eme ihe na ihe osise foto. A na-ahụkarị ihe onwunwe ụwa na-ahụ anya, na-abawanye ma ọlị. Na mpempe akwụkwọ a, a ga-ewebata ọnọdụ ụwa nke ma ọ bụrụ na a ga-eme ka ọ dịkwuo mma maka arụmọrụ caritytic, ike ikuku, ebe a kapịrị ọnụ dị elu na nke pore.

1 Ma Nkwadebe

Mmalite 1.1 nke Alumina Carriety

Thezọ nkwadebe nke alumina na-ekpebi nkesa ihe owuwu ya, ụzọ mgbapụ ya na-agụnye pseudo-Bohydzọ na sol-gel. Pseudobot (PB) nke Calvet chọrọ nke Calvet, na H + na-akwalite nkwarụ na-enweta γ-alooh colloida, nke e nwere mmiri na-acha odo odo, nke a na-ejikọ ya na oke okpomọkụ iji mepụta alumina. According to different raw materials, it is often divided into precipitation method, carbonization method and alcoholaluminum hydrolysis method.The colloidal solubility of PB is affected by crystallinity, and it is optimized with the increase of crystallinity, and is also affected by operating process parameters.

A na-akwadokarị PB site na usoro na-apụta. A na-etinye na alkali na-agbakwunye ya na ngwọta alumina site na ngwọta alumina site na nledo alumina na-eme ka ọ nweta Alumina Elumina Monohydrate, nke a na-asa ma nwee ike inweta PB. A na-adịkarị mfe ịrụ ọrụ na ala na-akwụ ụgwọ, nke a na-ejikarị na mmepụta ọrụ, mana ọ na-emetụta ọtụtụ ihe (ọnọdụ ahụ, wdg). Na carbonatization usoro, al (oh) nke 3is nwetara site na mmeghachi omume nke co2and Neo2, na PB nwere ike nweta mgbe ị na-akakpa ọrụ. Usoro a nwere uru dị na ọrụ dị mfe, ogo ngwaahịa dị elu, enweghị mmetọ na ala dị ala, ma nwee ike ịkwadebe Alumina nwere ọtụtụ ihe ndị dị elu na elu na-abụkarị iji kwadebe pb. Aluminium alkoxide bụ hdrolyzed iji mepụta aluminom oxide monohydrate, nke nwere ezigbo kristal, nke nwere uru na-esize nha na-eguzosi ike n'ezi ihe. Agbanyeghị, usoro ahụ siri ike, ọ na-esi ike iweghachi n'ihi iji ụfọdụ ihe mgbaze na-egbu egbu.

Na mgbakwunye, a na-ejikarị nnu ma ọ bụ mmanụ nje na-akwadebe ihe ndị na-eme ka usoro Alumina, na mmiri na-agbakwunye na-edozi sol iji mepụta sol, nke a na-agbanye ma na-acha uhie uhie. Ka ọ dị ugbu a, usoro nkwadebe nke Alumina na-eme ka ntọala nke usoro akụ na ụba nke SB-Gel kwadebere ya, nke bụ usoro enwere ike ịbawanye ngwa nke ụlọ ọrụ.

1.2 ma Nkwadebe

Okeluna enweghị ike iru ihe ndị na-arụ ọrụ, yabụ ọ dị mkpa ịkwadebe arụmọrụ dị elu ma. Methoszọ njikọ njikọ njikọ na-agụnye: usoro nano-nkedo na carbon bus ka e temple; Sypesis nke SDA: Enyemaka nke ime nzukọ (Eisa) na ọnụnọ nke ndebiri dị nro dịka SDA na ndị ọzọ anion ma ọ bụ anaghị arụ ọrụ.

1.2.1 EISA usoro

A na-eji Template dị nro na ọnọdụ acidic, nke na-ezere usoro dị mgbagwoju anya na oge na-ewe oge siri ike ma nwee ike ịghọta ngbanwe na-aga n'ihu. Nkwadebe nke ma ọ bụ Eisa dọtara mmasị na ụdị ya dị mfe na ịmụ nwa. Enwere ike ịkwadebe usoro dị iche iche. A na-edozi nha nke ma enwere ike idozi ya site na ịgbanwe otu a na-emegharị anya na ngbanwe nke a na-eme na-eme ihe dị iche iche. Eisa) F127, Trainolamine (tii), wdg eisa nwere ike dochie ihe ndị a na-ebu ụzọ na-eme atụmatụ na p123, maka ịmịpụta ihe na-eme nke ọma. ma kwe ka mmepe nke mesoophases guzobere site na micless micless na sol.

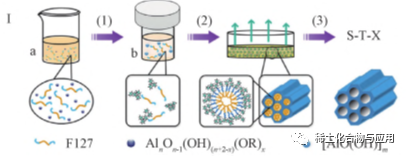

Na usoro eisa, ihe ndị na-abụghị ihe mgbazinye ndị na-abụghị ihe dị ka ethanol) na ọnụego ya na-agbadata na usoro ihe ọ bụla, dị ka al (ma ọ bụ) 3Acpoxigide. Agbanyeghị, na sọmọkụ na-adịghị agbanwe agbanwe, ndebiri Sootactates na-ejikarị hydrophicty / hydrophobity. Na mgbakwunye, n'ihi igbu oge nke hydrolysis na polyconsenesse, ngwaahịa etiti nwere hydrophobic otu, nke na-eme ka o sie ike na templent spret. Naanị mgbe ịta nke sọks na ogo nke hydrolysis na polyconsenssation nke aluminom mụbaa na usoro nke nhọta nke ihe mgbapụta nwere ike imepụta ihe na-egbu egbu nwere ike imepụta otu ndebiri na aluminom. Ya mere, ọtụtụ paramemeters na-emetụta ọnọdụ nsị nke mgbaze na mmeghachi omume nke ndị na-emepụta ihe, dị ka ọnọdụ okpomọkụ, iru mmiri, wdg., Wdg ga-emetụta nhazi ikpeazụ. Dị ka egosiri na fig. 1, ihe eji akwụsi ike na arụmọrụ dị elu na-arụ ọrụ dị elu site na sistemụ solvothesmal enyere aka na mgbakọ onwe onye (sa-eisa). Usoro ọgwụgwọ solvottal na-akwalite hydrolysis prest zuru ezu nke aluminom na-etolite di iche iche a na-etolite difyocy na-eme ka ọ bụrụ Mezagonal Mesagome. Na usoro ọdịnala eisa, usoro evapoly na-esonyere hydrolysis iburgalum bu ụzọ, ya mere, ọnọdụ ndị na-efe efe nwere mmetụta dị mkpa na mmeghachi omume nke Oma. Usoro ọgwụgwọ solvothermal na-akwalite hydrolysis ibu zuru ezu nke aluminom hydroxy hydroxy na-eme ka ọ dị iche iche n'okpuru ọtụtụ ọnọdụ ikuku. E jiri ya tụnyere Maa usoro ọdịnala, OMA kwadebere site na Sa-eisa na-enwe oke olu dị elu, mpaghara elu ka mma na nkwụsi ike ka mma. N'ọdịnihu, enwere ike iji usoro eisa iji kwadebe ultra-nnukwu akụkụ apịtị ma jiri nnukwu mgbanwe na nhọrọ dị oke egwu na-enweghị iji onye na-ahụ maka ihe.

Fig 1 na-asọpụta usoro nke SA-EISA maka Synshending Oma

1.2.2 usoro ndị ọzọ

Mgbakọ ma na-achọ nchịkwa zuru oke nke paramessis iji mezuo ihe owuwu doro anya, yana mwepụ nke ihe ndebiri na-enwekarị usoro. Ka ọ dị ugbu a, ọtụtụ ihe ndetu akọpụtala njikọta nke ma na ndebiri dị iche iche. N'afọ ndị na-adịbeghị anya, nyocha ahụ lekwasịrị anya na njikọta nke ma na glucose na ihe ndị a na-eme bụ ndetu, sulfate na alkoxide dị ka isi mmalite Aluminom. Ma CTAB na-enweta site na mgbanwe nke PB dị ka isi iyi aluminom. Ma na ihe owuwu dị iche iche, ya bụ al2o3) -1, al2o3) -2 na Al2o3 nwere ezigbo nkwụsi ike. Ihe mgbakwunye Surtactant anaghị agbanwe usoro kristal nke PB, kama na-agbanwe ọnọdụ na-ebelata. Na mgbakwunye, e guzobere al2o3-3, a na-akpụzi adhesion nke Nanoparticles na-agba mbọ na-agbaze na nke organic Peg ma ọ bụ nchịkọta gburugburu Peg. Agbanyeghị, nkesa nke al2o3-1 dị warara. Na mgbakwunye, a kwadebere Palladiumsts ma na Syntetic Ma dị ka mmeghachi omume nke Carrier.in na Methone Cold, nke Al2O3-3 gosipụtara arụmọrụ dị mma.

