Phakathi kwee-oxides ezingengo-silidi, i-Aluminiya ineepropathi ezintle, ukuchasana nobushushu obuphezulu, i-Aluminal Aluminisis, i-Arsorch kunye neMihlaba ye-Poreous, i-HodDract kunye neHydrodesity ye-Petroleum eluhlaza Izixhobo.Imicrosoft alumina isetyenziswa ngokufuthi ngokomzi mveliso, kodwa iya kuwuchaphazela ngokuthe ngqo umsebenzi we-Aluminii, inkonzo kunye nokukhetha ikakhulu. Umzekelo, kwinkqubo yokuhlanjululwa kwezithuthi, i-Iposti engafakwanga kwi-Injini ye-Injini iya kwenza i-Coke, eya kukhokelela kwibhloko yeepores ze-catalyst, ngaloo ndlela kunciphisa umsebenzi we-catalyst. I-surfacnty inokusetyenziselwa ukuhlengahlengisa ubume be-Aluminina Carrier ukuba yenze i-ma.improve yayo yokusebenza.

I-Ma inefuthe lokunyanzelwa, kwaye iintsimbi ezisebenzayo zisebenza emva kokuhlawuliswa amaqondo obushushu. Ukongeza, emva kokuhlawuliswa kobushushu obuphezulu, isakhiwo sesobume besiya, i-ma skeleton ikwimo ye-amorphous, kwaye i-acidity engaphezulu ayinakukwazi ukuhlangabezana neemfuno zayo kwicandelo lokusebenza. Unyango lokuhlengahlengiswa luhlala lufuneka luphuculwe umsebenzi obalulekileyo, i-Mesoporaus ye-ridional ye-ridional ye-I.o, i-cuo, i-cuo, i-cuo, i-cu2, njl. Njl.). igcinwe kwi-skeleton.

Uqwalaselo olukhethekileyo lwe-electron kwizinto zomhlaba ezinqabileyo zenza iikhomputer zayo zinezinto ezinqabileyo, zombane kunye nezixhobo ze-fatalytic, izixhobo zefoto, izixhobo ze-adceloptions kunye nezinto zemagnethi kunye nezinto zemagnethi. Izinto ezinqabileyo zomhlaba eziguqulweyo zinokulungelelanisa i-acid (ialkali) ye-Acid (i-Alkali), kunye ne-Alntheses Syntsty Catallyst ye-Nanocrystals ye-nanocrystals kunye nokungazinzanga kwe-catalysts. Kweli phepha, ukuguqulwa komhlaba onqabileyo kunye nokusebenza kwe-MA kuya kwaziswa ukuphucula ukusebenza kwemali, uzinzo lwe-thermal, indawo yokugcina ioksijini, indawo ethile yendawo.

I-1 malungisa

1.1 Ukulungiswa kwe-Aluminizana Carrier

Indlela yokulungiselela i-Aluminii ichaza ulwakhiwo lwayo lwe-Perre, kwaye iindlela zayo zokulungiselela ziquka indlela ye-pseudo-boehmite (PB) yokuphelelwa ngumzimba kunye nendlela ye-sol-gel-ndlela. I-pseudoboehmite (PB) yaqaliswa okokuqala ngcwathi yokufumana i-γ-i-Aloh Colloidal PB ine-interlathel amanzi, eyayingamanzi anamakhono aphezulu ukwenza i-alumina. Ngokwezixhobo ezahlukeneyo ezingafunekiyo, zihlala zahlulwe zaba zendlela ye-cirbhotical kunye ne-chollylauminalum indlela ye-PB ichatshazelwe yi-rystalliedy, kwaye ichaphazeleka kukwanda kwe-crystallity, kwaye ichaphazeleka ziiparamitha zenkqubo.

I-PB idla ngokulungiswa ngokwendlela yokuposa. I-Alkali yongezwa kwisisombululo se-ALUminate okanye i-acid yongezwa kwisisombululo se-Aluminate kwaye i-Alkali i-Alumication), okanye i-Alkali yongezwa kwi-Alumnate Foohydrate, emva koko ihlanjwe, yomiswe kwaye ingabalwa ukufumana i-PB. Eyona ndlela yokulinganisa kulula ukusebenza kwaye iphantsi ngeendleko, ezihlala zisetyenziswa kwimveliso yemizi-mveliso, kodwa iphenjelelwa zizinto ezininzi (isisombululo se-PH, ubushushu, njl njl.). Kwindlela yekharblomis, i-AL (oh) 3is ifunyenwe yindlela yokusabela kwe-CO2AH Naalo2, kwaye i-PB inokufunyanwa emva kokwaluphala. Le ndlela inezibonelelo zokusebenza ngokulula, umgangatho ophezulu, akukho ngcoliseko kunye nexabiso eliphantsi, kwaye linokuyilungiselela i-AluminiiS of Protolytic of Phydrolysis isetyenziselwa ukulungiselela i-PB ecocekileyo. I-Aluminium Alkoxide i-hydrolyzed ukwenza i-aluminium oxide i-monohydrate, emva koko inyangwe ukuze ifumane ubuqhetseba obuphezulu, ubukhulu becala olwenziweyo, ubukhulu becala, kunye nokunyaniseka okukhulu kwamasuntswana aphezulu. Nangona kunjalo, inkqubo inzima, kwaye kunzima ukubuyisa ngenxa yokusetyenziswa kwezinyibilikisi ezithile ezinetyhefu.

Ukongeza, iityuwa ze-inorganic okanye izixhobo zezinto eziphilayo zihlala zisetyenziselwa ukulungiselela i-Alumina Precurs yindlela ye-Sol-Gel, kwaye i-slicks ecocekileyo ilungiselela ukuvelisa isol, evuthuzayo, yomile. Okwangoku, inkqubo yokulungiselela i-Aluminina isaphuculwe kwisiseko sendlela yokuphelelwa yi-PB, kwaye indlela yekharborization iye yeyona ndlela iphambili yoqoqosho lwe-Sol-Gel itsaleleke kakhulu ngenxa yokufumana isicelo seshishini.

1.2 Ukulungiselela

I-Alumina ayinakukwazi ukuhlangabezana neemfuno zomsebenzi, ngoko ke kufuneka ukulungiselela ukusebenza kakuhle ma. Iindlela zeSynthesis zihlala zibandakanya: Indlela yokuphosa i-Nano ngekhabhoni ye-carbon yenziwa njenge template enzima; I-Synthesis ye-SDA: INDLELA YOKUZIPHATHA YENKQUBO YOKUZIPHATHA

1.2.1 Inkqubo ye-EISA

Itemplate ethambileyo isetyenziswa kwimeko ye-acidic, ethi ithintela inkqubo exineneyo neyokugqibela yendlela enzima ye-membrane kwaye inokuqonda ukuqhubeka kwemozulu ye-aperture. Ukulungiswa kwe-MA nge-EISA kutsala ingqalelo enkulu ngenxa yokufumaneka kwayo ngokulula kunye nokuzala kwakhona. Amagqabantshintshi anokwahluka-hlukeneyo anokulungiswa. Ubungakanani be-Porere ye-MO inokuhlengahlengiswa ngokutshintsha i-hydrophobic chain ye-surfaction okanye ihlengahlengise umyinge we-Hydrolysis kwi-Aluminiis ye-Aluminiis ye-Alumina F127, i-Tritethanolamine (iti), njl njl. Ukuphuhliswa kukaMesophasi kwenziwe ngomils

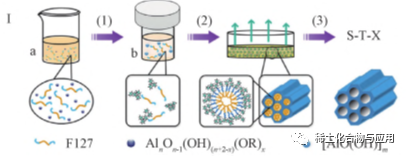

Kwinkqubo ye-EISA, ukusetyenziswa kwezinyibilikisi ezingezozamo (ezinjenge-ethanol) kunye nearhente ze-organol zinokucothisa i-hydrolysis kunye nenqanaba lokuzibandakanya kwe-Oma -um kwaye lingenisa i-alganoum ye-AL (okanye) i-alpropoxide. Nangona kunjalo, kwizinyibilikisi ezingathandekiyo, iitemplate ze-templates zihlala ziphulukana ne-hydrophicicity / hydrophobizetion. Ukongeza, ngenxa yokulibaziseka kwe-hydrolysis kunye ne-polycondetion, imveliso ephakathi ineqela le-hydrophobic, elenza ukuba kube nzima ukunxibelelana netemplate ye-surtiftication. Kuphela kuxa uxinzelelo lwe-surfacnt kunye nenqanaba le-hydrolysis kunye ne-polycondition ye-aluminium ngokuthe ngcembe inyuka ngokuthe ngcembe kwinkqubo yokuphuma kwetemplate ye-Solvent. Ke ngoko, iiparameter ezininzi ezichaphazela iimeko zokuphuma kwamanyibilikisi kunye ne-hydrolysis kunye nendlela yokuphendula i-Hydrolysis kunye neqondo lokushisa, i-sutalyst, iya kuchaphazela isakhiwo sokugqibela sendibano. Njengoko kubonisiwe kwi-Fig. I-1, izixhobo ze-OMA zinozinzo eziphezulu ze-thermal kunye neyona ndlela iphakamileyo yengozi yadityaniswa yi-solvothermal encediswayo kwiNdibano yokuzibandakanya (i-SA-EISA). Unyango lwe-solvothermal lukhuthaza i-hydrolysis epheleleyo ye-Aluminium ye-Aluminium Hydroxyl, eyaphuculwa i-surf -um ye-subroxyl ye-surfroxyl, eyayisenziwa i-suminam yase-suminam yase-Goxagonal yase-Eisa. Kwinkqubo ye-EISA ye-EISA, inkqubo yokuphuma kwe-eldrolysis ye-stdrolysis ye-organouminum, ke iimeko zokuphumeza zinempembelelo ebalulekileyo ekuphenduleni kunye nesakhiwo sokugqibela se-oma. Inyathelo lonyango lwe-solvothermaal likhuthaza i-hydrolysis epheleleyo ye-Aluminium kwaye ivelise ngokuyinxalenye ye-Hydroxyl yama-Aluminum ye-Aluminum ye-Aluminium. Xa kuthelekiswa ne-MA EXELWEYO NGE-EISA YE-EISA YESIBONELELO, I-OMA ilungiselelwe yi-SA-EISA Inendlela ephakamileyo yevolumu, indawo engcono yomphezulu kunye nokuzinza okungcono kwengqondo. Kwixa elizayo, indlela ye-EISA ingasetyenziselwa ukulungiselela i-Uperture enkulu ye-UPERME kunye nenqanaba eliphezulu lokuguqula kunye nokukhetha okuhle ngaphandle kokusebenzisa iarhente ehlaziyiweyo.

