Porogaramu yaisi idasanzwemuri casting aluminium yakozwe mbere mumahanga.Nubwo Ubushinwa bwatangiye ubushakashatsi no gushyira mu bikorwa iyi ngingo gusa mu myaka ya za 1960, bwateye imbere byihuse.Ibikorwa byinshi byakozwe kuva mubushakashatsi bwibikorwa kugeza mubikorwa bifatika, kandi hari ibyagezweho. Hiyongereyeho ibintu bidasanzwe byubutaka, imiterere yubukanishi, ibikoresho byo gutara hamwe nu mashanyarazi ya aluminiyumu yatejwe imbere cyane.Mu rwego rwa ibikoresho bishya, ibintu byiza bya optique, amashanyarazi na magnetiki yibintu bidasanzwe byubutaka nabyo bigira uruhare runini mugukora isi idasanzwe ibikoresho bya magnetiki bihoraho, ibikoresho bidasanzwe bitanga urumuri rwisi, ibikoresho bidasanzwe byo kubika hydrogène, nibindi.

◆ mechanism Uburyo bwibikorwa byubutaka budasanzwe muri aluminium na aluminiyumu ◆ ◆

Ubutaka budasanzwe bufite ibikorwa bya chimique byinshi, ubushobozi buke hamwe na elegitoronike idasanzwe itunganijwe, kandi irashobora gukorana nibintu hafi ya byose. Ubutaka budasanzwe bukoreshwa muri aluminiyumu na aluminiyumu harimo La (lanthanum), Ce (cerium), Y (yttrium) na Sc (scandium).Bakunze kongerwaho mumazi ya aluminiyumu hamwe na modifiseri, nucleating agent na degassing agent, zishobora kweza gushonga, kunoza imiterere, gutunganya ingano, nibindi.

01Kweza isi idasanzwe

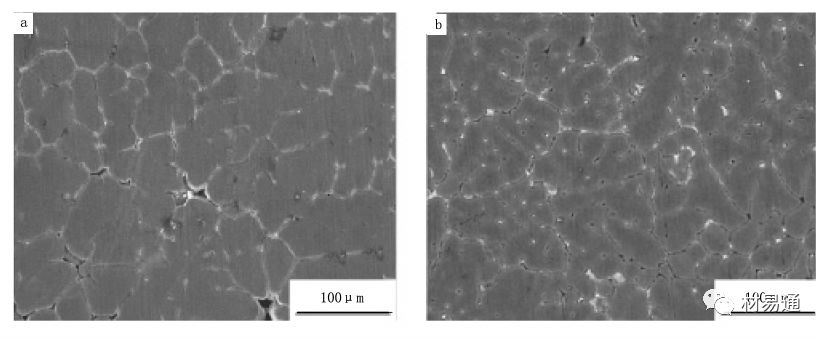

Nka gaze nini ya gaze hamwe na okiside (cyane cyane hydrogène, ogisijeni na azote) bizazanwa mugihe cyo gushonga no guterera amavuta ya aluminiyumu, pinholes, ibice, ibice hamwe nizindi nenge bizagaragara mugukina (reba Ishusho 1a), bigabanye imbaraga za aluminiyumu. Ingaruka zo kweza isi idasanzwe zigaragarira cyane cyane mukugabanuka kugaragara kwa hydrogène muri aluminiyumu yashongeshejwe, kugabanya igipimo cya pinhole no kwishongora (reba Ishusho 1b), no kugabanya ibiyirimo nibintu byangiza. Ibyingenzi Impamvu nuko isi idasanzwe ifitanye isano na hydrogène, ishobora gukurura no gushonga hydrogène ku bwinshi kandi ikabyara ibintu bitajegajega idashizeho ibibyimba byinshi, bityo bikagabanya cyane ibirimo hydrogène hamwe nubushake bwa aluminium; Ubutaka budasanzwe na azote bigira ibice bivangavanze, aribyo ahanini yakuweho muburyo bwa slag muburyo bwo gushonga, kugirango ugere ku ntego yo kweza amazi ya aluminium.

Imyitozo yerekanye ko isi idasanzwe ifite ingaruka zo kugabanya ibirimo hydrogene, ogisijeni na sulfure muri aluminium na aluminiyumu.Ongeraho 0.1% ~ 0.3% RE mumazi ya aluminiyumu bifasha gukuraho neza umwanda wangiza, gutunganya umwanda cyangwa guhindura morfologiya, kugirango utunganyirize kandi ugabanye ingano; RES, REAs, na REPb, zirangwa no gushonga cyane, ubucucike buke, hamwe nimiti ihamye yimiti, kandi birashobora kureremba hejuru kugirango bibe shitingi hanyuma bikurweho, bityo bisukure amazi ya aluminiyumu; ibice byiza bisigaye bihinduka nuclei ya heterogeneous ya aluminium kugirango itungwe neza ibinyampeke.

Igishushanyo 1 SEM Morphologiya ya 7075 Alloy idafite RE na w (RE) = 0.3%

a.RE ntabwo yongeyeho; b.Ongeraho w (RE) = 0.3%

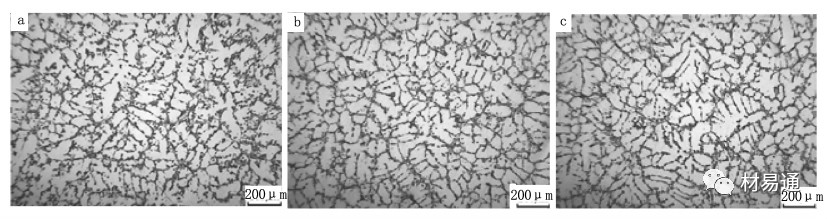

02Metamorphism yisi idasanzwe

Guhindura isi gake cyane bigaragarira cyane cyane mu gutunganya ibinyampeke na dendrite, bikabuza kugaragara kwicyiciro cya lamellar T2, gukuraho icyiciro kinini cyagabanijwe muri kristu yambere kandi kigakora icyiciro cya serefegitura, kuburyo ibice hamwe nibice bivangwa kumupaka wingano bigabanuka cyane. .Gushonga mumazi ya aluminiyumu biroroshye cyane kuzuza ubusembwa bwubuso bwicyiciro cya alloy, bigabanya impagarara zubuso hejuru yimbere hagati yicyiciro gishya nicyashaje, kandi bikazamura umuvuduko wubwiyongere bwa nucleus ya kirisiti; Mugihe kimwe, irashobora kandi gukora ubuso firime ikora hagati yintete namazi yashongeshejwe kugirango ikumire gukura kwimbuto zabyaye no kunonosora imiterere (reba Ishusho 2b).

Igishushanyo 2 Microstructure ya Alloys hamwe na RE itandukanye

a.Igipimo cya RE ni 0; b.RE wongeyeho ni 0.3%; c.RE wongeyeho ni 0.7%

Nyuma yo kongeramo ibintu bidasanzwe byisiαIbinyampeke byicyiciro cya (Al) byatangiye kuba bito, byagize uruhare mugutunganya ibinyampekeα (Al) byahinduwe muburyo buto bwa roza cyangwa inkoni, mugihe ibiri mubutaka budasanzwe ari 0.3% αUbunini bwa (Al ) icyiciro ni gito, kandi kigenda cyiyongera buhoro buhoro hamwe no kwiyongera kwinshi kubutaka budasanzwe.Ubushakashatsi bwerekanye ko hari igihe runaka cyo kubaga kubutaka budasanzwe metamorphism, kandi iyo bibitswe ku bushyuhe bwo hejuru mugihe runaka, isi idasanzwe izagira uruhare runini muri metamorphism. Byongeye kandi, umubare wa nuclei ya kirisiti ya kirisiti yibintu byakozwe na aluminium nubutaka budasanzwe byiyongera cyane mugihe ibyuma bya kristalisiti, ari nako bituma imiterere ya alloy itunganijwe.Ubushakashatsi bwerekana ko isi idasanzwe ifite ibyiza Ingaruka zo guhindura kuri aluminiyumu.

03 Ingaruka ya Microalloying yisi idasanzwe

Ubutaka budasanzwe bubaho cyane muri aluminiyumu na aluminiyumu muburyo butatu: igisubizo gikomeye muri matrixα (Al); Gutandukanya imbibi zicyiciro, imbibi zimbibi nimbibi za dendrite; Igisubizo gikomeye cyangwa muburyo bwo guhuza.Ingaruka zikomeye zubutaka budasanzwe muri aluminiyumu ikubiyemo cyane cyane kunonosora ingano, gushimangira igisubizo cyanyuma hamwe nicyiciro cya kabiri gushimangira ibinyabuzima bidasanzwe.

Imiterere yo kubaho kwisi idasanzwe muri aluminium na aluminiyumu ifitanye isano rya hafi nubwinshi bwayo.Mubisanzwe, iyo RE iri munsi ya 0.1%, uruhare rwa RE ni ugushimangira ingano nziza no gushimangira igisubizo cyanyuma; Iyo RE irimo 0.25% ~ 0,30%, RE na Al bagize umubare munini winkoni nini cyangwa ngufi nkibintu bivanze; , zikwirakwizwa mu mbibi cyangwa ingano, hamwe n’umubare munini wa dislokasiyo, inzego nziza za spheroidized ingano hamwe n’imisemburo y’ubutaka idasanzwe ikwirakwizwa, bizatanga ingaruka ziterwa na mikorobe nko gushimangira icyiciro cya kabiri.

◆ earth Ingaruka zubutaka budasanzwe kumiterere ya aluminium na aluminiyumu ◆◆

01 Ingaruka yubutaka budasanzwe kumiterere yubukorikori bwuzuye

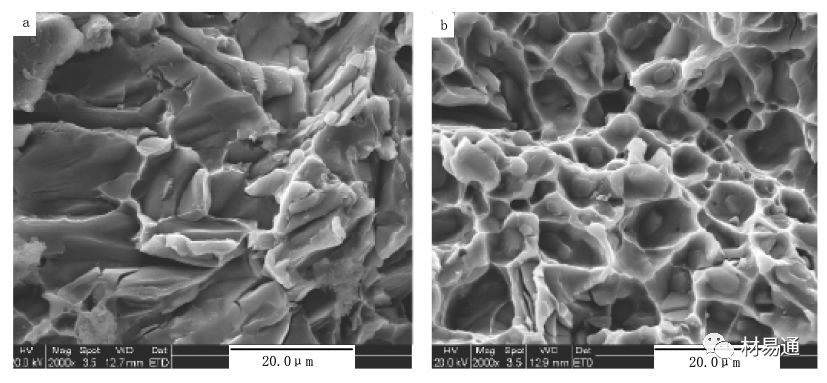

Imbaraga, ubukana, kuramba, gukomera kuvunika, kwambara birwanya hamwe nubundi buryo bwuzuye bwubukanishi bwa alloy birashobora kunozwa hiyongereyeho isi ikwiye.0.3% RE yongewe kumurongo wa aluminium ZL10 alloyσbkuva 205.9 MPa kugeza 274 MPa, na HB kuva 80 kugeza 108; Ongeraho 0.42% Sc kuri 7005 alloyσbyiyongereye kuva 314MPa igera kuri 414MPa, σ0.2yiyongereye kuva kuri 282MPa igera kuri 378MPa, plastike yiyongereye kuva kuri 6.8% igera kuri 10.1%, kandi ubushyuhe bwo hejuru bwo hejuru bwarushijeho kwiyongera; La na Ce zirashobora kuzamura cyane ubudahangarwa bwimvange.Ongeraho 0.14% ~ 0,64% La kuri Al-6Mg-0.5Mn ibinyobwa byongera superplasticity kuva kuri 430% bikagera kuri 800% ~ 1000%; Ubushakashatsi butunganijwe kuri Al Si alloy bwerekana ko imbaraga zumusaruro nimbaraga za tensile zanyuma zivanze zishobora kuba nyinshi kunonosorwa wongeyeho umubare ukwiye wa Sc.Fig.3 yerekana isura ya SEM yo kuvunika kwinshi kwa Al-Si7-Mg0.8alloy, yerekana ko ari ibisanzwe bivunika byavunitse bidafite RE, mugihe nyuma ya 0.3% RE byongeweho, imiterere ya dimple igaragara igaragara muvunika, byerekana ko ifite ubukana bwiza no guhindagurika.

Igishushanyo cya 3 Kumeneka Kumeneka Morphology

a.Ntabwo yinjiye muri RE; b.Ongeraho 0.3% RE

02Ingaruka Zidasanzwe Isi Kubushyuhe Bwinshi Bwiza bwa Alloys

Ongeraho umubare runaka waisi idasanzwemuri aluminiyumu irashobora kunoza neza ubushyuhe bwo hejuru bwa okiside irwanya aluminiyumu.Kongeramo 1% ~ 1.5% ivanze nubutaka budasanzwe kubutaka bwa Al Si eutectic alloy byongera ingufu zubushyuhe bwo hejuru kuri 33%, imbaraga zo guturika hejuru (300 ℃, Amasaha 1000) kuri 44%, kandi kwihanganira kwambara hamwe nubushyuhe bwo hejuru biratera imbere cyane; Ongeraho La, Ce, Y hamwe nuburyo budahwitse bwo gutera Al Cu alloys birashobora kuzamura imiterere yubushyuhe bwo hejuru bwimvange; Al-8.4% byihuta cyane; Fe-3,4% Ce alloy irashobora gukora igihe kirekire munsi ya 400 ℃, igatera imbere cyane ubushyuhe bwakazi bwa aluminiyumu; Sc yongewe kuri Al Mg Si alloy kugirango ikore Al3Sc uduce duto tutoroshye guhurirana mubushyuhe bwinshi kandi bigahuza na matrix kugirango duhuze imbibi zingano, kugirango ibivange bigumane imiterere idahwitse mugihe cya annealing, kandi bitezimbere cyane ubushyuhe bwo hejuru bwubushyuhe.

03 Ingaruka Yisi Ntibisanzwe Kubintu Byiza bya Alloys

Ongeraho isi idasanzwe muri aluminiyumu irashobora guhindura imiterere ya firime ya oxyde ya oxyde, bigatuma ubuso burushaho kuba bwiza kandi bwiza.Iyo 0.12% ~ 0.25% RE yongewe kumyunyu ngugu ya aluminiyumu, kwerekana imiterere ya okiside kandi ifite amabara 6063 bigera kuri 92%; Iyo 0.1% ~ 0.3% RE yongewe kuri Al Mg cast ya aluminiyumu, ibinyomoro birashobora kubona ubuso bwiza bwo kurangiza no kuramba.

04 Ingaruka z'isi idasanzwe ku mashanyarazi ya Alloys

Ongeraho RE kuri aluminiyumu-isukuye cyane ni bibi kwangiza amavuta, ariko ubwikorezi burashobora kunozwa kurwego runaka wongeyeho RE ikwiye kuri aluminiyumu yinganda zikora inganda hamwe na Al Mg Si itwara amavuta. Ibisubizo byubushakashatsi byerekana ko ubwikorezi bwa aluminium Irashobora kunozwa na 2% ~ 3% wongeyeho 0.2% RE.Kongeramo agace gato ka yttrium ikungahaye cyane mubutaka budasanzwe muri Al Zr alloy irashobora kunoza imikoreshereze yimyunyungugu, yemejwe ninganda nyinshi zo murugo; Ongeraho isi idasanzwe kuri aluminiyumu-yera cyane kugirango ikore Al RE foil capacitor.Iyo ikoreshejwe mubicuruzwa 25kV, indangagaciro ya capacitance yikubye kabiri, ubushobozi kuri buri gice cyiyongereyeho inshuro 5, uburemere bugabanukaho 47%, nubunini bwa capacitori buragabanuka cyane.

05Ingaruka Zisi Ntibisanzwe Kurwanya Ruswa Kurwanya Alloy

Mu bidukikije bimwe na bimwe bya serivisi, cyane cyane imbere ya ion ya chloride, ibinyomoro byibasirwa na ruswa, kwangirika kwa crevice, guhangayika no kunanirwa kwangirika.Mu rwego rwo kunoza kwangirika kwangirika kwa aluminiyumu, ubushakashatsi bwinshi bwakozwe.Byagaragaye ko kongeramo ubutaka bukwiye kubutaka bwa aluminiyumu bishobora kunoza neza kurwanya kwangirika kwabo. Ingero zakozwe mugushyiramo ibice bitandukanye bivanze nubutaka budasanzwe (0.1% ~ 0.5%) kuri aluminiyumu byashizwe mumazi ya brine hamwe ninyanja yubukorikori inshuro eshatu zikurikiranye. imyaka.Ibisubizo byerekana ko kongeramo umubare muto wubutaka budasanzwe kuri aluminiyumu bishobora guteza imbere kurwanya ruswa ya aluminiyumu, kandi kurwanya ruswa mu mazi y’inyanja n’inyanja biri hejuru ya 24% na 32% ugereranije na aluminiyumu; isi idasanzwe igizwe nibintu byinshi byinjira (La, Ce, nibindi), urwego rwa firime idasanzwe yo guhindura isi irashobora gushingwa hejuru yubutaka bwa 2024, bigatuma ubushobozi bwa electrode yubutaka bwa aluminiyumu ikunda kuba imwe, kandi bikazamura imbaraga zo kurwanya kwangirika hagati yimitsi no guhangayika; Kwongeramo La kuri aluminiyumu ya Mg ya aluminiyumu birashobora kuzamura cyane ubushobozi bwo kurwanya ruswa yo mu mazi ya aliyumu; Kwongeramo 1.5% ~ 2.5% Nd kuri aluminiyumu irashobora kunoza imikorere yubushyuhe bwo hejuru, ubukana bwikirere hamwe no kurwanya ruswa ya ibinyobwa, bikoreshwa cyane nkibikoresho byo mu kirere.

Technology technology Gutegura tekinoroji yubutaka budasanzwe aluminium alloy ◆ ◆

Isi idasanzwe yongewemo muburyo bwibintu bya trike muri aluminiyumu nandi mavuta.Isi idakunze kugira ibikorwa byinshi bya shimi, gushonga cyane, kandi biroroshye guhinduka okiside no gutwikwa mubushyuhe bwinshi.Ibi byateje ingorane zimwe na zimwe mugutegura no gukoresha isi idasanzwe ya aluminium aluminiyumu.Mu bushakashatsi bwigihe kirekire bwubushakashatsi, abantu bakomeje gushakisha uburyo bwo gutegura ibinyabuzima bidasanzwe bya aluminiyumu. zirimo kuvanga uburyo, uburyo bwo gushonga umunyu electrolysis hamwe nuburyo bwo kugabanya aluminothermic.

01 Uburyo bwo kuvanga

Uburyo buvanze bwo gushonga ni ukongeramo isi idasanzwe cyangwa kuvanga ibyuma bidasanzwe byisi mumazi yubushyuhe bwo hejuru bwa aluminiyumu ugereranije no gukora ibishushanyo mbonera cyangwa gukoresha amavuta, hanyuma ugashonga ibishushanyo mbonera hamwe na aluminiyumu isigaye ukurikije amafaranga yabazwe hamwe, ukabyutsa neza kandi ukanonosora. .

02 Electrolysis

Uburyo bwa elegitoronike yumunyu wa elegitoronike ni ukongeramo okiside yisi idasanzwe cyangwa umunyu wubutaka budasanzwe mumasoko ya aluminium electrolytike yinganda na electrolyze hamwe na oxyde ya aluminiyumu kugirango itange isi idasanzwe ya aluminiyumu.Mubisanzwe, hari inzira ebyiri, arizo, uburyo bwa cathode bwamazi nuburyo bwa electrolytike eutectoid.Kugeza ubu, byatejwe imbere ko ibinyabuzima bidasanzwe by’ubutaka bishobora kwongerwaho mu ngirabuzimafatizo za aluminium electrolytike y’inganda, kandi isi idasanzwe ya aluminiyumu irashobora gukorwa na electrolysis ya chloride yashonga hakoreshejwe uburyo bwa eutectoid.

03 Uburyo bwo kugabanya Aluminothermic

Kuberako aluminiyumu ifite ubushobozi bukomeye bwo kugabanya, kandi aluminiyumu irashobora gukora ibintu bitandukanye bivangavanze hamwe nubutaka budasanzwe, aluminiyumu irashobora gukoreshwa nkigabanuka ryogutegura isi idasanzwe ya aluminiyumu. Ibisubizo nyamukuru byimiti byerekanwe muburyo bukurikira:

RE2O3+ 6Al → 2REAl2+ Al2O3

Muri byo, isi idasanzwe ya okiside cyangwa isi idasanzwe ikungahaye irashobora gukoreshwa nkibikoresho bidasanzwe byisi; Igabanuka rishobora kuba inganda nziza ya aluminiyumu cyangwa aluminium ya silicon; Ubushyuhe bwo kugabanuka ni 1400 ℃ ~ 1600 ℃ .Mu ntangiriro, yari yatwaye hanze yuburyo bwo gushyushya ibintu no gutemba, kandi ubushyuhe bwo kugabanuka bwatera ibibazo byinshi; Mu myaka yashize, abashakashatsi bakoze uburyo bushya bwo kugabanya aluminothermic.Ku bushyuhe buke (780 ℃), reaction ya aluminothermic yo kugabanuka irangizwa muri sisitemu ya sodium fluoride na sodium chloride, birinda ibibazo biterwa nubushyuhe bwo hejuru.

◆ Gukoresha iterambere ryisi idasanzwe ya aluminium alloy ◆ ◆

01 Gukoresha isi idasanzwe ya aluminium alloy mu nganda zingufu

Bitewe nibyiza byo gutwara neza, ubushobozi bunini bwo gutwara, imbaraga nyinshi, kwihanganira kwambara, gutunganya byoroshye no kubaho igihe kirekire, isi idasanzwe ya aluminiyumu irashobora gukoreshwa mugukora insinga, imirongo yohereza hejuru, insinga, insinga zinyerera hamwe ninsinga zoroshye kuri intego zidasanzwe. Ongeraho umubare muto wa RE muri sisitemu ya Al Si alloy irashobora kunoza imikorere, ni ukubera ko silicon iri muri aluminiyumu ari ikintu cyanduye gifite ibintu byinshi, gifite ingaruka zikomeye kumashanyarazi.Ongeraho umubare ukwiye wubutaka budasanzwe birashobora kunoza morphologie ihari no gukwirakwiza silikoni muri alloy, ishobora guteza imbere neza amashanyarazi ya aluminium; Ongeramo agace gato ka yttrium cyangwa yttrium ikungahaye ku isi idasanzwe mu nsinga irwanya ubushyuhe bwa aluminium alloy ntishobora gukomeza gukora neza ubushyuhe bwo hejuru gusa ahubwo inatezimbere ubworoherane; Isi idasanzwe irashobora kuzamura imbaraga zingana, kurwanya ubushyuhe no kurwanya ruswa ya sisitemu ya aluminium.Intsinga hamwe nuyobora bikozwe mubutaka budasanzwe aluminiyumu irashobora kongera uburebure bwumunara wa kabili kandi ikongerera igihe cyumurimo winsinga.

02Gukoresha isi idasanzwe ya aluminiyumu mu nganda zubaka

6063 aluminiyumu ikoreshwa cyane mu nganda zubaka.Ongeraho 0.15% ~ 0,25% isi idasanzwe irashobora guteza imbere cyane nkimiterere yimiterere nuburyo bwo gutunganya, kandi irashobora kunoza imikorere yo gukuramo, ingaruka zo kuvura ubushyuhe, imiterere yubukanishi, kurwanya ruswa, imikorere yubutaka hamwe nijwi ryamabara.Bisanga isi idasanzwe ari cyane ikwirakwizwa muri 6063 aluminium alloyα-Al itesha agaciro imbibi zicyiciro, imbibi zintete na interdendritic, kandi bigashonga mubice cyangwa bikabaho muburyo bwimvange kugirango binonosore imiterere ya dendrite nintete, kuburyo ubunini bwa eutectic idashonga nubunini ya dimple mu gace ka dimple iba ntoya cyane, ikwirakwizwa ni rimwe, kandi ubucucike bwiyongera, kuburyo imitungo itandukanye ya alloy itezimbere kuburyo butandukanye.Kurugero, imbaraga zumwirondoro ziyongereyeho hejuru ya 20%, kuramba byiyongereyeho 50%, naho igipimo cyo kwangirika kigabanuka inshuro zirenze ebyiri, Ubunini bwa firime ya oxyde bwiyongera 5% ~ 8%, na imitungo yamabara yiyongera hafi 3% .Nuko rero, imyirondoro yinyubako ya RE-6063 ikoreshwa cyane.

03Gukoresha isi idasanzwe aluminiyumu mubicuruzwa bya buri munsi

Ongeraho isi idasanzwe kuri aluminiyumu yera na Al Mg ikurikirana ya aluminiyumu yo gukoresha buri munsi ibicuruzwa bya aluminiyumu birashobora guteza imbere cyane imiterere yubukanishi, imitungo ishushanya cyane hamwe no kurwanya ruswa. Ibikenerwa buri munsi nkibikono bya aluminiyumu, amasafuriya ya aluminium, amasahani ya aluminium, ibikoresho bya aluminiyumu bifasha, amagare ya aluminium, hamwe nibikoresho byo murugo bikozwe muri Al Mg RE alloy bifite inshuro zirenga ebyiri kurwanya ruswa, kugabanya ibiro 10% ~ 15%, kongera umusaruro 10% ~ 20%, kugabanya ibiciro byumusaruro 10% ~ 15%, no gushushanya byimbitse no gutunganya byimbitse ugereranije nibicuruzwa bya aluminiyumu idafite isi idasanzwe. Kugeza ubu, ibikenerwa bya buri munsi byubutaka budasanzwe bwa aluminium aluminiyumu byakoreshejwe henshi, kandi ibicuruzwa byiyongereye cyane, kandi bigurishwa neza kumasoko yimbere mu gihugu no mumahanga. .

04 Gukoresha isi idasanzwe ya aluminium alloy mubindi bice

Ongeraho ibihumbi bike byubutaka budasanzwe mukoresha cyane Al Si serie ya casting alloy irashobora kunoza cyane imikorere yimashini.Ibirango byinshi byibicuruzwa byakoreshejwe mu ndege, mu mato, mu binyabiziga, moteri ya mazutu, moto n’ibinyabiziga byitwaje ibirwanisho (piston, garebox, silinderi, ibikoresho nibindi bice) .Mu bushakashatsi no kubishyira mu bikorwa, usanga Sc ari ikintu cyiza cyane kuri hindura imiterere nimiterere ya aluminiyumu.Ifite imbaraga zikomeye zo gukwirakwiza, gushimangira ingano, kunoza igisubizo hamwe na microalloy ikomeza ingaruka kuri aluminium, kandi irashobora guteza imbere imbaraga, ubukana, plastike, ubukana, kurwanya ruswa, kurwanya ubushyuhe, nibindi bya alloys.Sc Al series alloys yakoreshejwe inganda zikorana buhanga cyane nko mu kirere, amato, gariyamoshi yihuta, ibinyabiziga byoroheje, n'ibindi. 557 ibice byubatswe; 0146Al Cu Li Sc alloy yakozwe nu Burusiya yakoreshejwe kuri tank ya lisansi ya kirogenike yicyogajuru.

Kuva mu Mubumbe wa 33, nomero 1 yisi idasanzwe na Wang Hui, Yang An na Yun Qi

Igihe cyo kohereza: Jul-05-2023