Na nke izizi, ma nwere nke dị larịị nha nkesa dị larịị na-akwado ya site na iji aluminom na aluminom ọgaranya nke aluminom. Usoro imepụta gụnyere usoro mmịpụta na obere okpomọkụ na nrụgide nkịtị. Uru ahụ siri ike na usoro mmịpụta agaghị emerụ gburugburu ebe obibi, enwere ike iji ihe egwu dị ala ma ọ bụ mebie ya. Mpaghara elu nke synhes ma ọ bụ 123 ~ 162m2 / g, nkesa nke dị warara bụ 5.3nm, na porsos bụ 0.37 cm3 / g. Ngwa ahụ bụ nano-sized na crystal nha dị ihe dị ka elekere 11. Njikwa siri ike nke steeti bụ usoro ọhụrụ iji syshes ma, nke enwere ike iji mepụta parchemical mita maka ụlọ ọgwụ. Achịkọta chlorium chlomium, ammonium carbonate na glucose a na-agwakọta ya na merlar nke 1: 1.5, mkpụrụokwu nke na-arụ ọrụ na-eme ihe bụ 90%, na na na na] (1.7TBQ / ml), si otú a mata iji nnukwu dose1311I [Nai] capsules maka ọgwụgwọ ọrịa cancer.

Nchịkọta, n'ọdịniihu, enwere ike ịmepụta obere molecular na-arụ ọrụ na-arụ ọrụ, na-agbanwe ihe owuwu, ma mepụta nnukwu mpaghara ma nyefee wormhole Ma. Nyochaa ndebiri na isi mmalite aluminium, na-ebuli usoro njikọ, kọwapụta usoro njikọ ma na-eduzi usoro ahụ.

Usoro mgbanwe nke 2 ma

Ofzọ nke ekenye iche na-ekesa ihe ndị na-arụ ọrụ na ma onye na-eburu ya na-arụ ọrụ, In-Hetiniting, ịgwakọta nke ọma, nke abụọ mbụ a na-ejikarị.

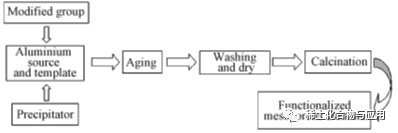

2.1 in-sittu njikọ

A na-agbakwunye otu mgbanwe arụmọrụ na nhazi nke ịkwadebe ma dozie ọkpụkpụ nke ihe ahụ ma melite arụmọrụ. A na-egosipụta usoro a na eserese 2. Liu e et al. Synhenezed Ni / Mo-Al2o3in HATU na P123 dị ka ndebiri. A na-akụsaị abụọ a na-achụsasị ha n'usoro, na-enweghị ibibi ihe owuwu nke Ma, na arụmọrụ ndị ahụ na-arụ ọrụ ka mma. Na-eme usoro uto na-eto eto na-aga n'ihu na gemma3substrate, ma e jiri ya tụnyere γ-al2o3, mno3-al2o3has buru ibu nke nwere ihe eji eme ya site na nkesa nha. MNO2-Al2o3has Akwụ ụgwọ Mgbasa ozi Mgbasa Ozi na arụmọrụ dị elu maka f-, ma nwee ọtụtụ ngwa ph (pH = 4), nke kwesịrị ekwesị maka ọnọdụ ngwa ụlọ ọrụ dị mma. Ighaghachite arụmọrụ nke MNO2-Al2O3I dị mma karịa nke nke γ-al2o.Scirust nke dị mma. Releught na-anakọta, ihe ndị a na-enwetara site na njikọta nke In-sittu nwere ezigbo usoro nhazi, yana ibu dị mfe, yana usoro mmeghachi omume na-arụ ọrụ na usoro mmeghachi omume, yana arụmọrụ na-arụ ọrụ ka mma.

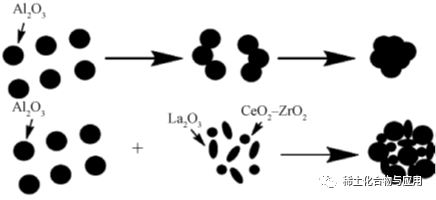

Fig 2 nke nkwadebe nke ma site na njikọta

Endzọ Impregnation 2.2

Ime ka ọ bụrụ ma ọ bụrụ na otu ndị ahụ gbanwetụrụ, ma nweta ihe ndị ahụ gbanwetụrụ mgbe ọgwụgwọ, ka ha ghọta mmetụta nke cataly, onye mgbasa ozi na ihe dị ka. Cai et al. Site na p123 site na Sọs-gel, ma tinye ya na ethanol na Tetraehyleebeentamine iji nweta Amino modere mapị na-arụ ọrụ. Na mgbakwunye, Belkaacemit et al. Debere na zncl2ssotion site n'otu usoro iji nweta aha Zinc doped moded ma ihe. E jiri ya tụnyere usoro njikọta nke dị na-si anọgide, usoro impregning nwere ihe dị mma, na-arụ ọrụ dị mma na arụmọrụ mgbasa ozi na-arụ ọrụ na-adịghị ike, ma na-arụ ọrụ na-enweghị isi site na mpụga.

3 ọganihu

Njikọ nke ụkọ ụwa Ma na Njirimara pụrụ iche bụ mmepe mmepe n'ọdịnihu. Ka ọ dị ugbu a, enwere ụzọ synsis usoro. Usoro usoro usoro emetụta arụmọrụ nke ma. Mpaghara elu a kapịrị ọnụ, olu pore na pore dayameta nke ma enwere ike idozi ya na ụdị ndebiri na usoro ihe mejupụtara aluminom. Ọnọdụ mgbako na polymen ndebiri echiche na-emetụta mpaghara a kapịrị ọnụ dị elu na olu m. Suzuki na Yamauchi chọpụtara na mgbako okpomọkụ ahụ na-aba ụba site na 500 ℃ ruo 900 ℃ .The a nwere ike belata ma belata mpaghara elu. Na mgbakwunye, ọnọdụ mgbanwe elu ụwa na-ahụkarị ka ọrụ ahụ, nkwụsi ike nke na elu acidity nke ma ihe na catalic usoro, ma mezuo mmepe nke arụmọrụ.

3.1 Desluonation Admiason

Flusgba mmiri na mmiri ọ drinkingụ na-a drinkingụ na China bụ ndị na-emerụ ahụ nke ukwuu. Na mgbakwunye, mmụba nke fluorine na-arụ ọrụ na-arụ ọrụ na-eme ihe ga-eduga corrosode nke efere eletrik na mbelata nke usoro ọrụ eletrik na usoro electrolysis na-egbu egbu na-egbu egbu. Ugbu a, usoro mgbasa ozi bụ ihe kachasị mma n'etiti ụzọ mgbochi mmiri na-emebi emebi. Ohere ụfọdụ dị na Mgbasa ozi, dị ka pzọ dị na ya, mgbatị mgbatị ahụ dị warara, na-efe efe na. A na-arụ ọrụ carbon, amorphous arụ ọrụ, a na-arụ ọrụ a niile na-eme ihe na-adịghị ala ala, ma ọ bụrụ na ọ dị elu na-enweghị nsogbu Ike Mgbasa ozi dara ogbenye nke fluoride, ma ọ bụ naanị na pH <6 nwere ike ịdọrọ ezigbo ọrụ na mpaghara ebe obibi nke gburugburu ebe obibi, arụmọrụ acid, arụmọrụ na nkwụsi ike. Kundu et al. Kwadebere ikike nke fluorine nke 62.5 mg / g. Dị ka mpaghara na-ahụ maka mgbasa ozi, dị ka nke na-arụ ọrụ, dị ka nke na-arụ ọrụ nke ukwuu site na njiri mara ya nke ukwuu site na njiri mara ya nke ukwuu. Ebumnuche nke ma ọ bụ nke Ma bụ ụzọ dị mkpa iji mee ka ọrụ Mormarption ya melite arụmọrụ ya.

N'ihi acid nke na-achasi ike nke la na isi ihe siri ike nke fluorine, enwere mmekọ siri ike n'etiti La na Fluorine. N'afọ ndị na-adịbeghị anya, ụfọdụ ọmụmụ achọpụtala na LA dị ka onye na-agbanwe agbanwe nwere ike ime ka ikike mgbasa ozi dị mma. Agbanyeghị, n'ihi nkwụsi ike nke usoro dị ụkọ, n'ihi na a na-emebi ihe dị ụkọ n'ime ya, na-ebute mmetọ mmiri na ihe ọjọọ nye ahụike mmadụ. N'aka nke ọzọ, elu ịta nke aluminom na ebe a na-ahụ maka mmiri bụ otu n'ime olulu ahụ nye ahụike mmadụ. Ya mere, ọ dị mkpa ịkwadebe ụdị usoro mgbasa ozi mejupụtara ya na ezigbo nkwụsi ike na enweghị ịkatọ ihe ndị ọzọ na-eme ka ọ dị. Madebere ya site na La na OA site na OR Impregnition (la / Ma na OA). A na-ejikọkarị ya nke ọma na nke mbụ, nke nwere ọrụ mmeghachi omume dị elu, nke na-arụ ọrụ na-arụ ọrụ na-arụ ọrụ na-ejikọ ya na FLDROGY Ike nke fluorine, la / ma nwere ihe ndị ọzọ na-eme Hydroxyl Shordorp saịtị, na ikike mgbasa ozi nke f dị n'usoro nke LA / Ma> MA. Site na mmụba nke itinye uche nke mbụ, ikike ndị mgbasa ozi nke fluorine na-abawanye. Ọ bụrụ na PHOSORPPEPPEPTETPROM na-enwe usoro fluorine na Langmur IdentirMal ShorptionMall. Na mgbakwunye, adịghị ike nke eons na Alumina nwekwara ike imetụta ogo nke ihe nlere. Ọ bụ ezie na nyocha ndị metụtara ụwa agbanweela, ihe ka ọtụtụ na-elekwasị anya na usoro fluorine na mmegharị nke fluarine nke flulluonation nke zenc sulfate ngwọta na zinc sulfate na zinc sulfate Sistemụ HydromeTulirgy, ma guzosie ike usoro njikwa usoro maka ịgwọ ọrịa dị elu dabere na oke ụwa na-adịghị ahụkebe man nano Addorbent.

3.2 Ihe Nlekọta

3.2.1 Ndozigharị nke methane

Oke ụwa dị ụkọ nwere ike idozi acidity (ihe dị mkpa) nke porous, mmụba oxygen, na synhaze na-enwekarị nkụda mmụọ, nanomome ọnụ na nkwụsi ike. A na-ejikarị ya na-akwado ọla dị mma na mital mgbanwe iji merie methanation nke CO2. Ugbu a, a na-emegharị ụwa niile na-etolite na-etolite methane na-etolite methane, dị ka pdc.), wdg, wdg. ọnụ ahịa nke methane. Agbanyeghị, ebe obibi na carbbon nke ninoparticles n'elu ni / al2o3lead ruo ngbanwe ngwa ngwa nke ihe na-akpata. Ya mere, ọ dị mkpa ịgbanwee ngwa ngwa, gbanwee ụgbọelu ndị na-ebu ihe ma melite ụzọ nkwadebe iji meziwanye ọrụ na-arụ ọrụ, nguzogide na-eguzogide. Na mkpokọta, enwere ike iji ụwa dị iche iche dị ka ihe owuwu na elektrọnik na Heteteogeneous na-eweta mbibi nke NI ma gbanwee Njirimara nke Metallic NI site na mmekọrịta nkwado igwe siri ike.

A na-ejikarị Ma mee ka mgbasa nke ọla, ma na-enye njide nke ọla na-arụ ọrụ iji gbochie agglomeration. La2O3With dị elu nchekwa oxygen oxygen na-eme ka carnon na-eme ka carbon usoro, na La2o3promes na alumina, nke nwere ọrụ ndozigharị na resisụ elu. Ndị La2o3promer na-abawanye MDR na-arụ ọrụ nke CO / MATETTANSTST, na CO3ESTOSTOSTOSTOSS na-etolite na oke ala. Na usoro MDR, na-in-sittu n'etiti La2O3and Co2formed La2O2MeSophase, nke kpachapụrụ anya mkpochapụ cxhy na elu. La2o3promes mbelata site na ịnye njupụta elektrọn dị elu ma na-eme ka oxygen pụọ na 10% CO / MA. Mgbakwunye nke La2o3s nke arụ ọrụ nke Ch4conschi. Ya mere, ntụgharị nke ch4increre na 93.7% na 1073k k. Nkwado nke saịtị na-arụ ọrụ, na-abawanye na-etinye carbon na-arụ ọrụ, mepụtara oghere oxygen na 73.3%.

