Ngwa nkeỌdịda AlaNa nkedo aluminom alloy a na-ebugharị tupu mba ọzọ. Ọ bụ ezie na china malitere nyocha na itinye akwụkwọ nke akụkụ a naanị na 1960s, ọ na-eto ngwa ngwa. Emeela ọtụtụ ọrụ na usoro nchọpụta na ngwa dị mma, akụrụngwa nke ihe ndị dị oke mkpa na-arụ ọrụ dị oke mkpa n'ime ihe dị oke mkpa na-achagharị anya, ihe ọkụkụ na-acha uhie uhie, Ihe eji echekwa ahihia hydrogen, wdg.

Usoro usoro nke oke ụwa na aluminom na aluminom

A na-ejikarị ihe dị elu, ma nwee ike ịmekọrịta ihe fọrọ nke nta ka ọ bụrụ ihe dị ka ihe niile. A na-ejikọ ụwa niile na aluminom gụnyere La (lanthanum),oeridu), Y (yttrium) na SC (sayensi). A na-agbakwunyekarị ha n'ime mmiri nke alumini na ihe omimi, ndị ọrụ na-eme ihe na ndị ọrụ debere, nke nwere ike ime ka gbazee, na-eme ka ọ dị ọcha, wdg.

01Ịdị ọcha nke ụwa

Ka a ga-ewebata nnukwu ikuku (tumadi hydrogen, oxygen na ntụpọ nke aluminom) na-agbadata na mbelata nke ihe doro anya nke ọdịnaya hydrogen na a na-akwalite aluminom, mbelata nke piphole na ebe a na-ahụkarị, nke nwere ike ịmịpụta ihe na-emebi emebi na ihe omimi Ngwakọta nitrogen etolite etolite, nke a na-ewekarị n'ụdị slag na usoro ịse smoctive, ka iji mezuo ebumnuche nke mmiri mmiri aluminom.

Omume egosila na oke ụwa nwere mmetụta nke ibelata ọdịnaya nke hydrogen, oxygen na sulfur na aluminom na aluminom. Na-agbakwunye 0.1% nke 0.3% na-enye aka na-eme ka ọ dị mma ma ọ bụ na-emegharị ihe na-emebi emebi, ma nwee ike ịmịchasị wepụrụ, dị ka mmiri mmiri aluminom; ezigbo ihe ndị ọzọ na-aghọ nuclei nke aluminom ka ị nụchaa mkpụrụ ọka.

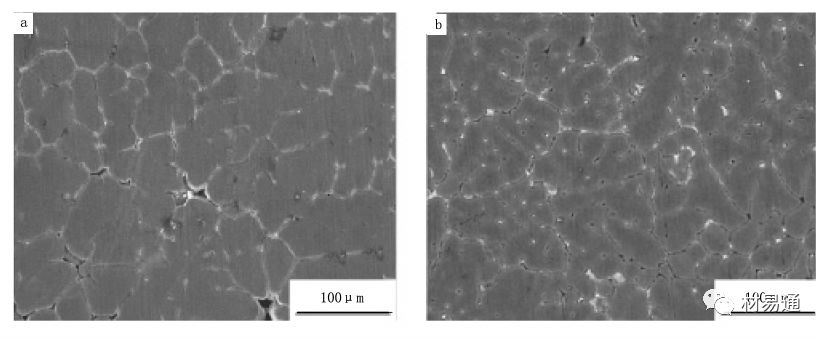

Fig 1 semphology nke 7075 alloy na-enweghị re na w (re) = 0.3%

a. Agbakwunyela; b. Tinye w (re) = 0.3%

02Metamorphism nke rare ụwa

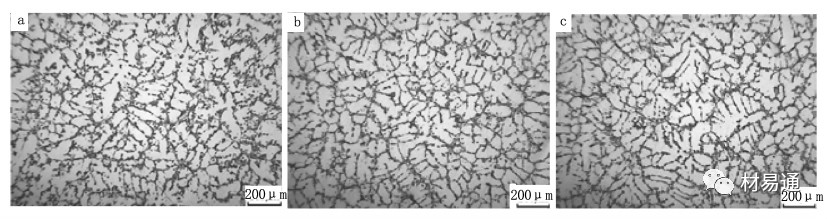

A na - egosipụta mgbanwe ụwa na - egosipụta na nsị ọka na dendrites, na - egbochi ọdịdị nke ahịhịa na nke atọ, na - agbasa elu ala karịa nke aluminom Atọm, na akụrụngwa ya na-arụsi ọrụ ike. Na-agbaze na mmiri mmiri a aluminium dị mfe mejupụta ntụpọ nke usoro a na-eme ka ọ dị n'etiti mkpụrụ osisi na-eme ka ọ bụrụ nke a na-emepụta ihe ma na-eme ka ihe nkiri a na-emepụta ihe ma na-eme ka ihe nkiri Alloy (lee eserese 2b).

Fig 2 micros na-enwe mgbakwunye

a. Recosage bụ 0; b. Refer bụ 0.3%; c. Refer bu 0.7%

Mgbe ị na-etinye akwụkwọ (ma ọ bụrụ na a na-eme ka ọ dị obere ma ọ bụ na-eme ka ọ dị obere). Metamorphism, na naanị mgbe a na-edebe ya na okpomọkụ ruo oge ụfọdụ, ọnụ ọgụgụ na-eme ka ụwa na-abawanye.

03 Ihe microlowing mmetụta nke oke ụwa

Oke ụwa dị na alluninum na aluminium n'ụdị atọ: ọgbụgba nri na-agbasi ike na-agbasi ike ma ọ bụ na-agbasi ike na usoro nke abụọ na-ewusi ike nke ụwa.

Thedị ịdị adị nke oke ụwa na aluminium na almuy alloy na mgbakwunye ya. N'ozuzu, mgbe ọ na-erughị 0.1%, ọrụ nke Redlocations na-eme ka ọ dị 0,25% dị mma, na-ekesakwa ọnụ ọgụgụ dị iche iche na-egosi, nke ga-emepụta micro Mmetụta alloying dị ka usoro nke abụọ na-ewusi ike.

Nsonaazụ nke oke ụwa na Njirimara nke aluminom na aluminom alloy alloy◆

01 Mmetụta nke oke ụwa na ihe ndị zuru oke nke alloy

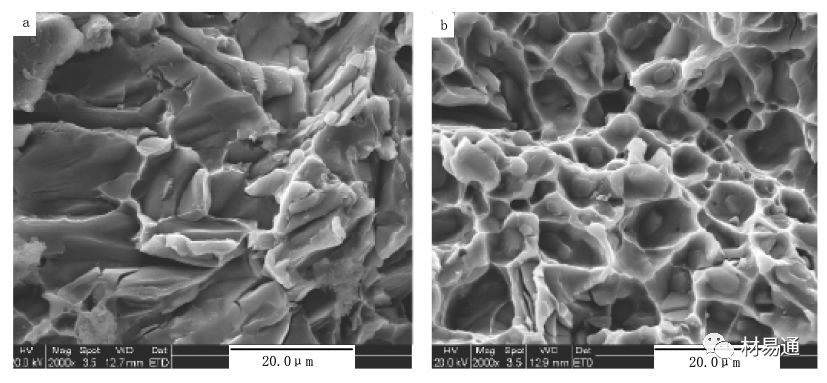

Ike, ihe siri ike, ihe mgbochibsite na 205.9 MPA na 274 MPA, na HB sitere na 80 ruo 108; itinye 0.42% sc na 7005 alloyσbmụbara site na 314MPA ruo 414MPA, σ0.2Mụbasị site na 2876PA ruo 378MPA, plastity plastity mụbara site na 6.8% ruo 10.8%, na nkwụsi ike dị elu. Dọnye 0.14% ~ 0.54%-6mg-0.5mn Alloy na-abawanye ike dị ukwuu site na 400%. 3 na-egosi na SEM na-eme ka nke al-si7-si7-mg0.8Alloy, nke na-egosi na ọ bụ ihe na-eme ka ọ ghara iche na-enweghị ọgba aghara na-enweghị re, mgbe ọ ga-agbakwunye 0.3% na-egosi na ọ na-egosi na ọ nwere ezigbo nsogbu na nkwanye ugwu.

