Ukusetyenziswa kweumhlaba onqabileyoEkuphoseni i-aluminium alloy yenziwa ngaphambili kwelinye ilizwe. Nangona i-China yaqala uphando kunye nokusetyenziswa kwalo mxholo ngonyaka ka-1960, kuye kwaphuhliswa ngokukhawuleza. Umsebenzi omninzi wenziwe ngocaphucalulo loPhando lokuSebenza, kwaye ezinye izinto eziphunyeziweyo zenziwe. Izinto zokugcina izinto zeHydrogen, njl.

◆◆ Intshukumo yomhlaba onqabileyo kwiAluminiyam neAluminiyam Allo Allo Allo Allo Allo

Umhlaba onqabileyo unemichiza ephezulu, amandla aphantsi kunye nolungiselelo olukhethekileyo lwe-elektroni, kwaye unokunxibelelana nabantu ngezinto ezisetyenziswayo.Rare ezisetyenziswa ngokuqhelekileyo kwi-Aluminium kunye ne-Aluminium ALLYS ibandakanya i-LA (i-lanthanum), CE (i-cerium), Y (yttrium) kunye ne-SC (Isikali). Zihlala zongezwa kwi-alminium fluiers ineemodyuli, iiarhente zokucoca kunye neearhente zokudimanisa, ezinokucoca inyibilike, ziphucule inkohliso, njl.

01Ukuhlanjululwa komhlaba onqabileyo

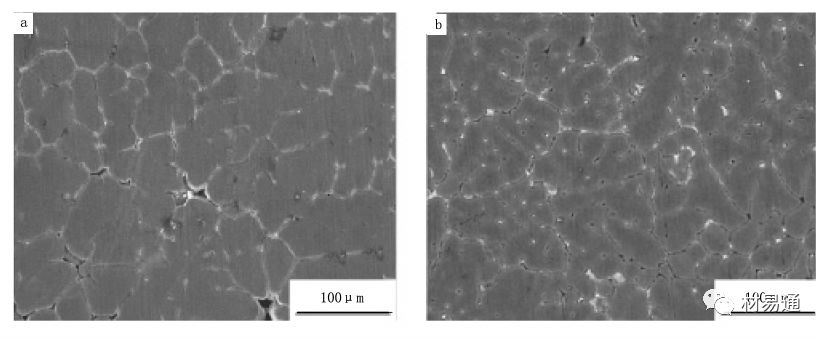

Njengesixa esikhulu segesi kunye ne-oxide igalelo (ikakhulu i-hydrogen, i-nitrogen ye-Aluminium Allow. i-aluminium, ukuncitshiswa kwenqanaba le-pinhole kunye ne-pinsity (jonga umfanekiso 1B), kunye nokuncitshiswa kwe-hydrogen, oko kukuthintela i-Hydrogen, oko kukuthintela i-Hydrogen, i-Aluminiman; umhlaba onqabileyo kunye ne-nitrogen Ifom yokuphinda icocwe, esuswa kakhulu ngendlela ye-Slag kwinkqubo yokunyibilika, ukufezekisa injongo yokucoca ulwelo lwealuminium.

Ukuziqhelanisa kubonakalise ukuba umhlaba onqabileyo unefuthe lokunciphisa umxholo we-hydrogen, ioksijini kunye ne-sulfuge kwi-aluminium kunye ne-Aluminium Alfs. Ukongeza i-0.1% ~ 0.3% i-Aluminum Ulwelo luncedo ngakumbi ukususa izinto ezingcolileyo, ukuguqula i-morphology ye-bilings, ukuguquguquka, kunye nokusasazeka komhlaba, kunye nokusasazeka, kwaye kungancitshiswa ukwenza i-slag kwaye isusiwe, ngaloo ndlela ihlambulule ulwelo lwe-aluminium; amasuntswana amahle aseleyo abe yi-nuclei ye-aluminium yokuphucula ii-Grains.

