Ticton Carbide Ti3SIC2 Powder

TLHOKOMELISO

Ti3Alc2

Aluminium titanium Carbide ke thepa e ncha ea feramase e nang le sebopeho se ikhethang sa ternary, e nang le thepa e ikhethang, e 'nile ea ela hloko bo-ramahlale ba lintho tse bonahalang le litsebi tsa bana ba li-nkhono. Aluminium titanium carbide (Ti3iaic2) e ba lesions ea Hexage E na le boitšoaro bo botle, boitšoaro bo bobe le bo-Moduluse bo phahameng ba Modulus ba matla le ho ba thata Ho khona ho seha ka mocheso oa kamore le boto ea polasetiki ka mocheso o phahameng; E boetse e na le botsitso ba phahameng ba mocheso le ho hanyetsana le oxidation. Ka nako e ts'oanang, e boetse e na le khatello e ntle ea vibramele, ho hanyetsa ho senya batho le khanyetso e ntle ea lik'hemik'hale tse ngata tsa lik'hemik'hale.

| Lebitso la Product | Ti3Alc2 |

| Ponahalo | Grey o lefifi |

| Boholo ba karolo | 100Mesh 200mesh 300Mesh 0-60 |

| Boitšoaro ba motlakase | 3.1 * 10SM |

| Boima ba Molecular | 194.6 |

| bohloeki | 99% min |

| Kopo | Ka matla le matla a phahameng le alatulus, ho ba le boitšoaro bo phahameng ba motlakase le boitšoaro bo botle ba motlakase, mechine e metle |

| Lintlha tsa Ti3Alc2 | |||||||

| Bohloeki | Ti | Al | C | P | S | Fe | Si |

| 99 | 73.8 | 13.16 | 12.0 | 0.002 | 0.0015 | 0.12 | 0.02 |

Ti3sic2

Ti3SIC2 phofo e sebelisoa e le lisebelisoa tse ikhethileng tsa lehole, thepa ea elektroniki, lisebelisoa tsa mocheso tse phahameng, lisebelisoa tsa khang ea li-anti-drish tsa motlakase.

Mana a matata a titanium a na le menyetla e mengata ea tšepe le li-ferikics. Joalo ka tšepe, ke mokhanni ea motle oa motlakase le mocheso. Ho bonolo ho sebetsana le maemo, bonolo, e se nang tšabo ho makala a chesang a futhumatsang, 'me e bontša polasetiki ka lithemparetjha tse phahameng. E boetse e hanana le oxidation le mocheso o phahameng joalo ka sistimi. Matla a mocheso o phahameng a feta aloys tsohle tse phahameng.

E le thepa ea mocheso e phahameng, Ti3SIC2 e na le boitšoaro ba motlakase habeli bo sa tsamaiseng. E ea unyenyetsi 'me e na le melemo e hlakileng joaloka borashe bakeng sa borashe ba ac. Matla a eona a mocheso oa sona e phahameng, ho hanyetsa ha khatello ea kelello, 'me ho hana ho tšosa molumo ho ka fihlela sebe. Ho ka etsahala hore tšepe e nkhang hamonate e ka sebelisoa ka lebaka la ho hanela ho tsitsipana ha tsona e ntle ea mafura le boitšoaro bo phahameng ba motlakase. Ka kakaretso, ho na le thepa ea matanium ea titanium e nang le boleng bo holimo ka boleng ba boleng ba lipatlisiso le tebello ea ts'ebetso.

| Lebitso la Product | Ti3sic2 |

| Mmala | Grey o lefifi |

| bohloeki | 99% min |

| Foromo ea Crystal | cubic |

| sebopeho sa lik'hemik'hale | TI: 73-74 si: 14-15 c: 12-13 nyonya: <0,5 |

| Ntlha ea ho qhibiliha | 3106 ℃ |

| Letsoalo | 5.87 g / cm3 |

| Sebaka se ikhethileng | 14.92M2 / G |

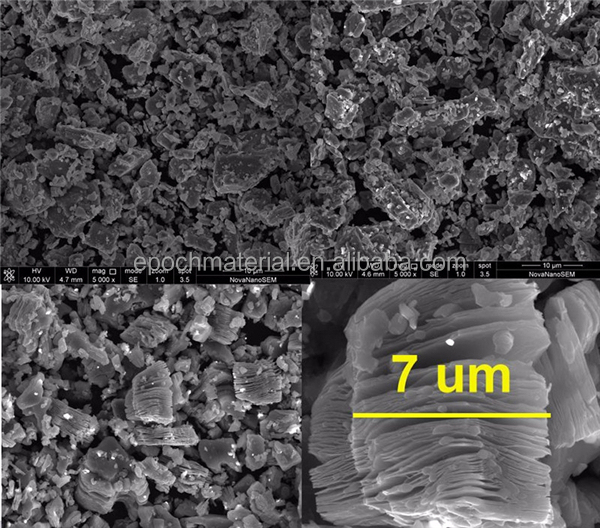

| Boholo | 100Mesh 300Mesh 200melo |

| Kopo | Biomedical referactory |

Lintlha tsa Ti3SIC2

| Bohloeki | Ti | Si | C | LITLHAKISO TSA BOPHELO |

| 99 | 73.1 | 14.5 | 12.11 | ≤0.3% |

Setifikeiti:

Seo re ka se Fanang ka Sona: