Ọla kọpa filperna-eketa ihe na-ahụ maka ọla kọpa dị mma nke ọla kọpa, na-eme ya n'ọtụtụ ebe n'ọtụtụ injinụ eletriki na eletriki

N'ime ọtụtụ ihe, ọla kọpa cha cha abụrụla kpakpando na-enwu enwu na ụlọ ọrụ mmepụta ihe n'ihi ihe ndị pụrụ iche na ngwa.

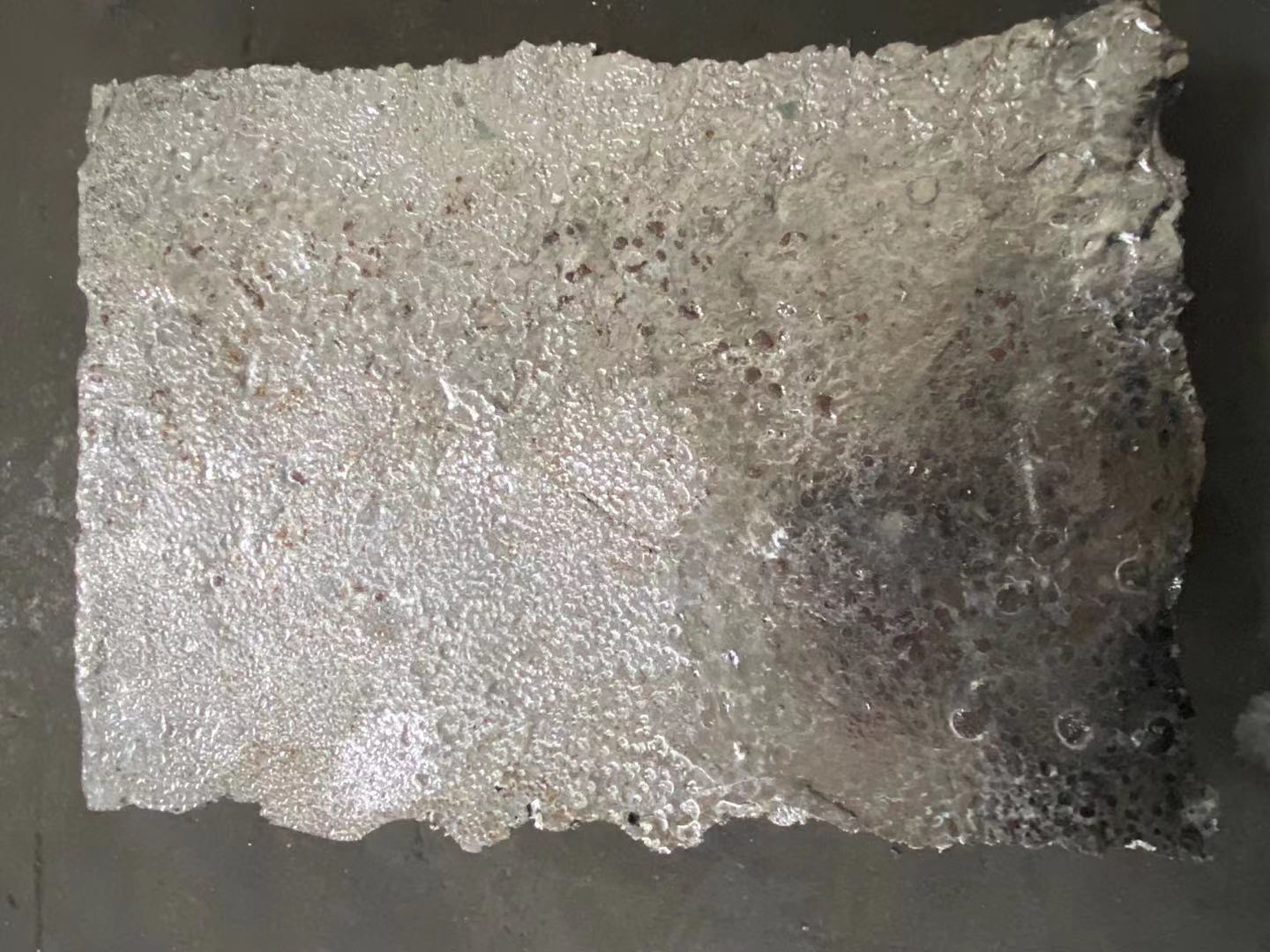

1, njirimara nke ọla kọpa phosphorus

1. Ezigbo echiche na nkụchi egwu

Ọla kọpa phosphorusInweta omume ọla kọpa kachasị mma, na-eme ka ha jiri ọtụtụ ndị injinịa eletriki na igwe eletriki. Ma ọ bụ eriri na eriri, ihe eji ele eletriki, ma ọ bụ akwụkwọ nyocha, ọla kọpa na-arụ ọrụ dị mma

2. Ezigbo nguzogide

Ọla kọpa filperNwere ezigbo nguzogide na-eguzogide ma nwee ike iguzogide mbuzi mgbasa ozi dị iche iche. Mpempe akwụkwọ ọla kọpa nwere ike ịnọgide na-arụ ọrụ kwụsiri ike ma gbasaa ndụ ọrụ ha na iru mmiri, acidic, gburugburu alkaline.