Umzobo 1 sem morphology we-7075 Alloty ngaphandle kwe-PER kunye ne-W (re) = 0.3%

a. Akenziwa; b. Yongeza i-W (re) = 0.3%

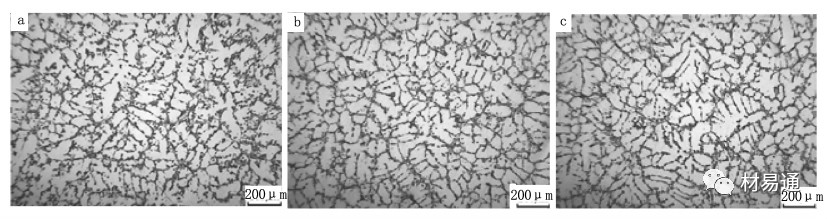

02I-Metamorphism yomhlaba onqabileyo

Utshintsho lomhlaba olunqabileyo lubonakaliswa ikakhulu ekuhlaziyeni iinkozo kunye nodonga, ukubonakala kwenqanaba le-Coardes, cima inqaku le-right kunye ne-radius ye-Alumnum Astom, kwaye Iipropathi ziyasebenza. Ukunyibilikisa ulwelo lwe-aluminium kulula kakhulu ukugcwalisa isiphene senqanaba le-alloy, enciphisa uxinzelelo oluthile kwi-Gecle ePrit kunye ne-MOLE eSebenzayo, kwaye ikwazi ukuphucula isakhiwo se-ALTECY (jonga umfanekiso 2b).

Umzobo 2 Ubume be-2

a. I-dosage resuge ngu-0; b. Ukongeza yi-0.3%; c. Ukongeza i-0.7%

Emva kokongeza izinto ezinqabileyo zomhlaba ze (Al) zenqanaba laqalisa ukuba lincinci, elidlale indima ehlaziyiweyo yomhlaba onqabileyo. Kubushushu obuphezulu kangangexesha elithile, umhlaba onqabileyo uya kudlala le ndima enkulu kwi-Metamorphism.In, i-nuclei ye-nuclei ye-numcle ye-numonds ibonisa ukuba umhlaba onqabileyo we-Aluminium Alloy.

03 Isiphumo se-microAllous yomhlaba onqabileyo

Umhlaba onqabileyo ukhona kwi-aluminium kunye ne-aluminium ye-Aflimes kwiifom ezintathu: Isisombululo esiqinileyo kwi-Aluminiyam Alwiry, isisombululo esongezelelekileyo someleza umda onqabileyo, ukuqiniswa kwesigaba senqanaba lesibini lomhlaba onqabileyo.

Ubukho bomhlaba onqabileyo kwi-Aluminium kunye ne-Aluminium Alloy inxulumene nexabiso elisondeleyo kwimali yokongeza. Ngokubanzi, xa umxholo kwakhona ungaphantsi kwe-0.1%, indima yenkozo eyomeleza eyomeleza, i-rod ye-rod, i-RODS, i-SPREARD ye-SPREARDS, eya kuthi ivelise i-sprieds, eyasasaza imithombo yomhlaba. ukuqiniswa kwesigaba sesibini.

◆ ◆ Chaza umhlaba onqabileyo kwipropathi ye-aluminium kunye ne-aluminium alloy ◆◆

