Iyintoni impembelelo yeeoksidi zomhlaba ezinqabileyo kwiingubo zeeramic?

I-Ceramics, imathiriyeli yesinyithi kunye nemathiriyeli yepolymer zidweliswe njengezinto ezintathu eziphambili eziqinileyo. I-Ceramic ineepropathi ezininzi ezigqwesileyo, ezinjengokumelana nobushushu obuphezulu, ukuxhathisa ukubola, ukuxhathisa ukunxiba, njl., kuba imowudi ye-atom yokudibanisa kwi-ceramic yi-ionic bond, ibhondi edibeneyo okanye ibhondi edibeneyo ye-ion-covalent enamandla amakhulu ebhondi. Ukwaleka kweCeramic kunokutshintsha inkangeleko, ulwakhiwo kunye nokusebenza komphandle we-substrate,I-Coating-substrate composite iyathandwa ngenxa yokusebenza kwayo okutsha. Iyakwazi ukudibanisa ngokwendalo iimpawu zokuqala ze-substrate kunye neempawu zokumelana nobushushu obuphezulu, ukumelana nokunxiba okuphezulu kunye nokumelana okuphezulu kwe-corrosion ye-ceramic, kwaye inike umdlalo opheleleyo kwiingenelo ezibanzi zeentlobo ezimbini zezixhobo, ngoko isetyenziswa ngokubanzi kwi-aerospace. , inqwelomoya, ukhuselo lwesizwe, ishishini lemichiza kunye namanye amashishini.

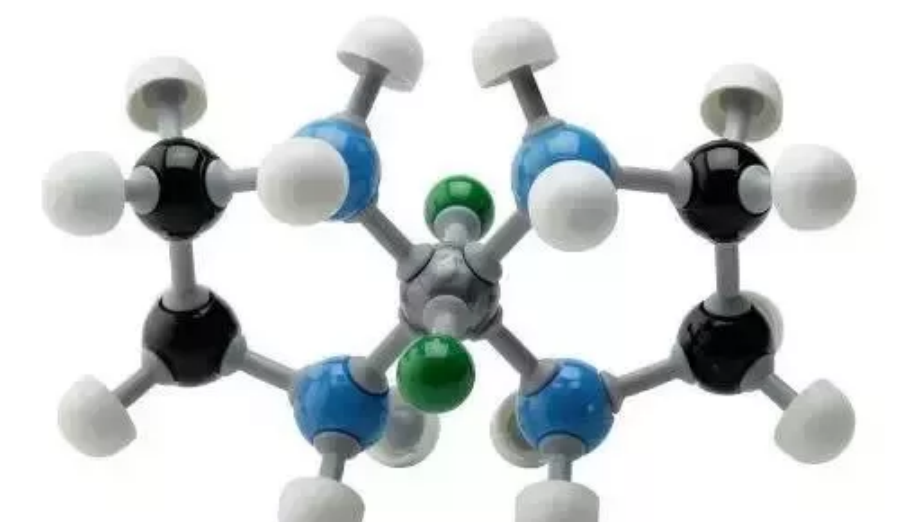

Umhlaba onqabileyo ubizwa ngokuba "yindlu yobuncwane" bezinto ezintsha, ngenxa yesakhiwo salo sombane esikhethekileyo se-4f kunye neempawu zomzimba kunye neekhemikhali. Nangona kunjalo, iintsimbi ezicocekileyo zomhlaba ezinqabileyo azifane zisetyenziswe ngokuthe ngqo kuphando, kwaye iikhompawundi zomhlaba ezinqabileyo zisetyenziswa kakhulu. Iikhompawundi eziqhelekileyo ziyi-CeO2, i-La2O3, i-Y2O3, i-LaF3, i-CeF, i-CeS kunye ne-ferrosilicon enqabileyo yomhlaba.Ezi zixhobo ezinqabileyo zomhlaba zinokuphucula isakhiwo kunye neempawu ze-ceramics kunye neengubo ze-ceramic.

Ndifaka iioksidi zomhlaba ezinqabileyo kwizinto ze-ceramic

Ukongeza izinto ezinqabileyo zomhlaba njengezizinzisi kunye ne-AIDS ye-sintering kwii-ceramics ezahlukeneyo kunokunciphisa ubushushu be-sintering, ukuphucula amandla kunye nokuqina kwezinye ii-ceramics zesakhiwo, kwaye ngoko ukunciphisa iindleko zemveliso. Kwangaxeshanye, izinto ezinqabileyo zomhlaba nazo zidlala indima ebaluleke kakhulu kwizinzwa zegesi ye-semiconductor, imidiya ye-microwave, i-piezoelectric ceramics kunye nezinye ii-ceramics ezisebenzayo. Uphando lufumanise ukuba, Ukongeza ezimbini okanye ngaphezulu iioksidi zomhlaba ezinqabileyo kwi-alumina ceramics kunye kungcono kunokongeza i-oksidi yomhlaba enye enqabileyo kwi-alumina ceramics. Emva kovavanyo lokuphucula, i-Y2O3 + CeO2 inesiphumo esihle. Xa i-0.2% Y2O3 + 0.2% CeO2 yongezwa kwi-1490℃, ukuxinwa kweesampuli ze-sintered zingafikelela kwi-96.2%, edlula ubuninzi beesampuli kunye nayo nayiphi na i-oxide yomhlaba enqabileyo i-Y2O3 okanye i-CeO2 yodwa.

Umphumo weLa2O3 + Y2O3, i-Sm2O3 + La2O3 ekukhuthazeni i-sintering ingcono kunokongeza i-La2O3 kuphela, kwaye ukuchasana kokugqoka kuphuculwe ngokucacileyo. Kwakhona kubonisa ukuba ukuxutywa kwee-oksidi ezimbini ezinqabileyo zomhlaba akukona ukongezwa okulula, kodwa kukho intsebenziswano phakathi kwabo, enenzuzo ngakumbi kwi-sintering kunye nokuphuculwa komsebenzi we-alumina ceramics, kodwa umgaqo uhlala ufundwa.

Ukongeza, kufumaniseke ukuba ukongezwa kwee-oxide zetsimbi ezinqabileyo zomhlaba ezixubileyo njenge-AIDS ye-sintering kunokuphucula ukufuduka kwezinto, ukukhuthaza ukufakwa kwee-ceramics ze-MgO kunye nokuphucula ukuxinana. Nangona kunjalo, xa umxholo we-oxide yensimbi edibeneyo ingaphezulu kwe-15%, ukuxinana okuhlobene kuncipha kwaye i-porosity evulekile iyanda.

Okwesibini, impembelelo yee-oxides zomhlaba ezinqabileyo kwiipropati zeengubo ze-ceramic

Uphando olukhoyo lubonisa ukuba izinto ezinqabileyo zomhlaba zinokucokisa ubungakanani beenkozo, zandise ukuxinana, ziphucule i-microstructure kunye nokucoca ujongano. Idlala indima ekhethekileyo ekuphuculeni amandla, ukuqina, ukuqina, ukuxhathisa ukunxiba kunye nokumelana nokugqwala kweengubo ze-ceramic, eziphucula ukusebenza kweengubo ze-ceramic ukuya kumlinganiselo othile kunye nokwandisa uluhlu lwesicelo se-ceramic coatings.

1

Ukuphuculwa kweempawu zemishini yeengubo zeeramic ngee-oxides zomhlaba ezinqabileyo

Iioksidi zomhlaba ezinqabileyo zinokuphucula ngokubonakalayo ubulukhuni, amandla okugoba kunye nokomelela kokuqina kwekhonkco leengubo zeceramic. Iziphumo zovavanyo zibonisa ukuba amandla e-tensile yokwambathisa anokuphuculwa ngokufanelekileyo ngokusebenzisa iLao _ 2 njengesongezo kwi-Al2O3 + 3% TiO _ 2 izinto, kwaye amandla ebhondi yokuqina anokufikelela kwi-27.36MPa xa isixa seLao _ 2 yi-6.0 %. Ukongeza i-CeO2 eneqhezu lobunzima be-3.0% kunye ne-6.0% kwizinto ze-Cr2O3, Amandla okudibanisa okuqinileyo kwengubo phakathi kwe-18 ~ 25MPa, enkulu kuneyokuqala ye-12 ~ 16MPa Nangona kunjalo, xa umxholo we-CeO2 uyi-9.0%, i-tensile amandla bond ehla ukuya 12 ~ 15MPa.

2

Ukuphuculwa kokumelana nokothuka kwe-thermal yokwambathisa nge-ceramic ngomhlaba onqabileyo

Uvavanyo lokuxhathisa ukothuka kwe-Thermal luvavanyo olubalulekileyo lokubonisa ngokusemgangathweni amandla okudibanisa phakathi kokutyabeka kunye ne-substrate kunye nokutshatisa i-coefficient yokwandisa i-thermal phakathi kokwaleka kunye ne-substrate. Ibonisa ngokuthe ngqo amandla okugquma ukuxhathisa ukuxobula xa ubushushu butshintsha ngokutshintshatshintshayo ngexesha lokusetyenziswa, kwaye ikwabonisa ukukwazi ukugquma ukuxhathisa ukudinwa komatshini kunye nobuchule bokudibanisa kunye ne-substrate ukusuka ecaleni.Ngoko ke, ikwayinto ephambili ukugweba umgangatho we-ceramic coating.

Uphando lubonisa ukuba ukongezwa kwe-3.0% CeO2 kunokunciphisa i-porosity kunye nobukhulu be-pore kwi-coating, kunye nokunciphisa uxinzelelo loxinzelelo kumda we-pores, ngaloo ndlela kuphuculwe ukuxhathisa ukutshatyalaliswa kwe-thermal ye-Cr2O3 yokugqoka. Nangona kunjalo, i-porosity ye-Al2O3 yokwambathisa nge-ceramic yehla, kwaye amandla okubopha kunye nobomi bokungaphumeleli kobushushu bokutyalwa bunyuke ngokucacileyo emva kokongeza iLaO2. Xa isixa esongeziweyo seLaO2 sisi-6% (iqhezu lobunzima), ukuxhathisa ukothuka kwe-thermal kwengubo yeyona nto ilungileyo, kwaye ubomi bokungaphumeleli kwe-thermal bunokufikelela kumaxesha angama-218, ngelixa ubomi bokungaphumeleli kobushushu bokutya ngaphandle kweLaO2 yi-163 kuphela. amaxesha.

3

Iioksidi zomhlaba ezinqabileyo zichaphazela ukuxhathisa ukunxiba kweengubo

Iioksidi zomhlaba ezinqabileyo ezisetyenziselwa ukuphucula ukunyanzeliswa kweengubo ze-ceramic ubukhulu becala yi-CeO2 kunye neLa2O3. Isakhiwo sabo se-hexagonal layered sinokubonisa umsebenzi omhle wokuthambisa kunye nokugcina iimpawu zeekhemikhali ezizinzile kwiqondo lokushisa eliphezulu, elinokuphucula ngokufanelekileyo ukuxhatshazwa kokugqoka kunye nokunciphisa i-coefficient ye-friction.

Uphando lubonisa ukuba i-coefficient ye-friction ye-coefficient kunye nexabiso elifanelekileyo le-CeO2 lincinci kwaye lizinzile. Kuye kwaxelwa ukuba ukongeza i-La2O3 kwi-plasma etshizwe nge-cermet esekwe kwi-nickel-based cermet coating ngokucacileyo inokunciphisa ukuguga kwe-friction kunye ne-coefficient ye-friction ye-coefficient, kwaye i-coefficient ye-friction izinzile ngokuguquguquka okuncinci. Umphezulu onxityiweyo womaleko ogqunyiweyo ngaphandle komhlaba onqabileyo ubonisa ukuncamathela okunzulu kunye nokuqhekeka kwe-brittle kunye ne-spalling, nangona kunjalo, i-coating enomhlaba onqabileyo ibonisa ukuncamathela okubuthathaka kumphezulu ogugileyo, kwaye akukho phawu lwe-spalling yendawo enkulu. I-microstructure ye-microstructure ye-coat-doped enqabileyo yokugquma komhlaba ixinene kwaye ihlangene ngakumbi, kwaye i-pores iyancitshiswa, enciphisa amandla okukhuhla okuphakathi athwalwa ngamasuntswana amancinci kunye nokunciphisa ukukhuhla kunye nokunxiba i-Doping enqabileyo yomhlaba inokunyusa umgama we-crystal plane ye-cermets, ikhokelela. ekutshintsheni amandla okusebenzisana phakathi kobuso obubini bekristale kunye nokunciphisa i-coefficient ye-friction.

Isishwankathelo:

Nangona ii-oksidi zomhlaba ezinqabileyo zenze impumelelo enkulu ekusetyenzisweni kwezixhobo ze-ceramic kunye neengubo, ezinokuthi ziphucule ngokufanelekileyo i-microstructure kunye neempawu zomatshini wezinto ze-ceramic kunye neengubo, kusekho iipropati ezininzi ezingaziwayo, ngakumbi ekunciphiseni ukungqubuzana kunye nokugqoka. amandla kunye nokunxiba ukuxhathisa izixhobo ukusebenzisana kunye neempawu zabo zokuthambisa iye yaba ulwalathiso olubalulekileyo olufanele ingxoxo kwinkalo tribology.

Umnxeba: +86-21-20970332I-imeyile:info@shxlchem.com

Ixesha lokuposa: Sep-02-2021