Fig 3 tensile merụrụ morphology

a. Esonyeghi ya; b. Tinye 0,3% re

02Mmetụta nke oke ụwa na akụrụngwa dị elu nke alloys

Na-agbakwunye ụfọdụ egoỌdịda Alan'ime allininum alloy ike na-eme ka ọ dị mma na-eguzogide nke aluminom nile na-abawanye ma ọ bụ 44%, na-agbakwunye la, na-agbakwunye la, na Mischmetall ka ọ ga-eme CU almuoys nwere ike melite akụrụngwa dị elu nke alloys; A na-eme ka ọrụ okpomọkụ nke aluminom rụọ ọrụ nke ukwuu3S SR na-adị mfe coarsen na oke okpomọkụ ma na-eji matriks na-agbụ na-acha uhie uhie n'oge, na-eme ka ihe ndị dị elu na-enweghị atụ nke alloy.

03 Mmetụta nke oke ala na ngwa ngwa nke alloys

Na-agbakwunye ụwa a na-ahụkeba n'ime alluminom nwere ike ịgbanwe ihe ngosi elu ya, na-etinye elu profaịlụ nke na-acha odo odo na-acha odo odo na agba.

04 Mmetụta nke ụwa na-adịghị ahụkebe eletrik nke alloys

A na-eme ka aluminom dị elu dị elu na-emerụ ahụ na-eme ihe na-eme ihe na-eme ka a na-eme ihe ọ bụla na-eme ihe ọ bụla na-egosi Meziwanye ihe omume nke alloy, nke kacha nabata ọtụtụ n'ime ụlọ. Tinye tracwa ụwa ka ọ dị ọcha nke aluminom dị elu. Mgbe ejirila ya na ngwaahịa 25KV, okpukpu abụọ nke ikike ikike, ikike dị n'otu oge na-abawanye site na ugboro ise, a na-ebelata ibu ya na 47%, na oke olu na-ebelata.

05Mmetụta nke oke ala na corrosion iguzogide alloy

N'ụlọ ọrụ ụfọdụ, karịsịa na ọnụnọ chloride eons, allorion bụ enweghị ike corrosion, corrosion ike na corrosion ike ọgwụgwụ nke aluminom na-eguzogide ọnya, ọtụtụ ọmụmụ. Achọpụtara ya na ịgbakwunye ego kwesịrị ekwesị ụwa nke aluminom nwere ike ime ka ihe dị iche iche na-agbanwe agbanwe (0.1%) Nsonaazụ na-egosi na ịgbakwunye obere uwa dị ụkọ ruo na mmiri nke ahịhịa na-agba agba agba agba agba agba agba (wdg), wdg), wdg. Alloy, na-eme ka elu electrode nke aluminom na-eme ka ọ dị mma ma na-eme ka ndị na-eme ihe ike dị elu, na-agbakwunye na allinion nke alloy, na-agbakwunye na-emegide alloys, nke a na-eji dị ka ihe aerospace.

Nkwadebe Ntị nke Aluminum Alumoy Aluminum

A na-agbakwunye ụwa dị ụkọ na ụdị nke Chọpụta alloys na alloys ndị ọzọ. A na-eme ka ụwa dị oke elu, na-emegharị emegharị dị elu, dịkwa mfe ị oxidized ma kpọọ ya ọkụ na oke okpomọkụ. Nke a emeela ka ụfọdụ ihe isi ike na itinye nke ụwa nke aluminom.

01 Usoro agwakọta

Usoro nzere agwakọta bụ itinye ụwa ma ọ bụ gwakọta ahịhịa ụwa na-adị elu na-eme ka ọ dị elu ma ọ bụ itinye alloy Alloy na aluminom na-eme ka ọnụ dị na ya, na-ekpochapụ ma nụchaa.

02 Electrolysis

Limezọ nnu nnu electrolysis a na-eme bụ ịgbakwunye okirikiri ma ọ bụ na-arịa ọrịa almunolyze na electrolyze iji mepụta ụwa aluminom.monsten slat tolownight.Meven mebere ngwa ngwa na China. N'ozuzu, enwere ụzọ abụọ, ya bụ, usoro mmiri ọgwụ na usoro electrolytic eutectopytic. Ka ọ dị ugbu a, etolitela na enwere ike ịgbakwunye ogige nke aluminomytic, na creet ụwa nwere ike mepụta alloys nke chloride na-agbazekwa site na usoro eutectoid.

03 Usoro aluminothermic

N'ihi na alumini nwere ike mbelata, na aluminom nwere ike itolite udiri ihe di iche iche nke nwere ihe di iche iche, Aluminom di ka a na-agbaghari uwa aluminom.

RE2O3+ 6AL → 2Real2+ Al2O3

N'ime ha, enwere ike iji slag ụwa dị oke ọnụ ma ọ bụ na-ebelata ihe dị oke ọnụ ala, a na-ebugharị ya na ọnọdụ nke ịdị ọcha na-eme ka ọ bụrụ na ọ ga-akpata nsogbu. usoro mbelata. Na obere okpomọkụ (780 ℃), mmeghachi omume nke aluminothermic na-emecha na usoro sodium fluoride na sodium chloride, nke na-ezere nsogbu ndị ahụ dị elu nke okpomọkụ dị elu.

Itinye oganihu nke ala aluminom alloy aluminom ◆

01 Ngwa nke a almunom a allumoy alloy na ụlọ ọrụ ike

N'ihi oke echiche dị mma, dị elu na-ebugharị ugbu a, na-eyi ndọtị na-emepụta ihe dị mfe, nke na-eme ka ọ dị mma, nke dị na alloy na-emepụta ihe dị iche iche. Na nnukwu ọdịnaya, nke nwere mmetụta dị ukwuu na akụrụngwa eletriki. Na-agbakwunye ego kwesịrị ekwesị n'ụwa nwere ike ime ka ọ dị ugbu a na alloy Usoro almunium alloy. Ikike na ndị na-eduzi ụwa aluminom nwere ike iwelie ọnụ ụlọ elu USB ma gbasaa eriri ọrụ.

02Ngwa nke a almunom a allumoy na ụlọ ọrụ iwu

Aluminom alloy bụ ebe a na-ejikarị ụlọ ọrụ owuwu. A na-ahụta ihe dị ka 0.15% 0.155 ~ 0.25% nke nwere ike ime ka ihe owuwu na usoro a na-eme ihe, ma nwee ike imeziwanye ihe dị iche iche. Ofdị compands iji nụchaa usoro dendrate na mkpụrụ osisi, nke mere na nha nke diple ahụ na-abawanye, na njupụta na-abawanye, nke mere na a na-abawanye ngwa ngwa nke alloy. Dịka ọmụmaatụ, ike nke profaịlụ na-abawanye site na ihe karịrị 20%, mbara ihu na-abawanye site na 5%.

03Ngwa nke a aluminom a allumoy alloy na ngwaahịa kwa ụbọchị

Na-agbakwunye ihe mgbochi dị ka aluminom dị ọcha na alg usoro a almunium almumim, igbe nri, na-ejikwa akụkụ aluminom, na akụkụ nke aluminom Alloy nwere ihe karịrị okpukpu abụọ nke nguzogide na-eguzogide, 10% nke na-akwụ ụgwọ na-enweghị ihe ọ bụla, na ngwaahịa na-emepụta nke ukwuu, na-ere nke ọma na ahịa ụlọ na ndị ọzọ.

04 Ngwa nke a almunom a alluminum alloy na akụkụ ndị ọzọ

Na-agbakwunye puku kwuru puku ụwa na-eji Al Si usoro nkedo Alting nwere ike ime ka arụmọrụ utu aha nke alloy. Ejirila ọtụtụ ụdị ngwaahịa, ụgbọ mmiri, ụgbọ mmiri, akwara, na-eme ọgba tum tum na ngwa ahụ). Ejirila ike mgbasa ozi siri ike, a na-ewusi ike na-agbasi ike na akwara na-eme ka ọ bụrụ ike, ụgbọ mmiri, ụgbọ mmiri, wdg. Scandium almunium mepụtara site na NASA nwere ike ike na ọnọdụ okpomoku dị elu ma tinye ya na ụgbọ elu na obere ụgbọ elu;

Site na mp33, mbipụta 1 nke oke ala site na Wang Hui, Yang A na Yun Qi

Oge Post: Jul-05-2023