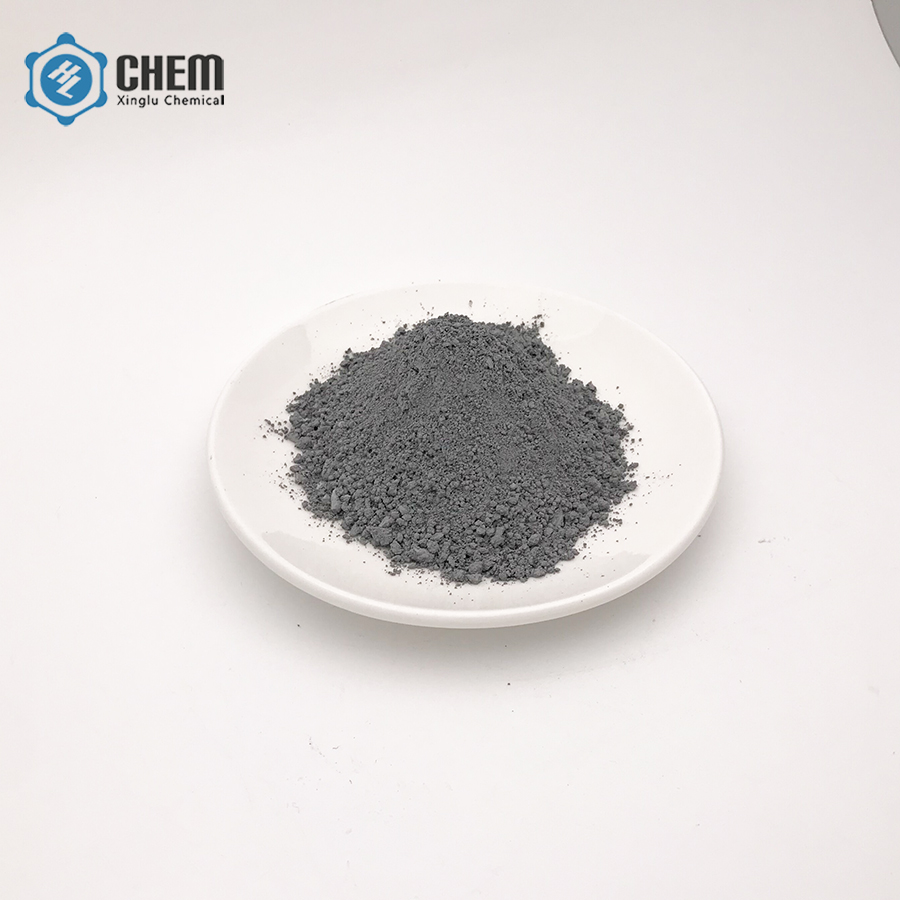

Tin Copper (SN-Cu) alloy phofo

Kono Tin Copper Alloy Alloy (NanoSn-cu alloy phofo) 80nm

Litekanyetso tsa tekheniki

| Mohlala | APS (NM) | Bohloeki (%) | Sebaka se ikhethileng sa bokalimo (m2/ g) | Molumo oa molumo oa molumo (g / cm3) | Foromo ea Crystal | Mmala | |

| Nano | Xl-sn-cu | 80 | > 99.8 | 7.39 | 0.19 | spinical | E ntšo |

| Hlokomela | E ka fana ka lijo tse fapaneng bakeng sa lihlahisoa tse anyang ho latela litlhoko tsa moreki | ||||||

Ts'ebetso ea Lihlahisoa

Mokokotlo oa laser oa laser oa "

Tataiso ea kopo

Lipole tsa lithium, li ntlafatsa bophelo ba betri le likolo tsa lits'ebeletso tse kanang ka sekoti, likoloi tsa motlakase, EncTunt Devices jj ..

Joalokaha lisebelisoa tsa ho kenyelletsa Melfadgy, litloholo tsa lijo tsa lijo-thollo, ho ba ha ho hasatla ho matlafatsa thepa ea lintho tse bonahalang.

Maemo a polokelo

Sehlahisoa sena se lokela ho bolokoa ka ho omella, se pholileng le ho tiisa tikoloho, ho ke ke ha thusa moea o boima, ho latela lipalangoang tsa thepa e tloaelehileng.

Setifikeiti:

Seo re ka se Fanang ka Sona: