I-Tungsten Copper (W-Cu) Nano Allowy powder

I-Nano Tungsten Copper Walloy Allow Power (W-cuI-Alloy Nano Powder) 80nm

Iiparamitha zobugcisa

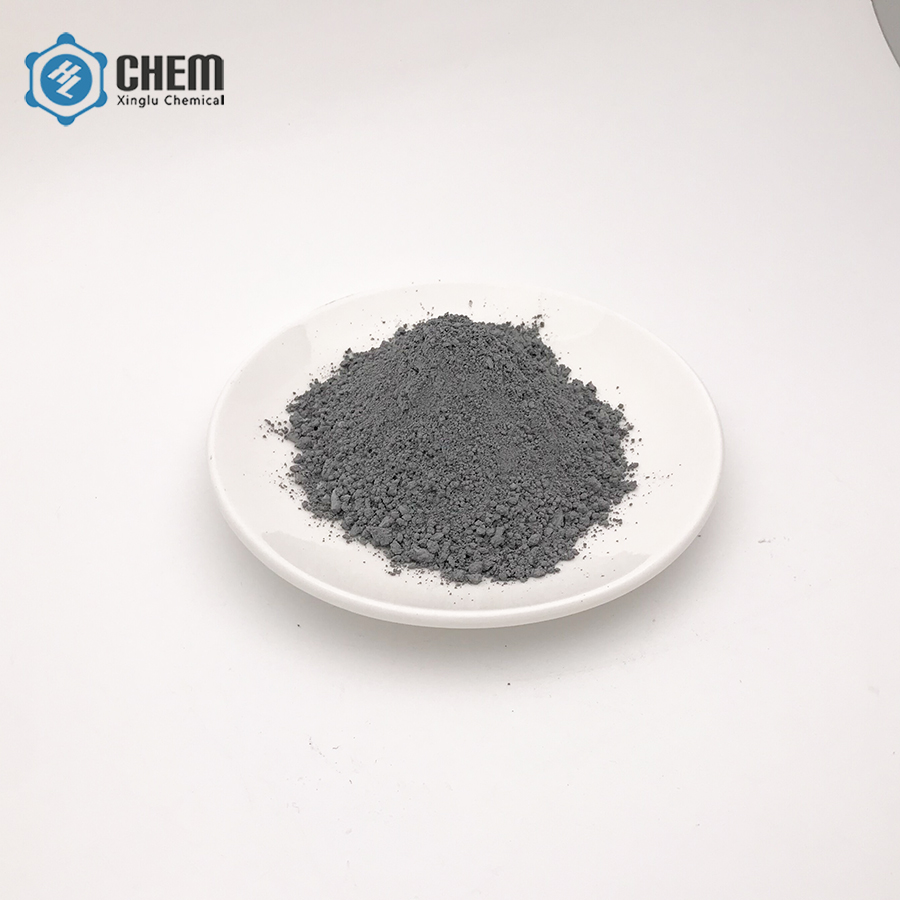

| Imodeli | I-APS (NM) | Ucoceko (%) | Indawo ethile yomphezulu (m2/ g) | Ubunzima beMvolumu (G / CM3) | Ifomu yekristali | Umbala | |

| Nano | I-XL-W-cu-021 | 80 | > 99.6 | 8.02 | I-0.26 | i-spherical | Mnyama |

| Phawula | Inokubonelela ngesabelo esahlukileyo kwiimveliso ze-alloy ngokweemfuno zomthengi | ||||||

Ukusebenza kwemveliso

Indlela eyahlukileyo ye-Laser Ion ye-Ion Ion Inokulungiselela i-Poprict Deameter Damerm I-Copperte Popter, i-Nano ye-Nano, umsebenzi oPhezulu, uhlengahlengiso lwe-CU, i-CUOMIDISIRE. Inokunciphisa kakhulu ubushushu bokufumana kwaye ukunciphisa ixesha lokutya, iMveliso yeMveliso engaphezulu kwe-99%, i-Coander, i-Coander yeMveliso ye-W-Cu15 yeMveliso ye-ON-CUPERS, Ixabiso le-MOTINOFOLOCKINGOLOGNGOLOGNGECROLOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGOLOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGCULOGL inazo izinto ezinobungozi. Kwizinto ezinqabileyo zemveliso ye-Matrix yeMatrix, izixhobo, ukusebenza kakuhle, inxibe ireyithi iphezulu, ixabiso lokulungileyo.

Isikhokelo seSicelo

Izinto ezishushu ezishushu, izixhobo zokuphela kwe-elektroniki eziphezulu, izixhobo zemveliso yemveliso yemveliso yemveliso, iimveliso zobhedu ze-tungsten, izixhobo zonxibelelwano zombane.

Iimeko zokugcina

Le mveliso kufuneka igcinwe yomile, epholileyo netywina kwendalo, ayinakuchazwa komoya, ukongeza kufuneka iphele uxinzelelo olunzima, ngokothutho kwezinto eziqhelekileyo.

Isatifiketi:

Yintoni esinokuyinika: