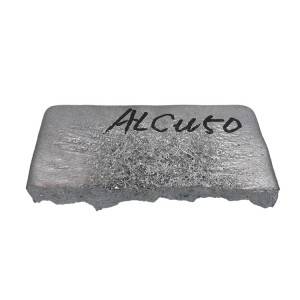

I-Copper Calcium Calcium Cumali Master alloy Cuca20 Cuca30 Cuca30 yensimbi

I-calcium calcium ye-calcium master alloy CUCA30 Cuca20I-Ingots yensimbi

I-Copper-Calcium master alloyisetyenziselwa ukuveliswa kwezinto ezahlukeneyo zobhedu. Olu mafutha ka-Master Alloy lwenziwe ngokudibanisa ubhedu kunye ne-calcium kwimilinganiselo ethile (ihlalaCuca20okanye i-cuca30) yokufezekisa iipropathi ezinqwenelekayo kunye neempawu ezifunekayo kwisicelo esithile.

I-calcim-calcium master alloyszisetyenziswa ngokubanzi ekwenzeni ubhedu kunye ne-alloys yayo ngenxa yokukwazi kwabo ukuphucula iipropathi zoomatshini kunye neepropathi zemveliso yokugqibela. Yaziwa ngokuba ziipropathi zayo ezilungileyo kakhulu kwaye zinceda ekuphuculeni umgangatho wezinto ezisekwe kuzo. Ukongeza, ukongeza i-calcium ukuya kwi-Copper kuphume ukuphucula ukwenzeka kwe-thermal kunye nendlela yombane, iyenza ilungele ukusetyenziswa kumashishini ombane kunye nemoto.

Enye yezona zinto zibalulekileyo zokusebenzisa iI-Copper-Calcium master alloykukwazi ukunciphisa iindleko zemveliso ngokubanzi. Ngokongeza i-AFTAL ALTION kwi-Copper yobhedu, ukusetyenziswa kwe-calcium ecocekileyo kwaye ubhedu lunokuncitshiswa, malunga nokonga iindleko kwinkqubo yokwenziwa. Ukongeza, ukusetyenziswa kwe-Aff Altrays iqinisekisa ukusasazwa okulawulwa okungakumbi kunye nokufakwa kwezinto zemveliso kwimveliso yokugqibela, ngaloo ndlela kuphuculwe ukungqinelana kunye nomgangatho.

Ukusetyenziswa kweI-calcim-calcium master alloysBenza balungele uluhlu olubanzi lwezicelo, kubandakanya ukuveliswa kweengcingo zombane, izinto zemoto kunye neenxalenye ezahlukeneyo zoomatshini. Nokuba kuyanda amandla kunye nokuqina kweUbhedus okanye ukwandisa ukuqhubela phambili kombane, ukongezwa kweI-calcim-calcium master alloyskuzisa izibonelelo ezininzi kwishishini lokwenza imveliso.

| I-calcium calcium ye-calcium master alloy | |||||||

| Umxholo | Cuca20I-30 okanye ngokwezifiso | ||||||

| Izicelo | I-1. Ii-Hardensirs: Zisetyenziselwa ukondla iipropathi zomzimba kunye noomatshini bokubekwa kwentsimbi. 2. Iingqolowa zokudla okuziinkozo: isetyenziselwa ukulawula ukusasazeka kweekristali zomntu ngamnye kwizinyithi zokuvelisa i-finserm. I-3. Iimodyuli kunye ne-alloys ekhethekileyo: isetyenziselwa ukwandisa amandla, ixesha lokungasebenzi kunye nobisi. | ||||||

| Ezinye iimveliso | I-Cum, Cumg, Cusi, I-CUMUM,Ikomityi, Conke, Cuv, Cani,Cucr, CUF, GECE,Cuas, Cuy, Cuzr, cuhf, cusb, umhle, cula,Cuce, I-cunde, csusm, ityhubhu, njl. | ||||||