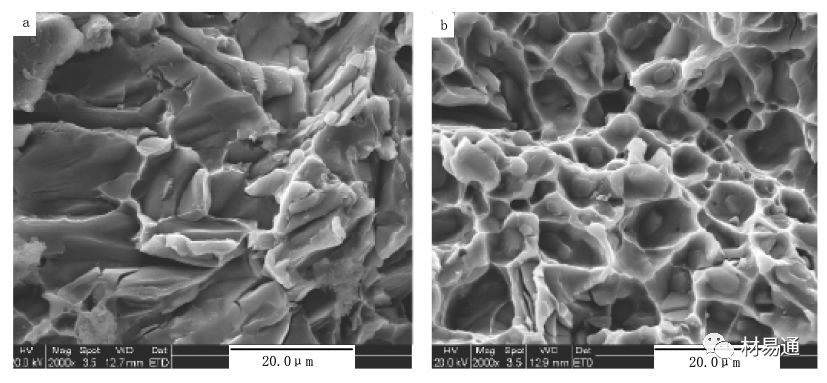

01 Iziphumo zomhlaba onqabileyo kwiipropathi ezibanzi ze-alloy

Amandla, ubukhali, ubuchule obuthile, banxibe ukunganyangeki kunye nezinye iipropathi ezinobuchule be-alloy zingaphuculwa ngokongeza isixa esifanelekileyo somhlaba onqabileyo.0.3%bukusuka kwi-205.9 MPA ukuya kwi-274 MPA, kunye ne-HB ukusuka kwi-80 ukuya kwi-108; yongeza i-0.42% ye-SC ukuya kwi-7005 Aloyσbinyuke ukusuka kwi-314MPA ukuya kwi-414MPA, σI-0.2Inyuke ukusuka kwi-282MPA ukuya kwi-378MPA, iplastiki inyuke ukusuka kwi-6.8% ukuya kwi-10.1%, kunye nokuzinza kobushushu obuphezulu kwakuphuculwa kakhulu; Ukongeza i-0.14% ~ 0.64% LA kwi-Al-6MG-0MG-0Mn Allocy inyusa ukuba i-Allous ye-Alloy ibonisa ukuba ukongeza isixa esifanelekileyo seSC.Fig. I-3 ibonisa ukubonakala kwe-sem ye-tensle types ye-al-Si7-mg0.8I-Alloy, ebonisa ukuba yindlela eqhelekileyo ye-bricavity ye-brittle eqhekekileyo ngaphandle kwe-RE, ngelixa emva kwe-0.3% yongezwa, i-Dimple Swiple ivela ekuqhekekeni, oko kubonisa ukuba inamandla kunye nexesha elifanelekileyo.

Umzobo o-3 qunsle of morphology

a. Ayijoyinanga; b. Yongeza i-0.3% re

02Iziphumo zomhlaba onqabileyo kubushushu obuphezulu beepropathi ze-alloys

Ukongeza inani elithile leumhlaba onqabileyoKwi-Aluminium Alloy inokuphucula ngokufanelekileyo ubushushu obukhulu bokunganyangeki kwe-allouy. inokuphucula iipropathi eziphezulu zobushushu ze-alloys; i-al4% ye-AL-3.4% CE Allow Allow Allow Allow;3Amasuntswana amasuntswana ekungekho lula ukuba aphathe amaqondo obushushu kunye ne-matrix ethoba umda wokudla okuziinkozo, kwaye uphucula kakhulu ipropathi yobushushu be-alloy.

03 Iziphumo zomhlaba onqabileyo kwiipropathi ze-alfays ze-alloys

Ukongeza umhlaba onqabileyo kwi-Aluminium Alloty kunokutshintsha ubume befilimu ye-oxide, i-0,2% i-063; xa i-0.1% i-0,2% i-0,2% ye-0,2% ifumana i-ALMG ye-AlG Allow Alf i-Allow Allow kunye nokuQeqwa kweGlowayo.

04 Iziphumo zomhlaba onqabileyo kwiipropathi zombane ze-alloys

Ukongeza i-Aluminiity Aluminiity iyenzakalisayo ekusebenzeni, kodwa ukuqhubela kunokuphuculwa ukuya kwinqanaba elithile le-Aluminium enqabileyo. alloy, which has been adopted by most domestic wire factories;Add trace rare earth to high-purity aluminum to make Al RE foil capacitor. Xa isetyenziswa kwiimveliso ezingama-25KV, i-Indet ye-AKICITATITIT iphindwe kabini, ivolumu nganye yeyunithi incitshisiwe ngama-47%, kwaye ivolumu yeCacecisiwe kakhulu.