3. Ezigbo Nhazi

Filper phosphorus alloY nwere ezigbo ọrụ ma nwee ike hazie ya n'ime ụdị dị iche iche site na ịgbaghara, na-agagharị, na-agbatị na usoro nhazi ndị ọzọ. Nhazi nhazi ya dị elu karịa ọtụtụ ihe ọ bụla, na-enye ihe dị mma maka imepụta na n'ichepụta.

4.. Ike dị elu na isi ike

Site na idozi ọdịnaya nke Phosphorus na teknụzụ nhazi, ọla kọpa phosphorus nwere ike nweta ike na isi ike. Nke a na-eme ka ọ rụọ ọrụ nke ọma ebe ọ dị mkpa idugide nnukwu ibu ma na-eyi, dịka sistem, ndị na-arụ ọrụ, wdg.

, Ngwa nke ngwa ọla kọpa frosphorus

1. Ulo oru eletriki na eletriki

N'ihi ihe omume ya dị mma, na-emekwa ihe ọkụkụọla kọpa filperA na-ejikarị ya n'ọtụtụ na ngwaahịa dịka wires na eriri, igwe eletriki, njikọta, njikọ, wdg.

2. Igwe kemịkalụ

Na-eguzogide nkeọla kọpa phosphorusna-eme ka ha jiri ụlọ ọrụ kemịkalụ. Dịka ọmụmaatụ, ejiri ya mepụta akụrụngwa kemịkalụ kemịkalụ kemịkalụ kemịkalụ kemịkalụ kemịkalụ kemịkalụ, wdg, ọ nwere ike iguzogide ihe nchebe dị iche iche, na-ejide nchekwa na nkwụsi ike nke mmepụta.

3. Ndị na-emepụta ụlọ ọrụ

Na ụlọ ọrụ na-arụ ọrụ,ọla kọpa filperEnwere ike iji mepụta akụkụ dị iche iche dịka ihe dị iche iche dịka ihe dị iche iche dịka ihe dị mkpa, wdg.

4. Nrụpụta ụlọ ọrụ

Ọla kọpa filperA na-ejikwa ụlọ ọrụ na-ewu ihe, dị ka ụlọ na mma mma. Ọdịdị ya mara mma na nguzogide corrosion tinye ọmarịcha ụlọ ahụ.

3, atụmanya mmepe nke ọla kọpa phosphorus

Site na oganihu nke teknụzụ na mmepe aga n'ihu maka ụlọ ọrụ, ihe achọrọ maka Njirimara ihe na-abawanye.Ọla kọpa filper, dị ka ihe na-arụ ọrụ na-arụ ọrụ dị elu, nwere atụmanya mmepe.

N'ọdịnihu, na mmụba na-aga n'ihu nke nyocha na itinye ego na mmefu, arụmọrụ nke alperphorus nke ọla kọpa ga-akawanye mma. Iji maa atụ, site na ijikwa usoro ịhazi ihe na teknụzụ a na-arụ ọrụ, ike ya, ike ya, ike nguzogide na akụrụngwa ndị ọzọ enwere ike ime ka ọ dị ukwuu iji meziwanye ihe ndị ọzọ ojiji.

Ka ọ dịgodị, na mmụba na-aba ụba nke nchebe gburugburu ebe obibi, ọchịchọ maka ihe ndị na-eme enyi na enyi na-eto mgbe niile. Mpempe akwụkwọ ọla kọpa ọla, dị ka ihe ndị na-eme nchọpụta nke na-ezute ihe ndị metụtara gburugburu ebe obibi, ga-enwe uru na asọmpi ahịa ahịa n'ọdịnihu.

Na mpempe,ọla kọpa filperabụrụla ihe dị mkpa na mpaghara ụlọ ọrụ n'ihi ihe ndị pụrụ iche na ngwa ndị dị obosara. Site na oganihu na teknụzụ na mgbanwe dị n'ahịa,ọla kọpa phosphorusga-aga n'ihu na-etolite na ihe ohuru

Iji nye onyinye ka ukwuu iji kwalite ọganihu na mmepe nke ụlọ ọrụ.

For more information pls contact us :sales@shxlchem.com

Tel & Kedu ihe: 13524231522

Oge Post: Sepp-04-2024