A na-akwado SER na NI / Al2O3CATALALYS site na usoro dị na nha anya Linaedo. Mgbe ọ na-agbakwunye OD na pr, nhọrọ a na-ahọpụta na nhọrọ iji belata. The MDR na-agbanwe ikike site na phalytic ike, na nhọrọ a na-ahọpụta site na 64.5% ruo 75.6%, ebe nhọrọ ka ọ belata site na 31.4% peng shujing et al. Ejirila usoro gal-gel, nke gbanwetụrụla na AluminoPoxide, ihe mgbaze Isopropanol ma na-aba uru na hexahydte hexahydrate. Mpaghara elu a kapịrị ọnụ nke ngwaahịa ahụ na-abawanye. Ihe mgbakwunye nke ubi ahụ belatara nchịkọta nke mkpanaka na elu ma ọ bụ elu. Cityfọdụ hydroxy dị na elu nke γ- al2o3wer kpuchiri ekpuchi. Ọnọdụ nkwụsi ike nke Mama, ọ nweghị mgbanwe mgbasa kristal mere mgbe ikesi ike na 1000 ℃ ruo 10 awa.wang bawei et al. Ejiri usoro ihe eji eme ihe. CEO2IT Obere ọka cubic na-ejikọkarị na alumina. Mgbe onye isi ala na-akwado CO na CEO2, al2O2, al2O4, mmekorita a n'etiti akụrụngwa Alumina na molọ ọrụ na-arụ ọrụ nke ọma site na CEO2

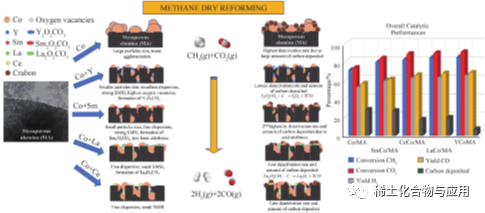

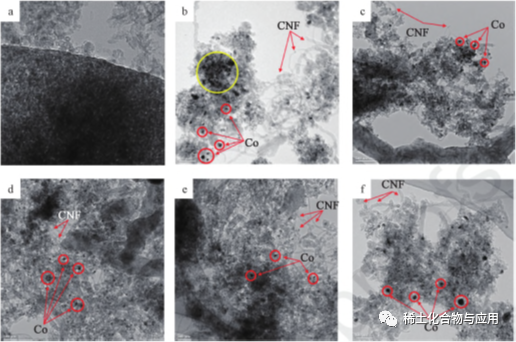

A na-ejikọ ndị na - akwalite ụwa ahụ dị ụkọ (LA, Y na SM) jikọtara ya na CO / MAYTA maka MDR, na usoro ahụ gosipụtara na fig. 3. The a na-eme ka ndị na-eto eto na-eto eto nwere ike melite mgbasa ozi nke CAR na na-ebugharị agglomeration nke cart. Obere urughuru, sie ike na njikọta Co-ma Cattalytic na Ikike na-enweghị atụ, na nsonaazụ dị mma nke ọtụtụ ndị na-eme nkwalite na ntinye ego na carbon. 4 bụ ihe osise HRTEM mgbe MDR na 1023K, CO2: CH4: N2 = 1: 1: 3.1 maka 8 awa. CHOTTST dị n'ụdị nke ojii tụrụ, ebe ndị na-ebu ya dị n'ụdị isi awọ, nke na-adabere na ọdịiche nke elektrọn na-enwe ihe dị iche. Na ihe onyonyo HRTEM na 10% CO / MA (Fig 4B), agglomeration nke ahihia eji eme ihe na-ebelata elu ụwa na-ebelata. Yco / Ma nwere mmekọrịta com-mane, na arụmọrụ ya dị mma karịa ihe ndị ọzọ. Na mgbakwunye, dị ka egosiri na fig. 4b ruo 4f, hullow nanowires (CNF) emepụtawo na camilysts, nke na-eche na gas na-egbochi ihe na-akpata nsogbu.

Fig 3 nke a na-ahụ anya ụwa na akụrụngwa na kemịkalụ na MDRANYTIC arụmọrụ nke CO / MADAYST

3.2.2 DEOXIDAtion Metalityst

Fexi3 / Meso-cell, na-eji akwa mmiri nke na-eme ihe na-atọ ụtọ nke 1- Beene dị nro nke 1- Booddrogen oxidant, ma ejiri ya na njikọta 1,3- Beldiene (BD). A chụsasịrị na Matrix Alumina, na Featto-cealsfu2o3 / Meso-Contayst Ọ bụghị naanị na-agbasasị usoro iron. Dị ka egosiri na eserese 5, Meso-cell-ceal-ceal-ceal na-egosi na ọwa mmiri na-egosi na ọwa mmiri na-egosi, ebe a na-adọsasị nke Escia nke ukwuu na Alumina Matrix. Ihe eji eme ihe eji eme ihe na-eme ka ihe a na-ahụ maka ikuku na-ahụ maka ụgbọ ala na-emepụta ihe owuwu nke ụgbọ ala.

3.2.3 catalyst maka ugbo ala

PD-Rh kwadoro mbara ala a aluminom n'ụwa dị oke njọ Alcezrtiox na Allazrtiox iji nweta ihe mkpuchi akpaghị aka. A na-eme nke ọma ụwa dị egwu PD-RH / Alc / Alc Cars na-eme ka ọ dị ọcha nke chg, na ntụgharị nke CNG ụgbọ ala gas, dị elu dị ka 97.8%. Hapụ usoro nzọụkwụ hoodrdrortal iji kwadebe ihe na-adịghị ahụkebe ụwa, na-eto eto na steeti "Connes na-agbakọta nke a na-ahụ maka ngwa agha nke Automaly Ihe Ntụgharị Ultalytaly.

Fig 4 hrtem nke ma (a), ma (b), laco / ma (c), ceco / ma (ma (e) na amco / ma (f)

Fig 5 (A) na Eds mmewere eserese (b, c) nke Fe2O3 / Meso-ceal-100

3.3 arụ ọrụ

Electrons nke ihe dị egwu n'ụwa na-adị mfe ịgbanwe n'etiti ọkwa dị iche iche na ìhè Emit. A na-ejikarị ya dị ka ndị na-eme ihe dị ka ndị na-eme ihe iji kwadebe ihe ndị dị laminesternt. Enwere ike itinye ikuku ụwa nke aluminom n'elu oghere nke aluminom phospheres na-agbanwe agbanwe site na usoro ngụgụ na usoro mgbanwe, na LA, ST, PR, ND) nwere ike ịkwadebe. A na-eme ka ikuku na-efe efe dị na mpaghara Ultraviolet.ma dị nro n'ihi na njikọta ya, ihe mgbochi, na-eme ihe na-enweghị atụ, ọ ga-eme ka ọ bụrụ nke na-ahụ maka circy circlels, ọgbọ na mkpuchi ikuku. A na-ejikarị ihe nkiri ndị a dị ogologo, yabụ ọ dị mkpa ijikwa index index na ọkpụrụkpụ, Titanium dioxium na silicon dionide na-ejikarị index dị ala iji chepụta ma wuo ụdị ngwaọrụ ndị ahụ. A na-enweta ọtụtụ ihe dị iche iche kemịkal dị iche iche a na-agbasa, nke na-eme ka ọ kwe omume imewe phondọm dị elu. Mmeghe nke ihe nkiri Maxydydydydydydroxide na-egosi nnukwu ihe ngosi n'ihi na ntinye uche dị ukwuu dị ka nke si silicon dioxide.but akụrụngwa kemịkal dị iche.

3.4 nkwụsi ike

Site na mmụba nke okpomọkụ, ebe obibi na-emetụta nsonaazụ nke Matalysts, mpaghara a kapịrị ọnụ na-ebelata na γ-al2O3in na-agbanwe n'ime Δ na θ nke. Ọdịda ụwa na-akwụsi ike nke ukwuu na nkwụsi ike ikuku, ime mgbanwe dị elu, ma dị mfe na akụrụngwa dị mfe. Ihe mgbakwunye ụwa na-adịghị ahụkebe nwere ike melite nkwụsi ike ọkụ ahụ, okpomoku okpomọkụ na-eguzogide na akụrụngwa nke ụgbọ mmiri, ma na-emegharị elu acidity nke na-ebu ya ma na-amụ ihe ndị a na-agbanwe. Lu wedaag na ndị ọzọ chọpụtara na mgbakwunye nke ihe dị ụkọ n'ụwa meriri otu dị iche iche nke Alumina, ma belata mmebi nke okpomoku dị elu iji mee ka ọ dị elu. Alumina kwadebere ka mpaghara elu a kapịrị ọnụ nke dị elu ma na-efe efe. Li Onqiu et al. Agbakwunyere 5% la2o3to γ-al2o3, nke mere ka nkwụsi ike na-akwụsi ike ma mụbaa olu pore na mpaghara elu a na-ere ahịa. Dịka enwere ike ịhụ site na ọgụgụ 6, La2o3dded to γ-al2o3, meziwanye nkwụsi ike nke ndị na-ebu ụwa.

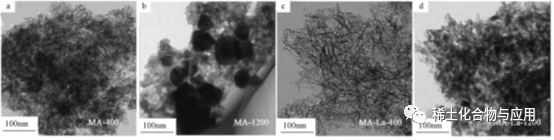

Na usoro itinye aka nano-fibrous nano na la ruo ma, elu elu mpaghara na olu pore nke Ma-LA dị elu karịa nke ma mgbe okpomọkụ na-abawanye na ikpochapụ okpomọkụ dị elu. dị ka egosiri na fig. 7, na mmụba nke okpomọkụ, la na-egbochi mmeghachi omume nke uto na ọganihu, ebe fig. 7A na 7C na-egosi mkpokọta nke nano-fibrous. Na fig. 7b, dayameta nke nnukwu irighiri ihe na 1200 ℃ ihe dị ka 100nm.Ọ na-egosiputa ihe dị iche iche nke ma. Na mgbakwunye, e jiri ya tụnyere Ma-1200, Ma-LA-LA-1200 anaghị achịkọta mgbe a gwọsịrị ọgwụgwọ. Na mgbakwunye nke LA, ihe nano-nano-na-enwe obi ụtọ. Ọbụna na elu mgbakọ dị elu, doped la ka a ka gbasasịrị na elu. Enwere ike iji ma ọlị ma enwere ike iji ya dị ka onye na-ebu PD na mmeghachi omume c3h8oxination.

Fig 6 ụzọ na-emepụta ihe na-egbu egbu na-enweghị ihe ọ bụla

Fig 7 nke ma-400 (a), ma-1200 (b), ma-la-400 (c) na Ma-LE-LE-LET (D)

Mmeghari

Ọganihu nke nkwadebe na itinye ngwa ọrụ nke ihe ndị a na-adịghị ahụkebe ụwa. A na-ejikarị ma gbanwee ụwa. Ọ bụ ezie na emerela ọtụtụ nyocha na ngwa intalytic, oke ikuku, ọtụtụ ihe nwere ọnụ ahịa dị oke ọnụ, ego na-adịghị ike ma sie ike ịbụ ndị mepere emepe. Ọ dị mkpa ka a rụọ ọrụ ndị a n'ọdịnihu: bulie ihe mejupụtara ya na nhazi nke ụwa elu ala, họrọ usoro kwesịrị ekwesị; Mepụta usoro njikwa usoro dabere na usoro arụmọrụ iji belata ụgwọ ọrụ na ịghọta mmepụta mmepụta ihe; Iji mee ka uru ụwa nke China dị ụkọ, anyị kwesịrị inyocha usoro nke oke ụwa nke ụwa, meziwanye echiche na usoro nke ịkwadebe ụwa dị ụkọ ma.

Ihe omume ego: Shianxi Science na Teknụzụ Kacha Nzuzo (2011ktdz01-04-01); Shaanxi Messical 2019 Ọrụ Njem Omume Ọhụrụ (19jk0490); 2020 oru ngo nyocha nke sayensi nke Huaqing College, XI 'Mahadum nke ulo oru na teknụzụ (20KY2))

Isi Iyi: Ala Dị Ubi

Oge post: Jun-15-2021