05Iziphumo zomhlaba onqabileyo kwi-intersosion ye-allosion ye-alloy

Kwezinye iindawo zenkonzo, ngakumbi phambi kwe-ion ye-chloride, izabelo zisengozini, i-Crevice I-Corrosion kunye ne-Corrosion kunye ne-Corrosion ye-Corrosion kunye ne-Corrosion kunye ne-Corrosion kunye ne-Corrosion kunye ne-Corrosion kunye noku-odole ukunyangwa kwe-allosion ye-alloys, izifundo ezininzi zenziwe. Kufunyanwa ukuba ukongeza inani elifanelekileyo lomhlaba onqabileyo ukuya kwi-Alluminiyam Alfmes anokuphucula ngokufanelekileyo ukuxhaphaza kwabo umhlaba (0.1% 0.5%) kwi-Aluminiyam yeminyaka emithathu ilandelelana. Iziphumo zibonisa ukuba ukongeza inani elincinci lendawo enqabileyo kwi-aluminium kunokuphucula ukumelana ne-aluminium, kunye ne-Comrosion Doumater Programment (e-LE,. I-2024 ALTY, yenza umphezulu we-elektrode ye-Aluminium ethambekele ukuba iyunifomu ye-Alrosion kunye ne-Loumin Allows inokuphucula ukusebenza kwe-Allousion ye-Allousion inokuphucula ukusebenza kweqondo lobushushu, ukuqina komoya kunye nokunganyangeki komoya yezabelo, ezisetyenziswa ngokubanzi njengezixhobo ze-aerospace.

◆ Itekhnoloji yokulungiselela i-Aluminiyam yolwaluko

Umhlaba onqabileyo wongezwa ngohlobo lwezinto zokulandelela kwi-allomim alloys kunye nezinye izabelo. Umhlaba onqabileyo unemichiza ephezulu yemichiza, inqaku eliphezulu lokunyibilika, kwaye kulula ukuba i-zungud kwaye itshiswe kumaqondo obushushu aphezulu. Oku kubangele ubunzima obuthile ekulungiseleleni nasekusebenziseni uphando olunqabileyo lomhlaba.

01 Indlela yokuxuba

Indlela yokunyibilikisa exubeneyo kukongeza umhlaba onqabileyo okanye umxube wentsimbi yomhlaba onqabileyo kwi-Aluminiyam i-Aluminum ye-Aluminiyam ye-Aloul Alroloy okanye i-Aloumy ye-Alloum, i-Aluminiyam esele ikhuthazekile.

02 I-electrolysis

Indlela yokutsala ityuwa ye-Ectten encrolysis kukongeza i-oxide ye-oxide okanye umhlaba onqabileyo kwi-Aluminium Alloud Alloud Alloud Alloud Alloud. Ngokubanzi, zimbini iindlela, ezizezi, ukuba, indlela ye-casede ye-casede kunye nendlela ye-elektroniki ye-elektroniki. Okwangoku, sele iphuhlisiwe ukuba imihlaba enqabileyo yomhlaba inokulongezwa ngokuthe ngqo kwiiseli zombane ezomeleleyo ze-Aluminium, kwaye i-Alrows enqabileyo ye-allominum ingaveliswa nge-elektrolysis ye-eltide ye-piloride yendlela ye-chloride.

03 Indlela yokuNcitshiswa kwe-Alweunothermic

Kungenxa yokuba i-Aluminium inesiseko esiqinileyo sokunciphisa, kwaye i-aluminium inokubangela iintlobo ezahlukeneyo ze-iares, i-aluminium zingasetyenziswa njenge-Armment Real Allos Alloss.Ikati yekhemikhali iboniswe kule foalaula ye-aluminum:

RE2O3+ 6A-→ 2real2+ Al2O3

Phakathi kwawo, i-oxide oxide okanye umhlaba onqabileyo unokusetyenziswa njengezixhobo ezinqabileyo ze-alwilinum, kwi-slicn aluminum. Indlela. Kubushushu obuphantsi (780 ℃), ukuncitshiswa kwe-aldinormic kugqityiwe kwinkqubo ye-Sodium Bluoride kunye ne-sodium hlorind, ethi inokuthintela iingxaki ezibangelwa bubushushu obuphezulu.

◆ ◆ ◆ Inkqubela phambili ye-Aluminum enqabileyo yomhlaba onqabileyo

01 Ukusetyenziswa kwe-Aluminium yomhlaba onqabileyo kwimveliso yamandla

Ngenxa yeenzuzo zokusebenza kakuhle, amandla amakhulu okuphefumla, amandla aphezulu, ukunxiba i-Alloud ye-Alloy ye-Al-Allous Alloy ye-Al-Alloy ye-Al-Alloy ye-Aluminium yi-Allow Plation enomxholo ophezulu, onayo Impembelelo enkulu kwizikhundla zombane. Ukongeza inani elifanelekileyo lomhlaba onqabileyo unokuphucula i-morphology ekhoyo kunye nokusasazwa kwe-silicon kwi-Aloul Alfrium okanye i-Yourrium ye-Aluminium okanye i-Wttrium enqabileyo ye-altrium; Inkqubo yeAluminium Alminum. Iintambo nabaqhubi ezenziwe nge-Aluminiyam yomhlaba onqabileyo base-Alloum onokongeza ixesha lecable kwaye kwandise ubomi benkonzo yeentambo.

02Ukusetyenziswa kwe-Aluminiyam yomhlaba onqabileyo kwimveliso yokwakha

I-6063 Aluminium Alloy yeyona isetyenziswa kakhulu kwishishini lokwakha. Ukongeza i-0.15% 0.25% Umhlaba onqabileyo unokuphucula kakhulu indawo yokusebenza, kwaye unokuphucula i-Aluminium ye-Aluminium, umda wonyango, kwaye uchithekile kwimimandla ye Ifomu yemilinganiselo yokuphucula isakhiwo kunye neengqolowa, ukuze ubungakanani bendawo yokudakumba kunye nobungakanani bayo buye baphuculwa kakhulu, ukuze usasazwe lunyuke kakhulu kwidigri eyahlukeneyo. Umzekelo, amandla eprofayili anyuswa ngaphezulu kwe-20%, i-elongwetion inyuswe nge-50%, kwaye izinga le-corrosion lincitshiswa ngaphezulu kwe-5% ~ ~ 8%, kwaye ipropathi enombala isetyenzisiwe.

03Ukusetyenziswa kwe-Aluminium yomhlaba onqabileyo kwimveliso yemihla ngemihla

Ukongeza umkhondo onqabileyo kwi-Aluminium ecocekileyo ye-Aluminium ye-Aluminum yeemveliso zemihla ngemihla, ukuhambisa iipleyiti ze-aluminium. I-Alfay ye-alloy ingaphezulu kokunganyangeki kabini, i-10% ye-15% ye-10% yonyusa i-Aluminium ye-Aluminium ithelekiswa kakhulu, kwaye ithengiswa kakhulu, kwaye ithengiswa kakuhle kwiimarike zasekhaya nezangaphandle.

04 Ukusetyenziswa kwe-Aluminium yomhlaba onqabileyo yeAluminum kwezinye iinkalo

Ukongeza amawaka amawaka omhlaba onqabileyo ngowona nguqulelo ye-al tering ye-al e-al Uninzi lweempawu zemveliso zisetyenzisiwe kwinqwelomoya, iinqanawa, ii-onjilmobles, iimoto zediscys, i-piston, i-piston, i-piston, i-piston, isixhobo kunye nezona zixhobo ze-Aluminium. Inesisasazi esomeleleyo sokuqiniswa, ukulungisa okuzinzileyo komeleza, isisombululo esomeleza iziphumo ze-Aluminiyam, kwaye zinokuphucula amandla, ukuxhaphaza, iimoto eziphezulu, iimoto eziphezulu, njl.njl. I-Aluminium Allo ephuhliswe yi-NASA inamandla aphezulu kunye nobushushu obuphezulu kunye nokuzinza kweqondo lobushushu olusezantsi kwaye kusetyenziswe iinxalenye zenqwelomoya kunye neenqwelomoya.

Kwi-GOGUST kwi-GOGUST YOMBULELO YABADLALI NGE-WANG Hui, Yang And And Qi

IXESHA LOKUQALA: UJUL-05-2023