Umzobo 1 Ukuhamba kweTshathi ye-SA-EISA ye-SAISA yokuqesha izixhobo ze-OMA

1.2.2 Ezinye iinkqubo

Ukulungiselela okuqhelekileyo kufuna ulawulo olufanelekileyo lweeparamitha ze-synthes ukufezekisa isakhiwo esicacileyo esicacileyo, kwaye ukususwa kwetemplate yeZinto kunzima, nto leyo eyenza inkqubela phambili yenkqubo ye-synthesi. Okwangoku, uninzi lweencwadi zixele i-synthesis ye-ma kunye neetemplate ezahlukeneyo. Kwiminyaka yakutshanje, uphando lujolise ikakhulu kwi-synthesis ye-GLUCOse, i-Sulrose kunye nesitabhisi njenge-I-I-Aluminium ye-Aluminium ye-Aluminium ye-Aluminium ye-Aluminium ye-Aluminium ye-Aluminiyam njengemithombo yealuminiyam. IMa CTab ifunyenwe ngokutshintsha ngokuthe ngqo kwe-PB njenge-Aleminium yomthombo. Ma kunye neepropathi ezahlukeneyo zolwakhiwo, okt Al23) -1, Al23) -2 kunye neAl23and inozinzo oluhle kakhulu. Ukongezwa kwe-surfacntant ayitshintshi ubume be-theristal yendalo ye-PB, kodwa itshintsha indlela eshayileyo yamasuntswana. Ukongeza, ukumiselwa kwe-al2o3-3 yenziwa ngumlinganiso wee-nanopalicles uzinziswe yi-organic slin ye-solven Nangona kunjalo, ubukhulu be-porere osasazwe kwi-al23-1 inqabile kakhulu. Ukongeza, i-Catalys esekwe kwi-Palladium yalungiswa nge-masrier marriers.in methane quations yokuphendula, i-catalyst ixhaswe yi-al22o3-3 yabonisa ukusebenza kakuhle.

Okwesihlandlo sokuqala, ma kunye nokuhanjiswa kobungakanani be-Poll yePoll kulungiselelwe ukusetyenziswa ngexabiso eliphantsi ne-aluminium-etyebileyo ye-Aluminium ye-Aluminium emnyama ye-ABG. Inkqubo yemveliso ibandakanya inkqubo yokukhutshwa kubushushu obuphantsi kunye noxinzelelo oluqhelekileyo. Amasuntswana aqinileyo ashiyekileyo kwindawo yokukhuphela ayiyi kungcolisa indalo, kwaye unokuyiswa ngomngcipheko ophantsi okanye asetyenziswe kwakhona njenge-filler okanye ahlanganisene kwisicelo sekhonkrithi. Indawo ethile yomphezulu we-MAYNTETEREDI i-123 ~ 162m2 / g, ukuhanjiswa kwe-porere inqabile, irakhi ye-Peak yi-0.37 cm3 / g. Umxholo ngu-nano-ubungakanani kunye nobungakanani beekristale malunga ne-11nm. I-synthesis eqinileyo-yombuso yinkqubo entsha yokuqengqesha i-M, enokusetyenziselwa ukuvelisa i-radiachemical abutifchemical absorble yosetyenziso lwekliniki. I-Aluminium Chloride, iAmmonate ye-carbonate kunye ne-Glucose Izixhobo ezihluliweyo zixutywe nomlinganiso we-molar of 1: 1.5: 1.Isivuno se-GATEALY SPREALTION. .

Ukuphelisa, kwixa elizayo, iitemplate ezincinci zemolekyuli zinokuphuhliswa ukwakhiwa kwenqanaba le-Pore-ADD, ihlengahlengise ubume, i-morphologer kunye neempawu zekhemikhali zezixhobo, kwaye zivelise indawo enkulu yomphezulu kwaye i-odole i-Wormush ma. Jonga iitemplate zexabiso eliphantsi kunye nemithombo yealuminium, lungiselela inkqubo ye-synthesi, ucacisa indlela ye-synthesism kwaye ukhokele inkqubo.

Indlela yokuguqula kwe-2 ma

Iindlela zokwenza izinto ezifanayo ezisebenzayo kwi-MA Carriers zibandakanya ukungena, i-Synthe-SIS, i-SIS, i-SIS, i-Ion, ukuDibana koomatshini kunye nokunyibilikisi, phakathi kwazo zombini ezona zisetyenziswayo zisetyenziswayo.

2.1 Indlela ye-Synthesis

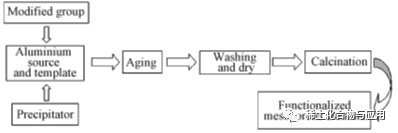

Amaqela asetyenziswayo kulungiso olusebenzayo a longezwa kwinkqubo yokulungiselela ukuba iguqule kwaye uzinze ubume be-skeleton yezinto kwaye uphucule inyathelo lentlekele. Inkqubo iboniswe kwi-2. Liu et al. I-Synthethed Ni / Mo-Al27in inama-P123 njengetemplate. Zombini i-NI kunye ne-MO zasasazeka kwiitekiti ze-odolo Indlela yokukhulisa indawo yokukhula kwi-gamma-al2ssubstict, ethelekiswa ne-γ-al23, i-Mno2-Al2-Al2-Al2-Al2-Al2-Al2-Al2hats ye-BOROPORY SPARORY POTARTURORS. I-Mno2-Al2-Al2 -As Ukusebenza ngokutsha kwe-MNO2-AL2-AL2-AL2O3is kungcono kunelo ye-γ-al2l27o. Uzinzo lweqoko lwezemo kufuneka lusebenze ngakumbi. Ukuphamba, izinto eziguqulweyo ze-MAED zifunyenwe yi-Synthesis elungileyo ye-oda yesakhiwo, ukusebenzisana okuqinileyo phakathi kwamaqela kunye nokudityaniswa kwempahla ka-Aluminina, kwaye akukho lula ukwenza into eninzi yenkqubo yokuphendula kwimeko yesikambulelo.

Umzobo 2 ulungiselelo lwe-MAGORD

I-2.2 indlela yokungena

Ukuntywilisela i-MA kwiqela eliguqulweyo, kunye nokufumana izinto eziguqulweyo emva konyango, ukuze uqonde iziphumo ze-catalysis, i-adsorvotion kunye ne. Cai et al. Ilungiswe i-M ukusuka kwi-P123 yindlela ye-sol-gel, kwaye yambetha e-Ethanol kunye ne-Ethanol kunye neTetrateyenpentamine. Ukongeza, iBelkacesmi et al. I-cubipped kwi-ZcNL 7 inkqubo efanayo yokufumana izixhobo ezi-odolo ze-zinc. Xa kuthelekiswa nendlela ye-Synthesis ye-In-Synthesi, indlela yokungena inesisasazi esingcono, ukusebenza kakuhle kunye nokusebenza okuhle, kodwa amandla onxibelelwano phakathi kwezinto ezisebenzayo kunye ne-Aluminina Carriers ziphazamisekile zizinto zangaphandle.

3 Umsebenzi Inkqubela phambili

I-synthesis ye-Synthesti yomhlaba onqabileyo enepropathi ekhethekileyo yindlela yophuhliso kwixesha elizayo. Okwangoku, zininzi iindlela ze-synthesi. Iiparamitha zenkqubo zichaphazela intsebenzo ye-MA. Indawo ethile yomphezulu, ivolumu ye-pore kunye ne-poreeter ye-PORE ye-MA inokuhlengahlengiswa ngohlobo lwetemplate kunye ne-aluminium precursor. Ukuchonga amaqondo obushushu kunye nethempleti ye-polymer yetemplate ichaphazela indawo ethile yomphezulu kunye nomthamo we-MA. USuzuki kunye neYamauchi wafumanisa ukuba amaqondo obushushu akhawulezayo anyuswa ukusuka kwi-500 ℃ ukuya kwi-900 ℃ .I-aperture inganyuswa kwaye indawo ephezulu incitshisiwe. Ukongeza, unyango olunqabileyo lomhlaba luphucula umsebenzi, uzinzo oluqhelekileyo, uzinzo lwezakhiwo kunye ne-acidity yezakhiwo kwi-ASSORT kwiNkqubo ye-SEATONTOP kwi-REALTION, kwaye ufezekisa uphuhliso lwe-M.

3.1 I-Adsorbent-Adsorbent

I-fluorine emanzini okusela e-China iyonakalisa kakhulu. Ukongeza, ukwanda komxholo we-fluorine kwiSisombululo seShishini leSilc Sulfate siya kukhokelela kwiplate ye-electrode, ukuncipha kwendawo yombane kunye nokwehla kwenkqubo ye-acid yokwenza irhasi yenkomo ye-fluesting ye-fluesting ye-fluesting yenkomo. Okwangoku, indlela ye-adsorction yeyona nto inomdla kwiindlela eziqhelekileyo ze-susarluorioting yemvula. I-carbon evulekileyo, i-amorphous alumina, i-Aluminii isebenza kwaye ezinye ii-adsorbebed zisetyenziselwa ukususwa kwamanzi, kwaye i-Aluminii ye-ADFOME iphezulu kakhulu kwaye ukukhetha i-fluoride kwixabiso le-fluoride, kodwa linqunyelwe ngu Umthamo we-adsorn of fursore, kwaye kuphela kwi-PH <6 Ngaba ingaba ne-Fluortion elungileyo ye-fluoride ye-sloortion. Kundi et al. Ilungisiwe i-Mag enomthamo ophezulu we-luorine ye-luorine ye-62.5 mg / g. Umthamo we-fluorine arsortion of ma phenonongwe kakhulu ziimpawu zalo zokwakha, ezinje ngemimandla ethile, amaqela asebenza kwindawo, ubungakanani be-pore, ubungakanani be-MI yindlela ebaluleke kakhulu yokuphucula ukusebenza kwe-addlon.

Ngenxa ye-acid enzima ye-LA kunye nesisiseko esinzima se-fluorine, kukho ubuchwephesha obuqinileyo phakathi kwe-LA kunye ne-fluorine ion. Kwiminyaka yakutshanje, ezinye izifundo ziye zafumanisa ukuba i-LA njenge-modifier inokuphucula umthamo we-adserside. Nangona kunjalo, ngenxa yokuzinza komhlaba ophantsi komhlaba onqabileyo womhlaba, umhlaba onqabileyo wezinto ezinqabileyo zenziwe kwisisombululo, ezikhokelela ekungcolisweni kwamanzi kunye nengozi yempilo yabantu. Kwelinye icala, ukugxininiswa okuphezulu kwe-aluminium kwindawo yamanzi yenye yezona zityholo zempilo yabantu. Ke ngoko, kuyimfuneko ukuba balungiselele uhlobo lwe-adsorblerblerblerblen enozinzo oluhle kwaye kungabikho sikhukulisekileyo okanye esincinci sezinto ezithile kwinkqubo yokukhupha i-fluorine. I-RIOTIED ye-LA no-CE yayilungiselelwe ngendlela yokungena (i-LE / MA kunye ne-CE / M). I-Adsorbus enqabileyo ilayishwe ngempumelelo kwi-MARTALY YENKONZO YENKQUBO YOKUQHUTYELWA NOKUSETYENZISWA KOMSEBENZI WOKUGQIBELA NOKUGQIBELA Umthamo we-adsorction of i-sleorine, i-LE / MA iqulethe iisayithi ze-hydroxyl ze-hydroxyl, kunye nomthamo we-adsorction ye-F zikumyalelo we-LE / MA> CE / Ma> MI. Ngokwanda koxinzelelo lokuqala, umthamo wokuqala we-sloorine unyuka. Isiphumo se-Adceloption yeyona nto i-5 ~ 9, kunye nenkqubo ye-Adsorsine Comms imodeli ye-I-Langmuir. Ukongeza, ukungcola kwe-ionsfate ii-Ions kwi-Aluminiya kungachaphazela kakhulu umgangatho weesampulu. Nangona uphando olunxulumene nomhlaba olunqabileyo lwe-Aluminii lulungisiwe, uninzi lophando lujolise kwinkqubo ye-adsorbade, i-fuctorine ye-farsorine i-issuratine i-fartorine ye-binc ye-binc yesisombululo se-zinc selc Kwinkqubo ye-chinc hydrometallgergy yenkqubo, kwaye umisele imodeli yolawulo lwenkqubo yokunyanga isisombululo esiphezulu esekwe kwi-run scorker.

3.2 I-Catalyst

3.2.1 Ukutshintsha kowomileyo weMethane

Umhlaba onqabileyo unokuhlengahlengisa i-acidity (isisiseko) sezinto ezityumkileyo, ukwanda kwesithuba seoksijini, kunye nokuqesha i-catalysts ene-catalys enesifo sokusasazeka, ukuzinza kunye nozinzo. Ihlala isetyenziselwa ukuxhasa izinyithi ezihle kwaye iguqule izinyithi ukuya kukhathaza i-metannetion ye-CO2. Okwangoku, umhlaba onqabileyo we-mesoporaught zikhula kwi-Methane yomile (MDR), ukupheliswa kwefoto kunye ne-PD, i-ru, njl. Njl.), I-ru, njl njl. Indleko zeMethane. Nangona kunjalo, ukwenzela i-sourbon kunye ne-carbon ye-nanopalicals kumphezulu we-Ni / Al23lead ukuya kwi-Deactionation ye-Catalyst. Ke ngoko, kunyanzelekile ukuba wongeze i-Aclerawerale, iguqule ithwala i-catalyst kunye nokuphucula indlela yokulungiselela ukuphucula umsebenzi, uzinzo kunye nokunganyangeki kwe-scorch. Ngokubanzi, umhlaba onqabileyo we-oxidey unokusetyenziswa njengezixhasi kunye ne-elektroniki kwi-heterogeneous catalysts, kunye ne-cemo2imigvuli i-NI kwaye iguqula iipropathi ze-inittic ni ngonxibelelwano lwe-metic.

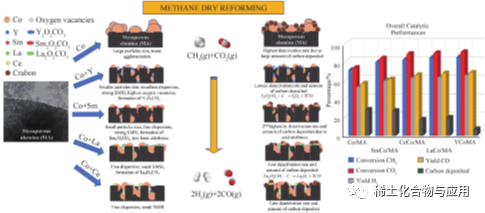

I-MI isetyenziselwa ukomeleza ukusasazeka kwezinyithi, kwaye kunike ukhuseleko kwiintsimbi ezisebenzayo ukuthintela ukwahluka. I-LA2O3WITH IKHANDLA EKHONGE I-OXCHUN YENKCAZO KWI-CARCBON YENKQUBO KWInkqubo yokuguqula, kunye ne-LA2O3POUMPOUTIONOROOROROUMOTION Ukusasazeka kwe-colopoine ye-alumina, enomsebenzi omninzi wokuhlaziya kunye nokomelela. I-LA2O3PEROTER inyusa umsebenzi we-MDR we-CO / I-CO3O4UKESICWANGCISO SOKWENZA ISANGQA NGOKUGQIBELA. Kwinkqubo ye-MDR, unxibelelwano lwe-In-PIT phakathi kweLa2O3and Co2ophaphase, nto leyo eyayibangela ukupheliswa kwe-CXHEY i-CXHEYS ephezulu. I-LA2O3PROmomoyitha ukuncitshiswa kwe-hydrogen ngokubonelela ngoxinano oluphezulu lwe-elektroni kunye nokuphucula izithuba zeoksijini kwi-10% CO / Ma. Ukongezwa kwe-LA2O3reeces i-Interch ebonakalayo ye-Ch4Conptputotion. Ke ngoko, ireyithi yokuguqula ye-Ch4increaded ukuya kwi-93.7% kwi-1073k K. Ukongezwa kwe-LA2OIIROIRPUVUMORK, ikhuthaza ukuncitshiswa kwe-H2, inyuse inani le-HO0 elisebenzayo, lavelisa isithuba esibekiweyo kwi-O03.3%.

I-CE kwaye i-PR yaxhaswa kwi-NI / PR2O3COARTY YOKWENZA INDLELA YOKUZIPHATHA NGOKUGQIBELA Emva kongeza kwaye pr, ukukhetha ukuya kwi-H2INCreaded kunye nokukhetha ukuncipha kwencipha. I-MDR iguqulwe yi-PR yayinobuchule obugqwesileyo, kwaye ukukhetha ukuya kwi-H2INCREED ukusuka kwi-64.5% ukuya kwi-75.6%, ngelixa ukukhetha ukuncipha ukusuka kwi-31.4% Peng Shujing et al. Isetyenziswe ngendlela ye-Sol-gel-ge-i-CEAD-conced mation ilungiselelwe nge-Aluminium Isopropoxide, i-Iyopropanol Solvent kunye neCerium Nitrate Hexahydrate. Indawo ethile yomphezulu wemveliso inyuka kancinci. Ukongezwa kwe-CE kunciphise ukwahlula-hlulwa kwentonga-njenge-nanoparciles kumphezulu we-ma. Ezinye amaqela e-hydroxyl kumphezulu we-γ- al2a3, ngokusisiseko kugutyungelwe ziimpukane. Uzinzo lwe-shirmal ka-MA lwaluphuculwe, kwaye akukho tshintsho lwesigaba sekristal yenzekile emva kwe-1000 ℃ iiyure ezili-10.wang Baowei et al. I-CUO YOKUGQIBELA I-CEO2-AL2-AL24O4BO4BO4BO4by indlela ye-COP. I-Ceo2with i-cubic tic mini encinci yayisasazeka ngendlela efanayo kwi-Aluminii. Emva kokuxhasa i-CEO2-AL2-AL24O4, ukusebenzisana phakathi kwecandelo le-Aluminii kunye ne-COORD COORK NO-MO KUNGUNYUTE NGE-CEO2

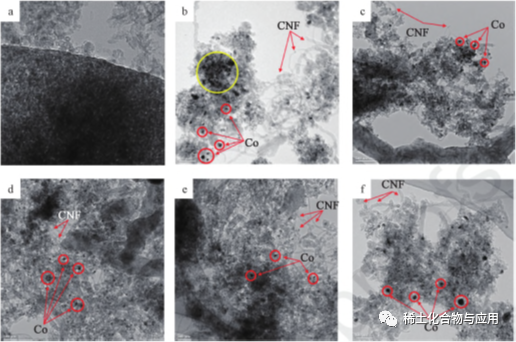

Abantu abanqabileyo emhlabeni (la, C. 3. Ukukhuthaza umhlaba onqabileyo unokuphucula ukusasazeka kwe-CO kwi-Maths kwaye kuthintele i-ageglomeration yamasuntswana e-CO. Incinci ye-paricle, eyomeleleyo kakhulu i-co-mandaight, inobuchule obukhulu kwi-YCO / i-Yeyile kwi-YCO / I-MATARYST, kunye neempembelelo ezilungileyo zabakhuthaza imisebenzi ye-MDR kunye ne-carbon.Fig. I-4 ngumfanekiso we-HRTR emva konyango lwe-MDR nge-1023k, CO2: Ch4: N2 = 1: 1: 1: 2 yeeyure ezi-8. Amasuntswana akhona emotweni yamabala amnyama, ngelixa ii-phars zikhona ngendlela engwevu, exhomekeke kumahluko we-elektroni yoxinaniso. Kumfanekiso we-HRTE nge-10% CO (Maf. 4B), I-Ageglomeration yamasuntswana e-CARRES iqwalaselwe kwi-Carriessongeza amasuntswana anqabileyo kunciphisa amasuntswana e-11. I-YCO / Ma inomnxibelelanisi owomeleleyo, kwaye ukusebenza kwayo kwenkunkuma kubhetele kunezinye izinto. Ukongeza, njengoko kubonisiwe kumakhiwane. I-4b ukuya kwi-4F, i-Shobon Nanon ye-carbon (i-CNF) iveliswa kwi-catalysts, egcina ukunxibelelana negesi kwaye ikhusele eyona nto ikhutshelweyo.

Umzobo o-3 wongezelelo lomhlaba onqabileyo kwiipropathi zomzimba kunye neekhemikhali kunye ne-MDR Consection Persolly ye-CO / Matalyst

3.2.2 I-Deaxidation Catalyst

I-Fe2o3 / Meso-Geal, i-De-De-De-Deachidation Ose-Deadidally, ilungiselelwe ngehlelo le-Oxidative of 1- Outene nge-oxidant ethambileyo, kwaye yasetyenziswa kwi-1,3- i-BDE (BD). I-CE yayichithwa kakhulu kwi-Alumini Matrix, kwaye i-FE2O3 / Meso3 / i-Meso3 / i-Issoest elungileyo ye-I-I-ASTGENS, kodwa inesikhundla esihle se-CO2. Njengoko kubonisiwe kwi-5, imifanekiso kaMing show ibonisa ukuba i-Fe2o3 / Meso-Galare-100 iyasebenza kwaye iyingenelo kwi-Issoct-100 i-CE igcinwe ngempumelelo kwi-Alumna Matrix. Umgangatho wensimo olubalaseleyo obekekileyo wokudibana kwezemigangatho yezinto ezibonakalayo ze-Ultra-Inqanaba lokukhutshwa kweemoto liphuhlise ubume be-pore, uzinzo oluhle lwe-hydrothermal kunye neoksithako enkulu.

3.2.3 Catalyst yezithuthi

I-PD-RH ixhasa i-Alouminam ye-Aluminum enqabileyo ye-Aluminum ye-Alcezriox kunye ne-allazertiox ukufumana izixhobo zokuhamba ngemoto. I-Mesopoindous Aluminium esekwe emhlabeni i-PD-RH / ALC inokusetyenziswa ngempumelelo njengesixhobo sokucoca i-CNG nge-CNG nge-CH4, eyona nto iphambili kwigesi yokuphelisa i-CNG, iphezulu njenge-97.8%. Yamkela indlela yenyoka ye-hydrothermal yokulungiselela loo mbono inqabileyo somhlaba uqonda ukuzibandakanya, yayalela iyunithi ye-Protors ehambelana ne-Pocurstance ye-Point-Post ye-AutoMoble Esplence Sport-gost.

Imifanekiso ye-4 ye-HRTE ye-Ma (a), CO / Ma (B), i-LACO / Ma (C), i-CECO / Y) kunye ne-sco / ma (f)

Umzobo 5 Umfanekiso we-5 MECE (a) noDiam wezinto ze-EDS (B, C) we-fe2o3 / meso-cel-100

3.3 Ukusebenza okukhanyayo

Ii-elektroni zezinto ezinqabileyo zomhlaba zinovuyo ngokulula kwinguqu yamanqanaba ahlukeneyo amandla kwaye ukhanyise ukukhanya. I-ion enqabileyo yomhlaba ihlala isetyenziswa njengokuthabathayo ukulungiselela izixhobo ze-LUMORT. Rare earth ions can be loaded on the surface of aluminum phosphate hollow microspheres by coprecipitation method and ion exchange method, and luminescent materials AlPO4∶RE(La,Ce,Pr,Nd) can be prepared. I-LUMOVCect Wavenct ikwingingqi ekufutshane. Ezi zixhobo zininzi iifilimu zendlela eqinisekileyo yobude obucacileyo, ke kuyimfuneko ukulawula isalathiso sokuqaqamba kunye nobungqingqwa, i-tirconium dioxide kunye ne-silicoxier ye-tiorcon kunye nesalathiso esisezantsi sihlala sisetyenziselwa ukulungisa kwaye sakha ezo zixhobo. Uluhlu lokufumaneka kwezixhobo ezinepropathi yemikhamikhali eyahlukeneyo iyandiswa, eyenza ukuba ikwazi ukuyila ii-Photon zenzwa. Ukuqaliswa kwe-MA kunye ne-OxyyDhyDroxide Friftide Izixhobo ze-Optical zibonisa amandla amakhulu kuba isalathiso se-Reflen sifana ne-silicon dioksi.but iipropathi zekhemikhali zahlukile.

3.4 Uzinzo lwe-thermal

Ngokwanda kweqondo lobushushu, ukona kuchaphazela kakhulu isiphumo sokusetyenziswa kwe-matalyst, kwaye indawo ethile yomhlaba inciphisa kwaye i-γ-al-Al2in Crystalline iguqule kwi-δ kunye ne-θ ukuya kwi-prostase. Izixhobo zomhlaba ezinqabileyo zinozinzo ezifanelekileyo kunye nozinzo oluqhelekileyo, ukuziqhelanisa okuphezulu, kwaye zifumaneka ngokulula kwaye ziphantsi kwezinto ezingaphantsi. Ukongezwa kweempawu zomhlaba ezinqabileyo kunokuphucula ukuzinza kwe-thermal, ubushushu obuphezulu obuphezulu kunye neepropathi zoomatshini bomphathi, kunye nokulungelelanisa i-acidicy ye-carriers.la kunye nezona zinto zisetyenziswayo. ULuigrang nabanye bafumanise ukuba ukongezwa kwezinto ezinqabileyo zomhlaba ngokufanelekileyo kuthintele ukwaliwa kwee-alkroxyl, i-LA kunye notshintsho lwenkunkuma, kwaye inciphise umonakalo weqondo lobushushu. I-Alumina elungiselelwe i-Alumina iseyindawo ephezulu yendawo kunye nevolumu ye-pore. Li yanqiu et al. Yongezwe i-5% LA2O3TO γ-al23O3, ephucule uzinzo lwe-shirm kunye nokwandisa ivolumu ye-pore kunye nendawo ethile yendawo ye-Aluminina. Njengoko kunokubonwa kumzobo 6, i-LA2O3DED ukuya kwi-γ-al23o3, phucula uzinzo lwe-thermal womhlaba onqabileyo.

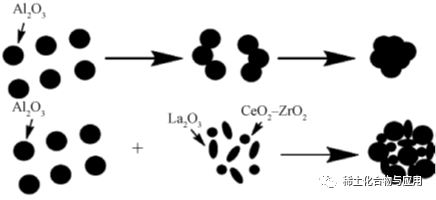

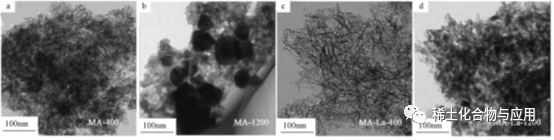

Kwinkqubo yokudlala amasuntswana e-nano enombala o-la ukuya kwi-ma, indawo yokubheja kunye nethamo le-Poure ye-MA-la xa i-HATE COUTE YOKWENZA IXESHA LOKUGQIBELA LOKUGQIBELA. njengoko kubonisiwe kwi-Fig. 7, Ukonyuka kwamaqondo obushushu, i-LA inqanda indlela yokukhula kwengqolowa kunye nenqanaba lotshintsho, ngelixa amakhiwane. I-7a kunye ne-7c bonisa ukuqokelelwa kwamasuntswana eNano-from. kwi-Fig. I-7b yobukhulu bamasuntswana amakhulu eveliswe ngokuhlawuliswa kwi-1200 ℃ imalunga ne-100nm.it iphawula ukuthungwa kwe-MA. Ukongeza, xa kuthelekiswa ne-MA-1200, i-Ma-la-1200 ayikhathaleli emva konyango lobushushu. Ukongezwa kwe-LA, i-nano-fibers amasuntswana anobuchule obungcono. Nokuba kubushushu obuphezulu bokuchonga amaqondo obushushu, i-LA ye-Doped isasasazeka kakhulu kumphezulu we-ma. I-LA iguqulwe Manze isetyenziswa njengomthwali we-PD ukuthathwa kwe-C3H8OXIDEATION.

Umzobo 6 Wesakhiwo

Fig. 7 I-GEE-400 (a), Ma-1200 (B), i-Ma-la-la-la-1200 (D) kunye ne-Ma-1200 (D)

4 ISIQINISEKISO

Inkqubela phambili yokulungiselela kunye nokusebenza okusebenzayo komhlaba onqabileyo we-MAGCIDS waziswa. I-FARD WARTAGORD Isetyenziswe ngokubanzi. Nangona uphando oluninzi lwenziwe kwisicelo esisekenzini, uzinzo lobushushu kunye ne-adsorction, izixhobo ezininzi zineendleko eziphezulu, i-Dect ephantsi, i-oda engalunganga kwaye kunzima ukubakho kwezommiselo. Oku kulandelayo kufuneka kwenziwe kwixa elizayo: Khusela ubume kunye nolwakhiwo lomhlaba onqabileyo Ukuseka imodeli yolawulo lwenkqubo esekwe kwinkqubo yokusebenza yokunciphisa iindleko kwaye iqonde imveliso yezommiselo; Ukwenzela ukwandiswa kwezibonelelo zomhlaba onqabileyo wase China, kufuneka siphonononge indlela yolungiso lomhlaba onqabileyo, ukuphucula ingcalulo kunye nenkqubo yokulungiselela umhlaba onqabileyo we-MA.

Iprojekthi yeNgxowa-mali: Inzululwazi yeShaanze kunye neTekhnoloji Jikelele iProjekthi yoVavanyo (i-2011ktdz01-04-01); IPhondo leShaaANxi Iphondo ngo-2019 IProjekthi efanelekileyo yoPhando (i-19JK0490); 20200 IPHULO LOKUFUNDA LWEZIKOLO EZIQHELEKILEYO IKholeji yeHuaq, Xi 'iYunivesithi yoYilo loYilo kunye neTekhnoloji (20ky02)

Umthombo: Umhlaba oDlalayo

IXESHA LOKUQALA: Jun-15 ukuya ku-1221